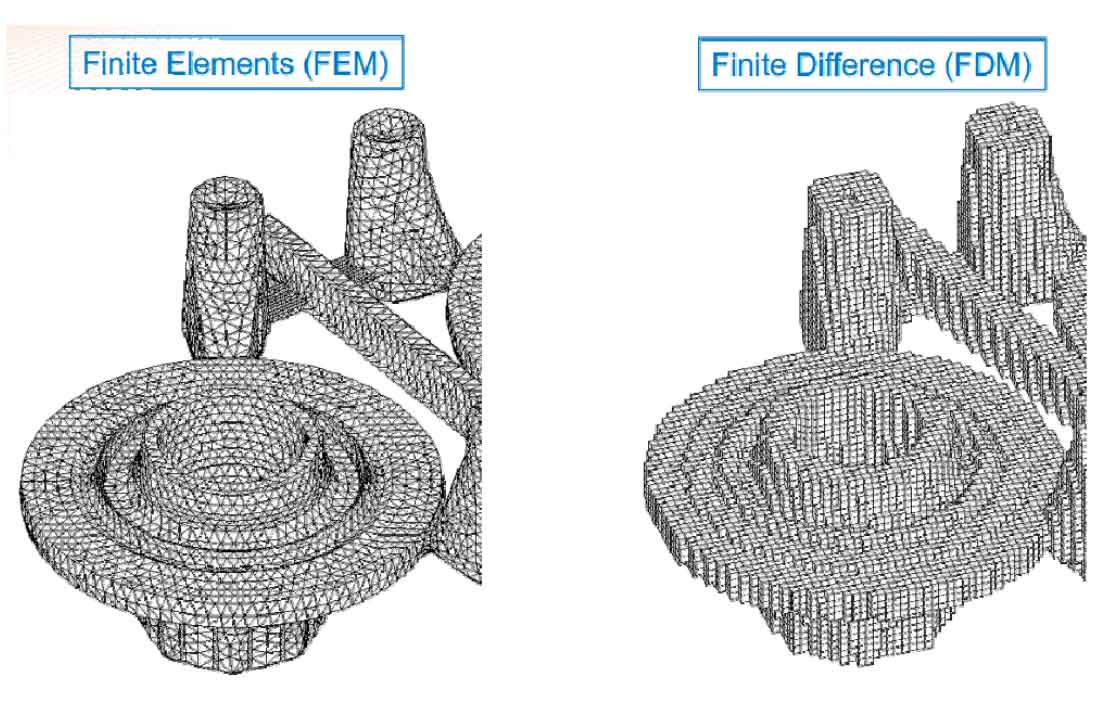

The methods for solving the differential equation of heat conduction in solidification process mainly include finite element method (FEM), finite difference method (FDM) and BEM boundary element method (BEM), according to different discretization methods.

FEM is an algorithm evolved from the classical variational method. It can divide irregular meshes and has good adaptability to complex geometry. The mesh can calculate the stress of deformation. The number of meshes is small, the storage memory is small, and the pre-processing and post-processing can be carried out quickly. Moreover, the finite element mesh is universal. FEM is a flexible and accurate method, which is suitable for complex Thin wall lost foam castings are simulated and analyzed, but the finite element mesh processing is complex and difficult.

Compared with FEM, FDM mesh processing is convenient and efficient. This method is the most widely used in software application. This method is mostly used in general commercial lost foam casting process simulation systems, but the finite difference mesh is square, the description of complex geometric contour is less realistic, and it can not be used for stress calculation or stress coupling calculation by other algorithms.

BEM is the latest numerical analysis method developed after FEM, which only takes the geometric boundary of lost foam casting as the analysis object. When solving with BEM, it only needs to divide the boundary element, which is much more convenient than other methods. As a rapidly developing numerical simulation method, BEM has also begun to move towards the mature stage of application. The software applying BEM is also developing from the monotonous single problem solving program in the early stage to the multi-functional BEM comprehensive software package such as comprehensive pre-processing and post-processing.

The ProCAST casting process simulation system selected is developed based on FEM. It is the only commercial simulation software package in the world that can carry out three field full coupling analysis of lost foam casting process. In the development and production of complex thin-wall lost foam casting, near net shape lost foam casting can show its ability and function.