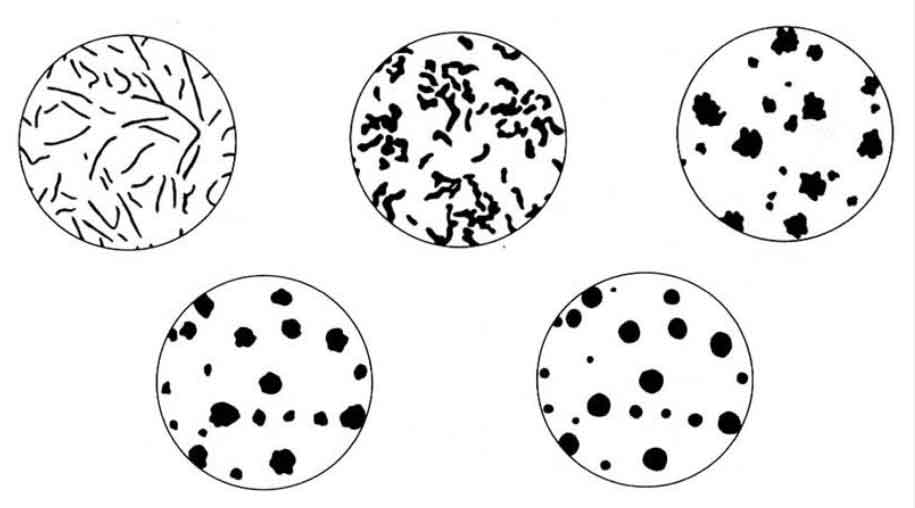

Spheroidal Graphite Iron, also known as ductile iron or nodular iron, has indeed revolutionized the manufacturing of lightweight parts in the automotive industry. Spheroidal Graphite Iron is a type of cast iron that is characterized by its unique microstructure, which consists of graphite nodules or spheroids embedded in a matrix of ferrite and pearlite. This microstructure provides Spheroidal Graphite Iron with exceptional mechanical properties, making it an excellent material choice for a wide range of automotive components.

Here are some key aspects of how Spheroidal Graphite Iron has contributed to lightweight part manufacturing in automotive engineering:

- Strength-to-Weight Ratio: Spheroidal Graphite Iron offers a remarkable strength-to-weight ratio, meaning it provides high strength while being relatively lightweight. This makes it ideal for applications where weight reduction is crucial without compromising structural integrity or safety. Compared to traditional cast iron, SGI can provide up to 30% weight savings.

- High Tensile Strength: Spheroidal Graphite Iron possesses excellent tensile strength, allowing it to withstand high loads and stresses. This makes it suitable for critical automotive components such as engine blocks, cylinder heads, crankshafts, and suspension parts.

- Fatigue Resistance: Spheroidal Graphite Iron exhibits superior fatigue resistance, which is vital for components subjected to cyclic loading, such as crankshafts and connecting rods. Its unique microstructure helps prevent crack propagation, increasing the longevity and reliability of the parts.

- Damping Properties: Spheroidal Graphite Iron has excellent vibration damping properties, which is beneficial for automotive applications. It helps reduce noise, vibration, and harshness (NVH) levels, resulting in improved driving comfort and reduced noise pollution.

- Machinability: Spheroidal Graphite Iron is relatively easy to machine compared to other materials with similar strength properties, such as aluminum alloys. This facilitates the manufacturing process, reducing costs and production time.

- Thermal Conductivity: Spheroidal Graphite Iron has good thermal conductivity, allowing efficient dissipation of heat generated in components like engine blocks. This property helps in maintaining optimal operating temperatures, improving engine performance and longevity.

- Cost-Effectiveness: Spheroidal Graphite Iron offers a cost-effective solution for lightweight part manufacturing in the automotive industry. It provides a balance between performance, weight reduction, and cost, making it an attractive alternative to more expensive materials like aluminum.

Due to these advantages, Spheroidal Graphite Iron has found widespread use in various automotive applications. Its use has expanded beyond traditional applications to encompass lightweight components that contribute to fuel efficiency, emission reduction, and improved vehicle dynamics.

It’s important to note that while Spheroidal Graphite Iron offers numerous benefits, the selection of materials in automotive engineering depends on specific design requirements, cost considerations, and other factors. Different materials, such as aluminum alloys, high-strength steels, and composites, continue to play important roles in lightweight part manufacturing as well.