Steel casting plays a crucial role in powering heavy machinery used in various industrial applications. This article explores the significance of steel casting in the manufacturing of heavy machinery, highlighting its advantages, applications, and contributions to the efficiency and durability of industrial equipment.

- Strength and Durability: Heavy machinery requires robust components capable of withstanding extreme operating conditions and heavy loads. Steel casting provides exceptional strength and durability, making it ideal for critical parts such as frames, gears, rollers, and housing assemblies. The inherent strength of steel castings ensures reliable performance and longevity in demanding industrial environments.

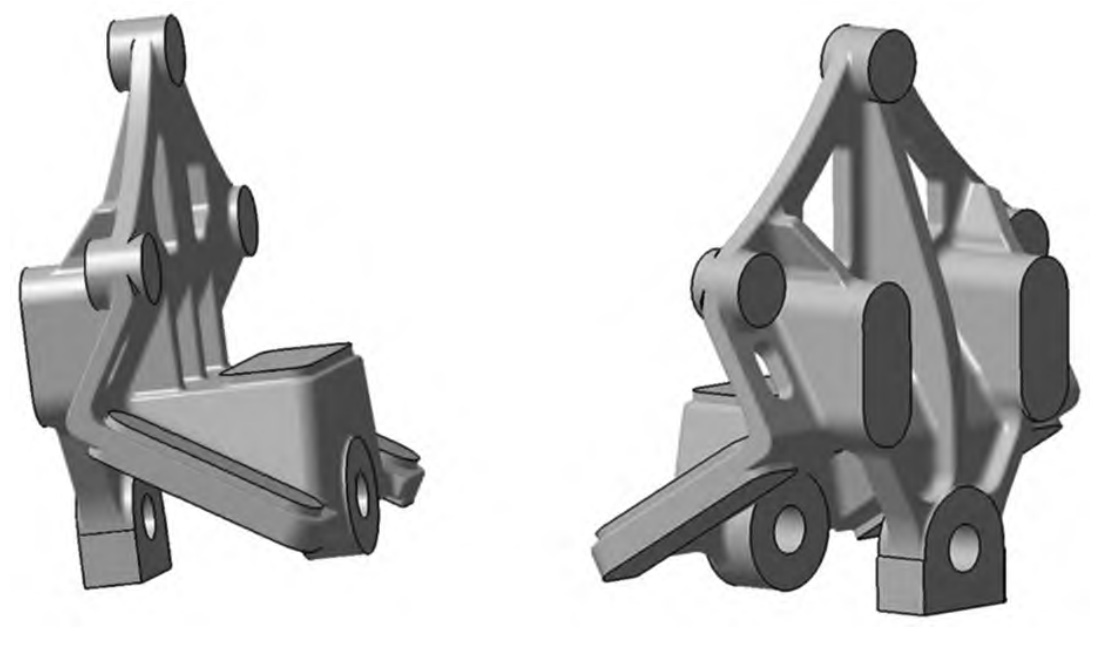

- Customization and Complex Geometries: Steel casting offers flexibility in design and allows the creation of complex shapes and geometries. Heavy machinery often requires intricate components tailored to specific applications. Steel casting enables the production of customized parts with precision, ensuring optimal fit, functionality, and performance. Complex geometries can be achieved through casting processes like investment casting or sand casting.

- Weight Reduction and Fuel Efficiency: In heavy machinery, weight reduction plays a crucial role in improving fuel efficiency and overall machine performance. Steel castings offer the advantage of high strength-to-weight ratio, allowing for the production of lightweight components without compromising structural integrity. By reducing weight, steel castings contribute to fuel efficiency, operational cost savings, and increased productivity.

- Wear Resistance and Toughness: Heavy machinery components are subject to high levels of wear, abrasion, and impact. Steel castings can be engineered with specific alloy compositions to enhance wear resistance and toughness, ensuring longer service life and reduced maintenance requirements. Abrasion-resistant steel castings are widely used in applications such as mining equipment, excavators, and crushers.

- Temperature and Corrosion Resistance: Industrial machinery often operates in harsh environments characterized by high temperatures, corrosive chemicals, and exposure to elements. Steel castings can be manufactured using specialized alloys that exhibit excellent heat resistance and corrosion resistance properties. This makes them suitable for applications such as furnace components, chemical processing equipment, and power generation machinery.

- Reliability and Safety: Heavy machinery is relied upon for critical industrial operations, and safety is of utmost importance. Steel castings undergo rigorous quality control processes, including non-destructive testing and metallurgical analysis, to ensure reliability and integrity. High-quality steel castings provide a robust foundation for heavy machinery, minimizing the risk of failure and ensuring safe operation.

Steel casting plays a vital role in powering heavy machinery used in various industrial applications. With its strength, durability, customization capabilities, and resistance to wear, temperature, and corrosion, steel castings provide the foundation for efficient and reliable industrial equipment. Whether in mining, construction, energy, or manufacturing, steel castings enable heavy machinery to perform under demanding conditions, contributing to increased productivity, cost savings, and enhanced safety in industrial operations.