Steel casting plays a pivotal role in the construction industry, enabling the creation of strong, durable, and sustainable structures. This article explores the importance of steel casting in construction, highlighting its benefits in structural integrity, design versatility, cost-effectiveness, and environmental sustainability.

- Structural Integrity and Strength: Steel castings provide exceptional structural integrity and strength, making them an ideal choice for constructing buildings, bridges, and other infrastructure projects. The high tensile and compressive strength of steel castings ensure the ability to withstand heavy loads, seismic forces, and harsh environmental conditions, ensuring the longevity and safety of structures.

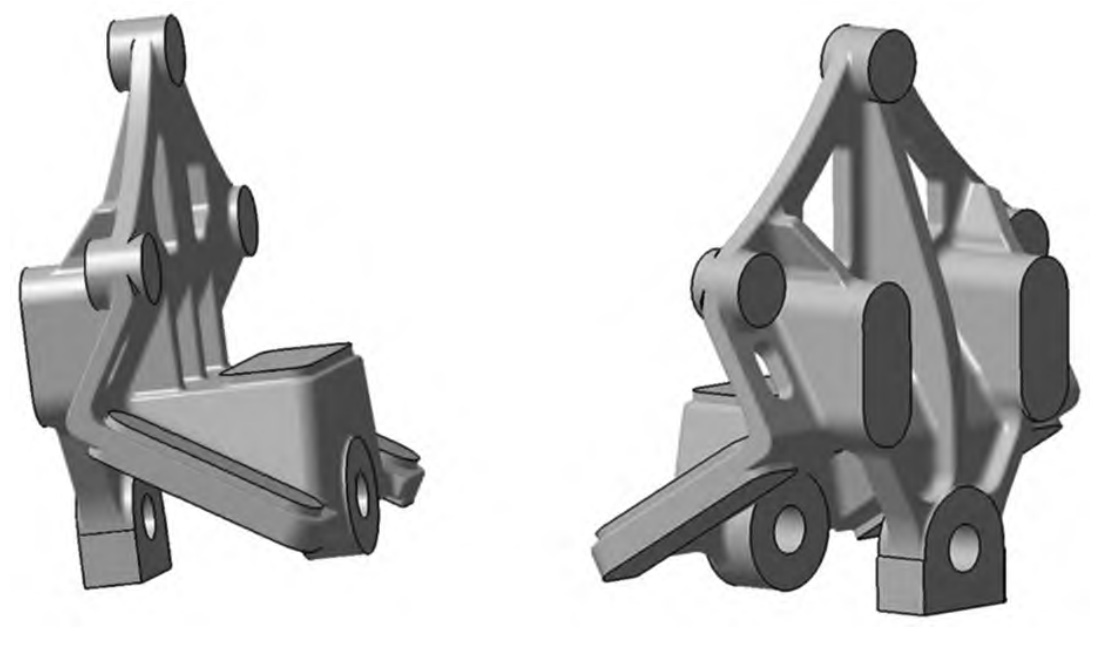

- Design Versatility and Flexibility: Steel casting offers design versatility and flexibility, allowing architects and engineers to create innovative and complex structures. Its ability to be cast into various shapes and sizes enables the construction of intricate components, curved structures, and customized architectural features. Steel casting allows for greater design freedom, enabling the realization of unique and visually appealing structures.

- Cost-Effectiveness and Efficiency: Steel casting provides cost-effective solutions in construction projects. By using precision casting techniques, near-net shape components can be produced, minimizing material waste and reducing machining and assembly costs. Steel castings also offer faster production times compared to other manufacturing methods, contributing to overall project efficiency and cost savings.

- Sustainable Construction: Steel casting promotes sustainability in construction. Steel is a highly recyclable material, and steel castings can be recycled and reused at the end of a structure’s life cycle. Additionally, the durability and long lifespan of steel castings reduce the need for frequent replacements, minimizing material consumption and waste generation. Using steel castings in construction aligns with green building practices and contributes to the reduction of environmental impact.

- Resistance to Corrosion and Fire: Steel castings exhibit excellent resistance to corrosion and fire, enhancing the safety and longevity of structures. Corrosion-resistant steel castings are commonly used in coastal and humid environments, where exposure to moisture and salt is a concern. Steel castings also have inherent fire-resistant properties, providing structural stability and protection in the event of a fire.

- Construction Efficiency and Time Savings: Steel castings offer advantages in construction efficiency and time savings. The prefabrication of steel components in controlled manufacturing environments allows for faster on-site assembly, reducing construction timelines. Steel castings can be fabricated off-site while site preparation and foundation work are in progress, enabling concurrent construction activities and accelerating project completion.

Steel casting plays a vital role in constructing strong, durable, and sustainable structures in the construction industry. From ensuring structural integrity and design versatility to promoting cost-effectiveness, environmental sustainability, and construction efficiency, steel castings contribute to the development of resilient and visually appealing buildings and infrastructure. By utilizing steel castings, the construction industry can achieve long-lasting, sustainable structures that meet the evolving demands of modern construction practices.