When designing the structure of sand castings, we should not only consider the requirements of mechanical properties and working performance, but also consider the requirements of sand casting process and casting alloy properties on the structure of castings. Whether the structure of sand casting is reasonable, that is, whether its structure and processability are good, has a great impact on the quality, production efficiency and cost of sand casting. Some defects such as cracks, shrinkage cavities and pores in sand castings are caused by the influence of casting structure.

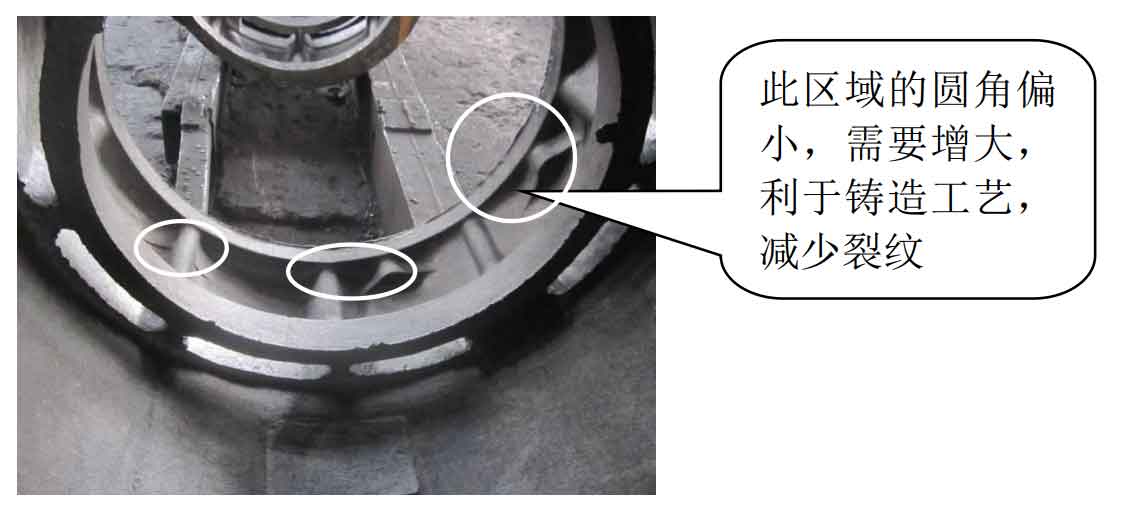

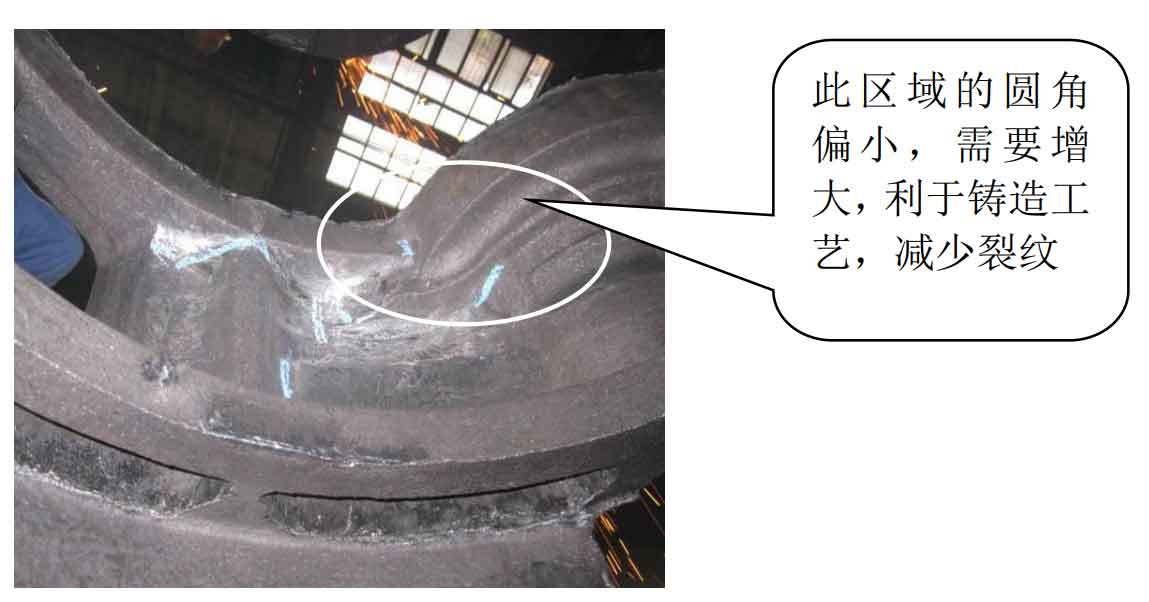

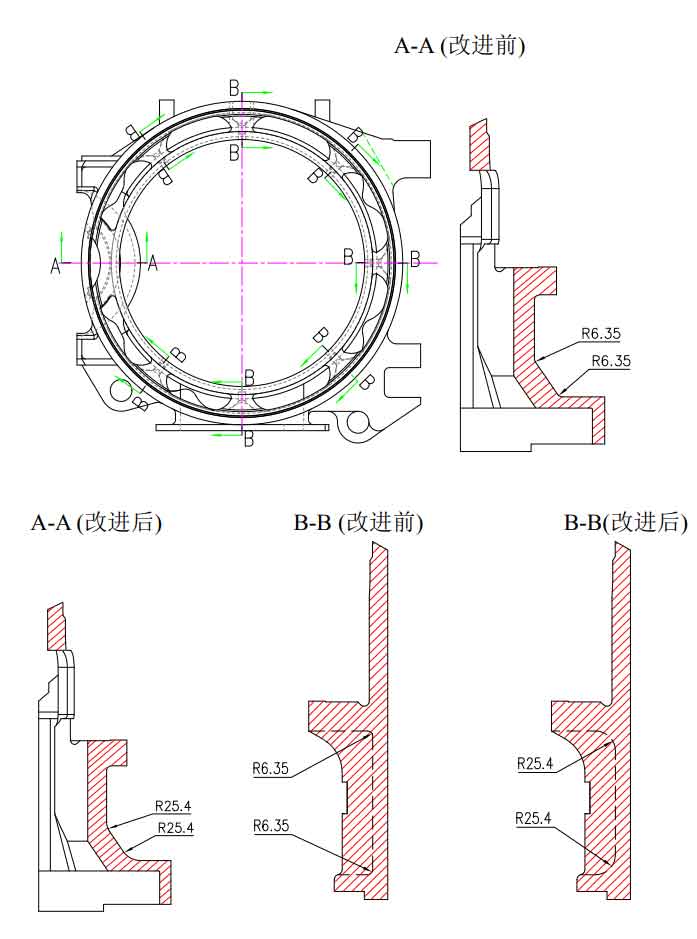

After the furan resin sand casting process was optimized into alkaline phenolic resin sand casting process to produce motor shell, the crack at the fillet of core 2 is still serious, and the structure of sand casting has a direct impact on the crack. By analyzing the product drawings, it can be seen that the fillet at the intersection of the inner circle and the horizontal plane and the fillet at the root of the semicircle arc (as shown in Fig. 1 and Fig. 2) are too small, which is easy to cause stress concentration, which is an important reason for the crack defects in this part. After analyzing the assembly of the product, it is found that properly increasing the fillet of this part will not have any impact on the assembly and will not cause the quality problems of sand casting. After communicating with the sand casting design engineer, the fillet of this part will be changed from R6 Replace 35 with R25 4. See Figure 3 for details. Properly increasing the round corner of sand mold casting is very conducive to the implementation of sand mold casting process, and can reduce the tendency of crack defects at the round corner.