The surface roughness is measured by using the TR200 handheld roughness meter of Beijing Times Instruments, and the roughness is expressed by the arithmetic average deviation Ra of the machined surface profile. 12 groups of surface roughness values are measured under each cutting parameter, and the average value is taken as the machined surface roughness under this parameter after removing one highest value and one lowest value.

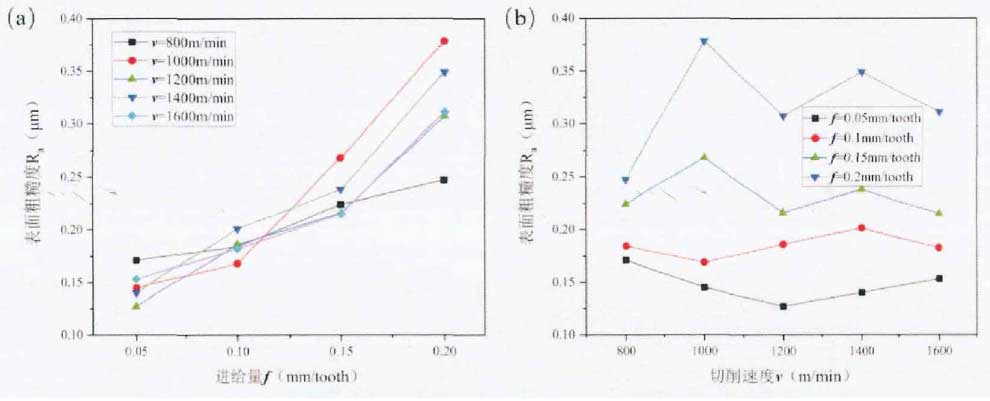

As shown in the figure, the changes of surface roughness values under various cutting parameters are measured. It can be seen from figure (a) that at a certain cutting speed, the roughness increases with the increase of feed, which is consistent with the results of surface topography analysis of the upper section. When the feed rate increases, the height of the machining residual area increases, according to the formula of the residual area height, f increases, Rmax increases accordingly, and the surface roughness increases accordingly. In addition, combined with the analysis of cutting force, the feed rate increases, the cutting force increases, and the vibration in the cutting process intensifies, which leads to the increase of surface roughness, and the surface roughness fluctuates greatly with the change of cutting speed.

According to figure (b), on the whole, the fluctuation of surface roughness with cutting speed is small, and the smaller the feed is, the smaller the fluctuation is. When f=0.2mm/tooth, the fluctuation of surface roughness at each cutting speed is the largest, due to the increase of feed, cutting force and vibration, which leads to greater fluctuation of surface roughness, which is consistent with the analysis. In addition, a better surface roughness can be obtained at the cutting speed of 1200m/min.