Structural and quality requirements for box-type bed

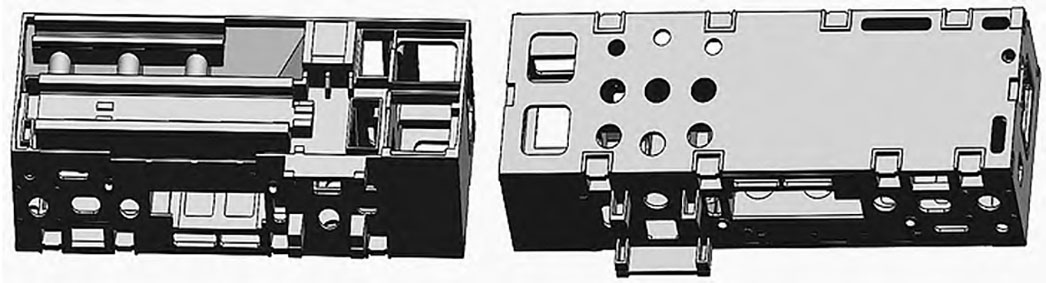

The specific structural diagram of the box-type bed is shown in the figure, and the material is HT300, the casting weight is 2989kg, and the product outline dimensions are: 3100mm×1265mm×785mm, main wall thickness of the casting is 15 mm, with a maximum wall thickness of 90mm and a minimum wall thickness of 15mm. The casting should The machined surface shall be free of defects such as sand inclusion, air hole, slag inclusion, cold shut, etc. The cavity part cannot have defects, and the hardness of the guide rail must be greater than 183 HBN, no quality problems such as loose organization and unqualified hardness are allowed Other appearance surfaces shall not have obvious sand holes, sand sticking and bulging. Such defects as blisters and other defects affecting the appearance quality.

Analysis of the original process and casting quality problems

For the technical quality requirements of this casting, we adopt The process method of taking the guide rail surface down and the bottom and oil tank surfaces facing up, Meanwhile, the casting is entirely on the upper box surface, with a filter screen placed under the runner to reduce Less dirt such as slag will flow into the cavity, and the internal runner will be blocked from the guide rail surface and important The introduction of the processing plane ensures that the iron enters the mold cavity smoothly and evenly. This ensures the stability of the internal sand core and facilitates dimensional control, while also which is beneficial to the shrinkage of the risers.

(1) Smelting parameters

The melting temperature of molten iron is not higher than 1380℃, and the overheating temperature is 1490~1510℃, casting temperature controlled at 1370~1390℃. Use a two-stage inoculation tank for inoculation treatment, with inoculant of 0.5% SiFe (grain size of 3~10mm). Add 0.1% of SiFe in the ladle during casting. SiFe (particle size of 3~10mm) is used for float silicon inoculation to ensure the quality of the casting. The Si content of the component is controlled at 1.7% to 1.8%, and the C content is controlled at 3.05% to 3.15%.

(2) Pouring system

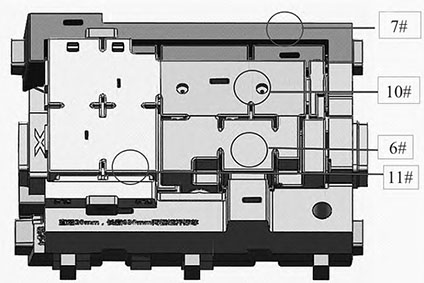

The open bottom pouring system is adopted, and the internal runner is guided from the bottom surface. The specific layout is shown in Figure 2. The proportion of the pouring system is: ΣF straight : ΣF transverse :ΣF inside =1:1.56:1.53, sprue with diameter of 90mm, runner (105mm+84mm)×105mm, internal runnerø35mm×4 /ø50mm×3 (ø35 cross-sectional area of 3848mm2, ø50 cross-sectional area of The process uses 8 S100mm and 2 S80mm spherical feeder, without chills.

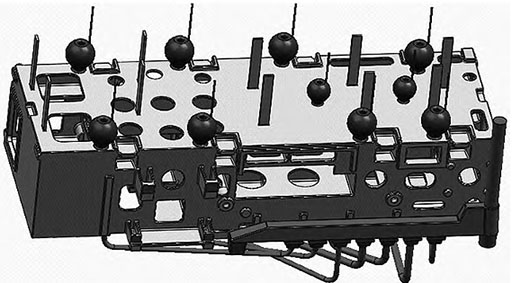

Quality problems of castings

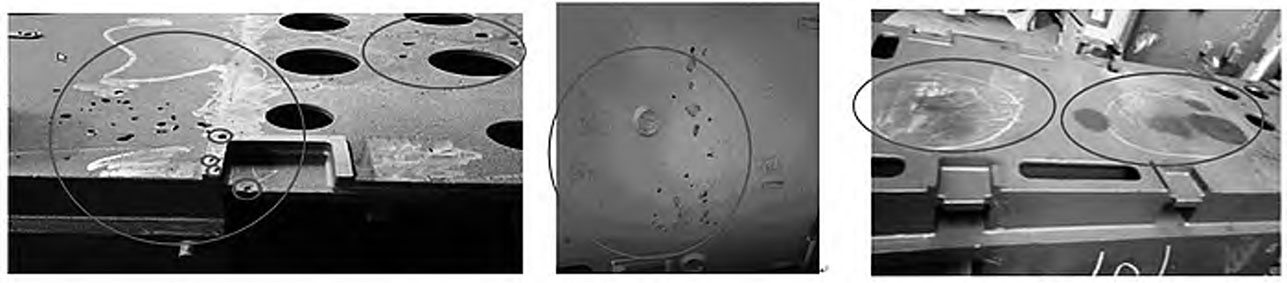

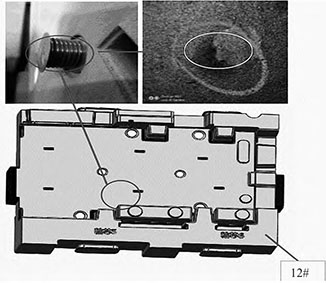

(1) 13 castings were produced according to the above process, and 4 of them were hardened. The hardness is 164~176HBN, which is lower than the customer’s requirements. After metallographic examination, it was found that the pearlite content was only 80%~90%, and the other products with acceptable hardness The hardness of the product is also concentrated at 180-185 HBN, which poses a relatively high risk. (2) The upper box surface of the produced castings has a lot of sand inclusion, and basically every casting has The need for welding repair increases the difficulty of subsequent cleaning and the cost of rework. (3) During the casting process, there is a serious risk of fire due to the production process described above. Due to the fire, 7 pieces were scrapped, resulting in a scrap rate of 53.8%. The photo of the casting after the fire is shown in the figure, and the area circled is the The body chokes and the core supports have poor fusion, and the PT test after welding repair is not satisfactory. It’s grid.

Cause analysis

(1) The casting material is HT300, due to large wall thickness deviation, Slow pouring and low pouring temperature, in an open pouring system Castings under the system are prone to cold shut, loose structure, and hardness mismatch. Due to structural reasons, the same material of molten iron is poured into other products The quality is relatively stable, but there is a hardness problem on this product. Unqualified quality problems. The lack of pearlite is likely to be caused by The chemical element content generated in the pearlite is not enough, and the CE value Too high also promotes the formation of ferrite.

(2) The main reasons for the sand inclusion problem on the upper box surface are: First, due to the The box surface is flat, the core gap is small, the core coating layer is not well controlled, and there is sand rubbing during the core placement process. In addition, there are few overflow risers on the upper box surface, which leads to poor casting quality. It is easy to have slag inclusion after injection. Secondly, due to the special structure of the casting, The weight reduction holes and threading holes on the upper tank surface are concentrated on one end, on one side of the fuel tank There are almost no weight reduction holes. In the actual production process, there are more core supports used, The core is prone to sanding, and the scattered sand cannot be cleaned thoroughly, resulting in sand inclusion in the casting.

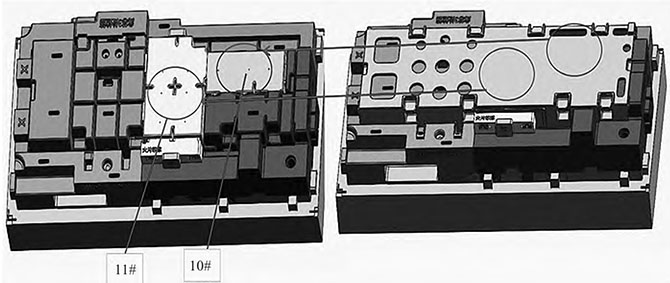

(3) The tendency of choking during pouring occurred in 10#, The location of the 11# core is shown in Figure 4. There are The core head is fixed, and the upper side is completely supported by the core support, with a contact surface The two sand cores are too large to be effectively fixed, and they are impacted by the molten iron the riser, there is a risk of vibration that may cause choking problems.

(4) After using ordinary core supports, there is poor fusion due to the pouring Note that there have been cases of regional casting where the casting temperature cannot be effectively guaranteed. This leads to poor fusion of the core support, as shown in the figure.

Process improvement measures and results

(1) Improvement of smelting process

Since increasing the proportion of scrap steel is beneficial to the hardness of castings, During the melting and batching of molten iron, the proportion of scrap steel was appropriately increased; in order to To ensure the content of pearlite, the control median of Mn was increased from 0.65% to 0.95%, and the control median of C was reduced from 3.12% to 3.07%, and the control median of Si decreased from 1.75% to 1.71%; Note: The temperature is adjusted to 1380-1400℃, and other melting parameters are kept remains unchanged.

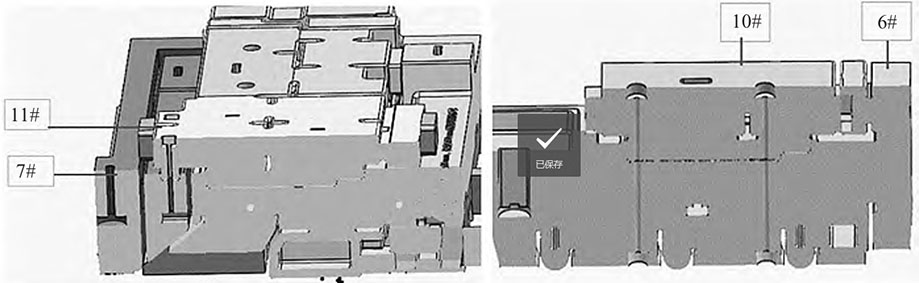

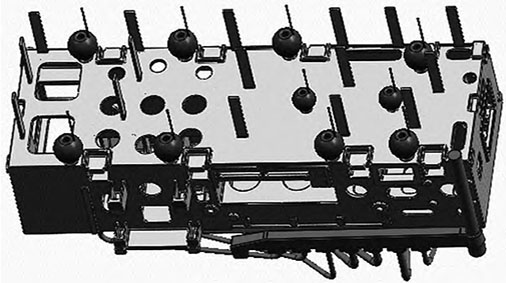

(2) Improvement of casting process Due to the particularity of the casting structure, the original 3D process is adopted After the core is inserted, the top core support method for the top surface cannot be effectively used for 8# and 11# sand cores. Fix, 12# core is fixed by pressing the core support to fix 8# and 11# sand cores, The problem of choking caused by the shaking of the sand core during casting cannot be completely solved. At the same time, it is easy to rub sand, resulting in sand inclusion in the casting. In order to completely solve the problems of choking and poor fusion of sand inclusion, this product has been directly modified to 3D printing core production method. The sand core is produced using the “core marking method”. 8# and 11# sand cores that are difficult to fix are designed to be The method of embedding the screw is to use the screw to connect the 6# core and the 10# sand before inserting the core. The cores are connected and fixed together, and the 7# sand core is first embedded with a Ø20 Two 650 mm long poles, with 11# core passing through 7# sand The core screw is used to secure it. By marking the core, the use of core supports is reduced. As shown in Figure 6, the gap between the remaining sand cores is 1 mm. Adjusted to 1.5 mm. The overflow riser on the upper box surface has been increased from the original 10 to 16, the air outlet area is increased by 5850 mm2, The body is shown in Figure 7. After using the 3D printing core marking process, it is produced into The production cost will be significantly reduced, the process operation is simple, and the casting quality will be improved. The production efficiency on site has been significantly improved due to the The precision of the sand core is high, the surface quality is good, and the gap during the core assembly process is suitable. The skin seam of the casting is small, and the appearance quality of the casting has been significantly improved.

Improvement results

40 pieces of the product were continuously produced according to the improved process, The pearlite content in the matrix structure of the casting is ≥95%, and the tensile strength 315-335 MPa, with a hardness of 183-192 HBN, which meets the customer’s requirements for material quality. At the same time, the casting process is stable, The pouring temperature was 1380~1400℃, and there was no choking phenomenon. The casting did not have defects such as slag inclusion, sand inclusion, and poor fusion of the core support. The improvement effect was significant. The result is very obvious, the waste rate is controlled below 1.5%.

Conclusion

The production of box-type bed has its own special features. After a long period of and gradually summarized a set of experiences on thin-walled box-type casting of fuel tanks. production process and applied to production practice. Its main content There are: The process uses no core support in the oil tank area, with the casting entirely on the upper tank, with a filter screen placed under the runner; in order to ensure the content of pearlite, strict The content of Mn, C, Si is controlled by the gradient control; the pouring temperature is ensured to be 1380℃ Above all, the crates can be lifted and transported after 72 hours.