The important roll part of an equipment, which was originally a welded part, is now changed into a ductile iron part for trial production. According to the customer’s requirements, the material shall comply with DIN en1563:2012-3 casting – ductile iron, brand en-gjs-400-18u-rt, and the size of cast test block shall be 200 mm × 200 mm × 200 mm. The mechanical properties and metallographic structure of nodular graphite castings need to be checked on the axial samples at both ends of the body. The mechanical properties of the body are required to be RM ≥ 350 MPa, Rp0.2 ≥ 230 MPa, a ≥ 10%. 100% of nodular graphite castings need ultrasonic and magnetic particle flaw detection; 100% penetrant flaw detection for shafts at both ends. The trial production of large nodular cast iron roll is introduced from nodular casting process, melting process and production results.

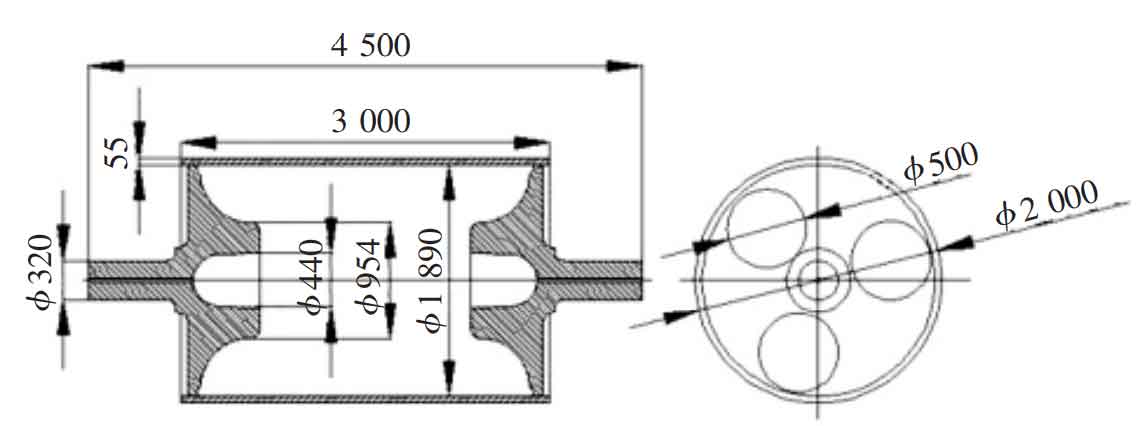

The roll structure is shown in Figure 1, and the overall dimension is φ 2 000 mm × 4500 mm, the weight of nodular cast iron is about 19 T, the main wall thickness of roll body section is 55 + 5-1mm, and the diameter of shafts at both ends φ 320 mm. The wall thickness shall be tested by ultrasonic after processing, and the wall thickness shall be uniform; If the wall thickness is uneven, it will seriously affect the counterweight weight weight of dynamic balance. The roll weight is large, the wall thickness is required to be uniform, and the production technology is difficult.

Although the main wall thickness of the roll is 55 mm ~ 107 mm, the thickest part φ 320 mm, which can also be regarded as thick large section ductile iron. Graphite floating, graphite flowering and fragment graphite often appear in the production of thick and large section ductile iron, which directly affects the mechanical properties and metallographic structure of the body sample. The roll contour size is large, and the hot section thickness at the connection between the upper and lower flanges and the roll body is large. A suitable gating system and feeding system must be designed to make the molten iron filling stable and fast, the solidification of nodular graphite casting balanced, and the feeding good, so as to prevent casting defects such as sand flushing, slag inclusion, shrinkage cavity, shrinkage porosity and so on. If the design of the gating system is unreasonable and the molten iron is not effectively filtered, it is easy to produce slag inclusion defects near the upper flange. Therefore, a filter screen is placed at the connection between the bottom of the runner and the ceramic pipe.

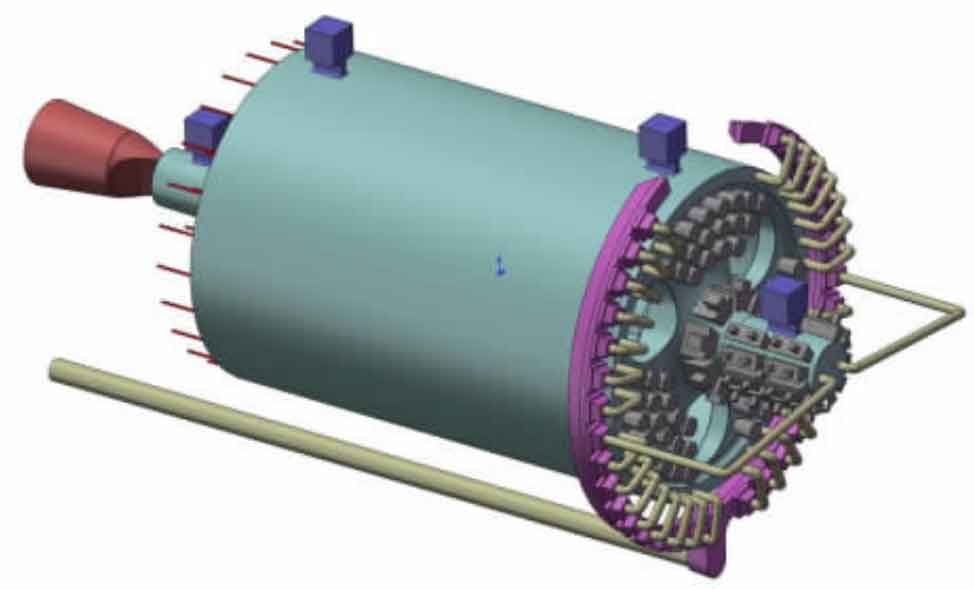

When designing the nodular graphite casting process, the computer is used for solidification simulation, and the size and position of the riser and chill are adjusted according to the solidification simulation results and experience, so as to finally obtain a satisfactory solidification simulation result. The roller nodular graphite casting process is shown in Figure 2. The gating system adopts the bottom injection type, the pouring time is 120 s, and the sprue adopts φ 120 ceramic tube, proportion of each component of gating system f straight ∶ f transverse ∶ f inner = 1 ∶ 2 ∶ 1.2

A ceramic pipe is placed on the flange end face of the upper end of the roll as a concealed riser. Enlarge the riser at the top of the upper shaft for feeding. Considering that there are thick and large hot joints near the upper flange, shrinkage cavities caused by insufficient feeding are most likely to occur. In order to improve feeding efficiency and achieve good feeding effect, a feeding system combining cold iron and riser is adopted.

By analyzing the roll structure in detail, the possible problems are fully considered in the design of ductile iron casting process, and the ductile iron casting process is continuously improved combined with the results of computer simulation. In the molding process, the uniformity of cavity is controlled to achieve the purpose of uniform wall thickness. At the same time, selecting appropriate chemical composition and strengthening spheroidizing inoculation treatment can stably produce rolls with high requirements.