1.Problem description

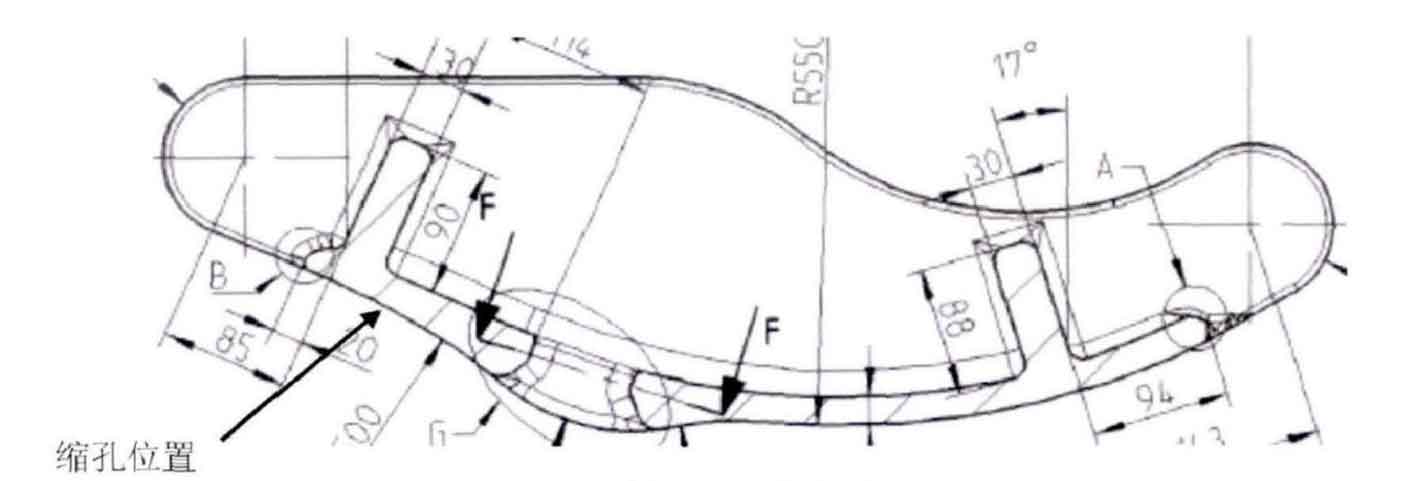

Sand casting boom steel casting, steel casting No. 322232642, is an accessory of atlas process engineering machinery rock drill in the Netherlands. During the sampling inspection of small batch production after the preliminary trial production is qualified, it is found that some products have shrinkage defects locally, and the casting defect parts are shown in Figure 1. The photos of casting defects after gas trauma are shown in Figure 2. From the figure, it can be seen that there are shrinkage defects inside the product. The three-dimensional simulation of the original process is investigated, and the simulation results show that there is no shrinkage defect in this part.

2.Cause analysis

The early test products of the steel casting have been confirmed to be qualified by ultrasonic testing and radiographic testing. In the subsequent small batch production, only some products have shrinkage defects. The reasons and methods of machine defects are divided into five aspects: environment and personnel.

After analysis, there are only two reasons for the shrinkage of the product; One is improper operation, the other is unreasonable design of sand casting process. Investigate the actual production situation, eliminate the possibility of improper selection of sand box, improper placement of cold iron, incomplete pressure core, blocked outlet channel and other factors, and determine that the cause of shrinkage cavity of the casting is still a problem in process design.

Since there is no recent change in sand casting process, the reason for the defects points to the unreasonable design of sand casting process. After carefully checking the sand mold casting process, it is confirmed that there are no problems in the riser size, riser seat shape and size and cold iron design.

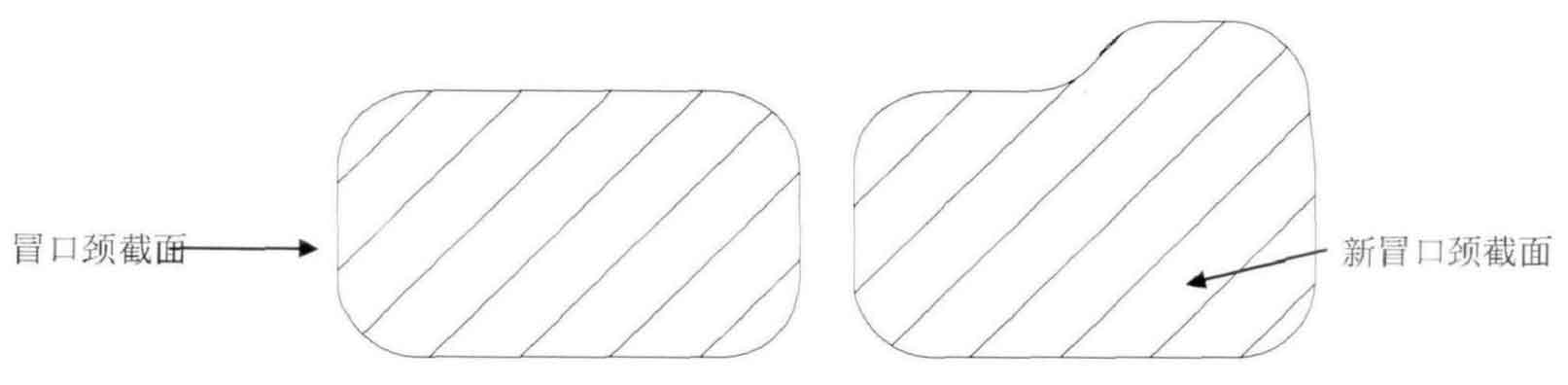

After checking the sand casting structure and process again, it is speculated that although the riser neck modulus of the side riser of sand casting meets the process design standard, the section shape of the riser neck does not adapt to the product structure due to the special local structure of the feeding product.

The section shape of riser neck is unreasonable, which will lead to the riser can not feed the casting smoothly, resulting in shrinkage cavity and porosity.

Because the unreasonable shape of riser neck is not very serious, not every casting has shrinkage cavity. There is no shrinkage cavity in sand mold casting poured at a lower temperature, and the products poured at a lower temperature may have shrinkage cavity defects. The unreasonable shape of riser neck is not serious, which is also the reason why there is no shrinkage defect in three-dimensional simulation.

Therefore, the reason for the shrinkage defect in sand casting is the unreasonable design of the riser neck of the side riser.

3.Countermeasure formulation and verification

Change the sand casting process and adjust the size of riser neck, as shown in Figure 3. The locally increased riser neck can ensure the timely and effective feeding of the riser to the thicker part of the steel casting.

Change the mold for trial production. The test products and subsequent mass-produced steel castings are qualified through ultrasonic flaw detection and radiographic flaw detection. The shrinkage defect is eliminated, and the qualified steel castings are shown in Figure 4.

4.Improve harvest

When setting the riser in the area close to the casting process manual, it shall not be set according to the size of the casting structure and the riser. It is feasible to eliminate the shrinkage defects of steel casting boom by adjusting the shape and size of riser neck.