1. Sample preparation

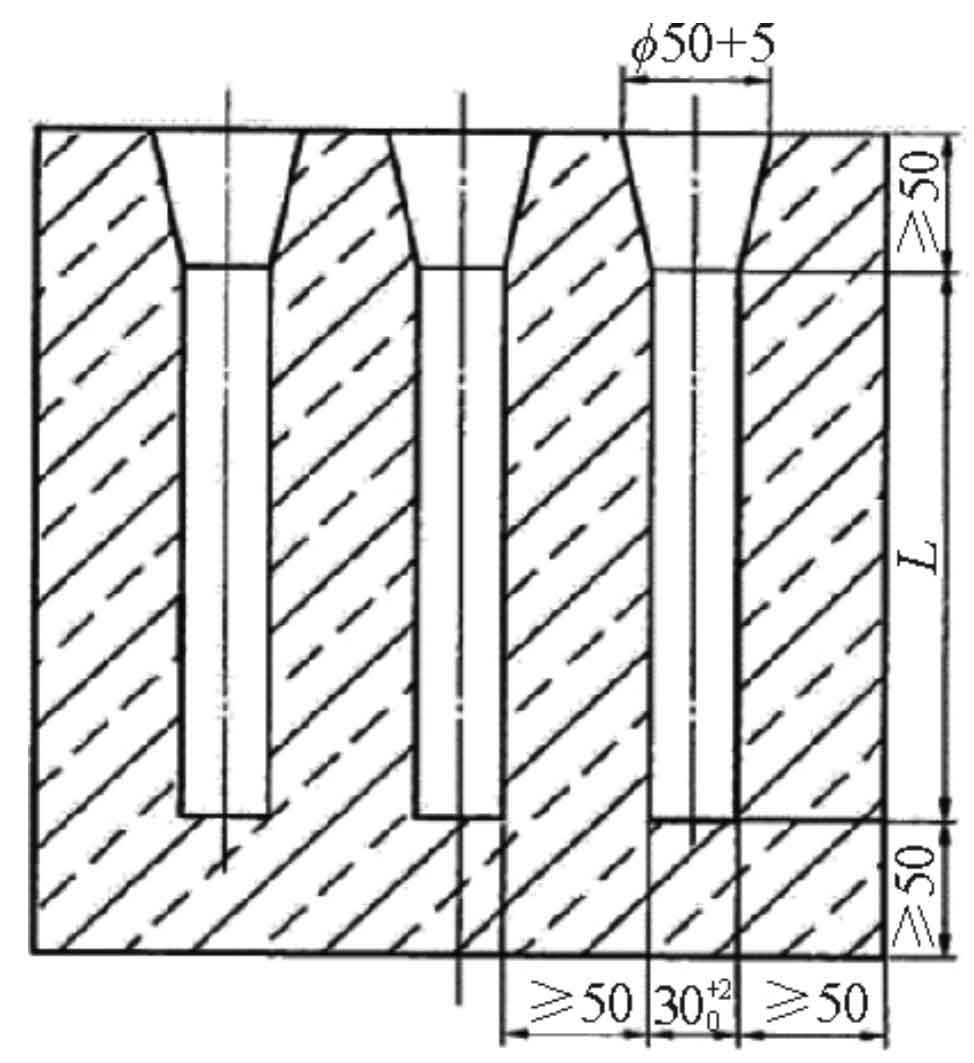

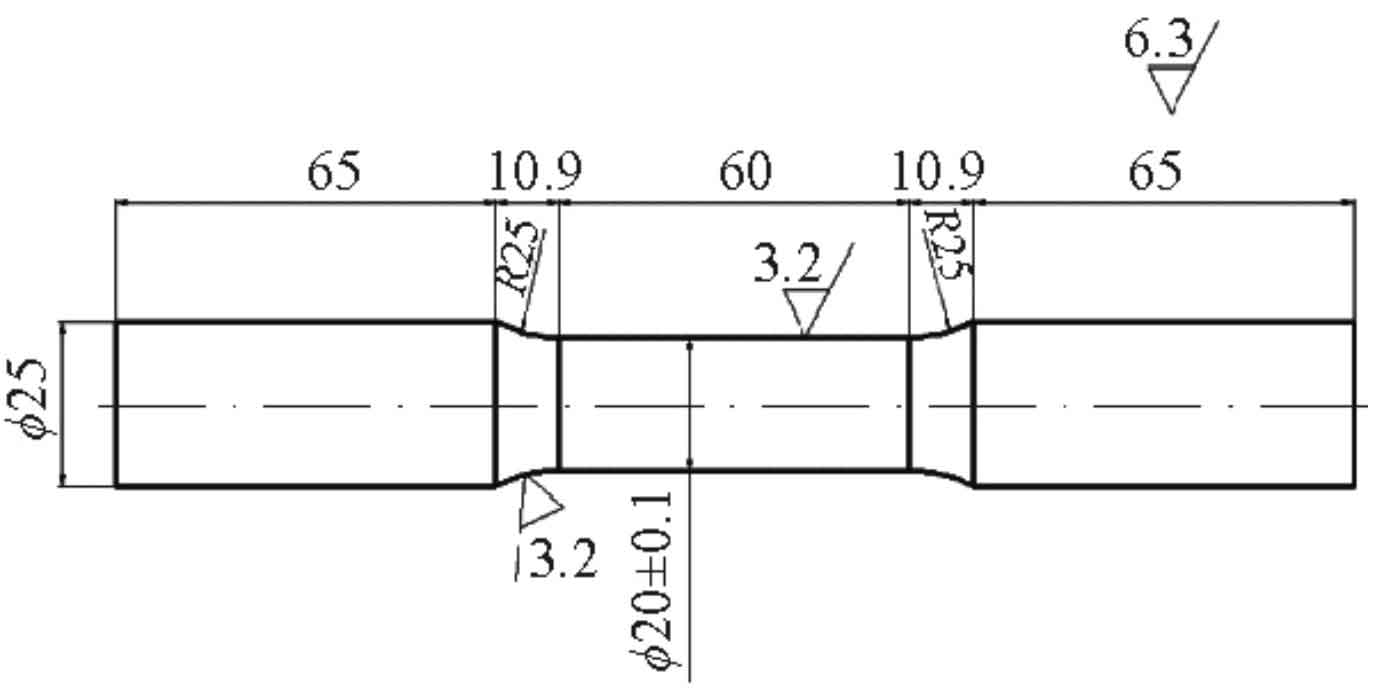

According to the requirements of GB / t9439-2010 lost foam casting gray iron castings, it is used in the test Φ 30mm single cast test bar. See Fig. 1 for the shape, size and spacing of test bar. See Fig. 2 for the shape and processing size of tensile test bar. The EPS foam board is used in the EPC pattern and is cut by automatic numerical control foam cutting machine. The pattern is dipped and coated for 3 times with a Baume degree of 1.6 ~ 1.8. After dipping the coating each time, it shall be dried in a drying room at 45 ± 5 ℃ for 12h, and the thickness of the coating layer shall be controlled at 1.2 ~ 1.5mm. The pattern of EPC test bar and the pattern of EPC gray iron castings are put into the side extraction sand box, which adopts 20 / 40 mesh Baozhu sand dry sand and can be molded and boxed on a variable frequency three-dimensional shaking table.

2. Melting and pouring

(1) The smelting takes Q235 scrap as the main raw material, selects graphite type carburizing agent to adjust the C content, and uses ferrosilicon and ferromanganese to adjust the Si and Mn content in molten iron. Chemical composition of HT200 EPC gray cast iron and HT250 inoculated cast iron.

(2) casting the same ladle of molten iron by using clay sand mold and lost foam casting to pour two kinds of test bars. As the lost foam casting process consumes a lot of heat when the foam pattern is vaporized, the gas and carbon slag can be discharged smoothly without any residue in the sample, and the pouring temperature is controlled at 1480~1. 520 ℃, and the negative pressure during pouring shall be controlled at 0.03 ~ 0.04MPa. The pressure shall be relieved 5 ~ 8min after pouring, and the test bar shall be taken out after cooling for 1H.

3. Test method

The evaluation of microstructure of EPC gray cast iron is mainly based on GB / t7216-2009 standard, and the determination of mechanical properties is mainly based on GB / t9439-2010 standard. Wes-600b universal testing machine shall be used for tensile test, and the test requirements shall be in accordance with the provisions of GB / t228; Hbe-300a electronic Brinell hardness tester is used for hardness test. The test parameters are: the diameter of quenched steel ball is 10mm, the test load is 29.4kn and maintained for 10s; For metallographic structure observation, use xjp-6a metallographic microscope to check the graphite length in polished state, select three representative fields of view, and evaluate the graphite length grade according to the average value of the longest three graphite.