In order to ensure the smooth operation of the overall process of cast steel production, while taking into account the yield and effect of rare earth elements, Baotou Rare Earth Research Institute has proposed to use high-purity rare earth ferroalloy as an additive in 00Cr13Ni5Mo super martensitic stainless steel in recent years, and the yield of rare earth elements in steel is more than 40% (Table 1).

| Ingot number | 0# | 1# | 2# | 3# | 4# | 5# | 6# |

| Cerium content | 0 | 0.013 | 0.04 | 0.052 | 0.12 | 0.13 | 0.22 |

| Yield | / | 43.3 | 57.1 | 52.0 | 60.0 | 43.3 | 55.0 |

It can be seen from Figure 1 and table 2 that an appropriate amount of rare earth can play a good role in modifying the inclusions in cast steel. After adding rare earth, the inclusions in cast steel are mainly small, spherical rare earth sulfur oxide composite inclusions, which weakens the adverse effects of alumina and sulfide inclusions. However, when the rare earth is added in excess, the inclusion morphology in 6# cast steel will appear, the number of rare earth sulfur oxide composite inclusions will increase significantly, and the phenomenon of agglomeration and growth will occur, which will seriously affect the mechanical properties of cast steel.

| Ingot number | Ce | O | S | Al | Fe | C |

| 0# | / | 40.6 | / | 41.9 | 1.05 | 3.6 |

| 3# | 40.57 | 17.2 | 1.64 | 15.99 | 2.5 | 4.13 |

| 6# | 63.58 | 6.16 | 6.96 | 8.44 | 1.66 | 3.88 |

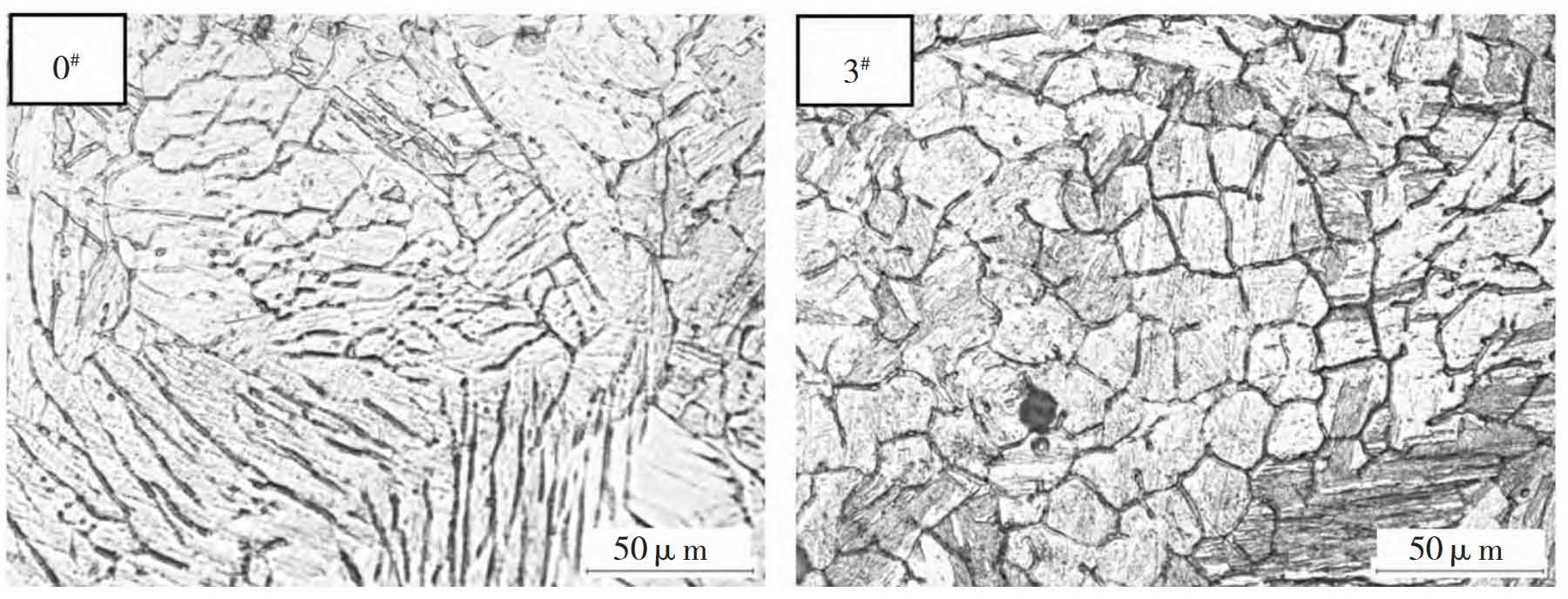

The effect of rare earth on the microstructure of cast steel is shown in Figure 2. It can be seen that when rare earth is not added, the grain morphology of cast steel is mainly in strip shape, knife edge shape and multilateral shape, with sharp edges, slender grains and large size; After adding rare earth, the grain morphology of cast steel is mainly cobblestone, the edge is relatively smooth, and the size is significantly reduced, indicating that rare earth can refine the grain of cast steel, which will help to improve the mechanical properties of cast steel, such as strength and plasticity.

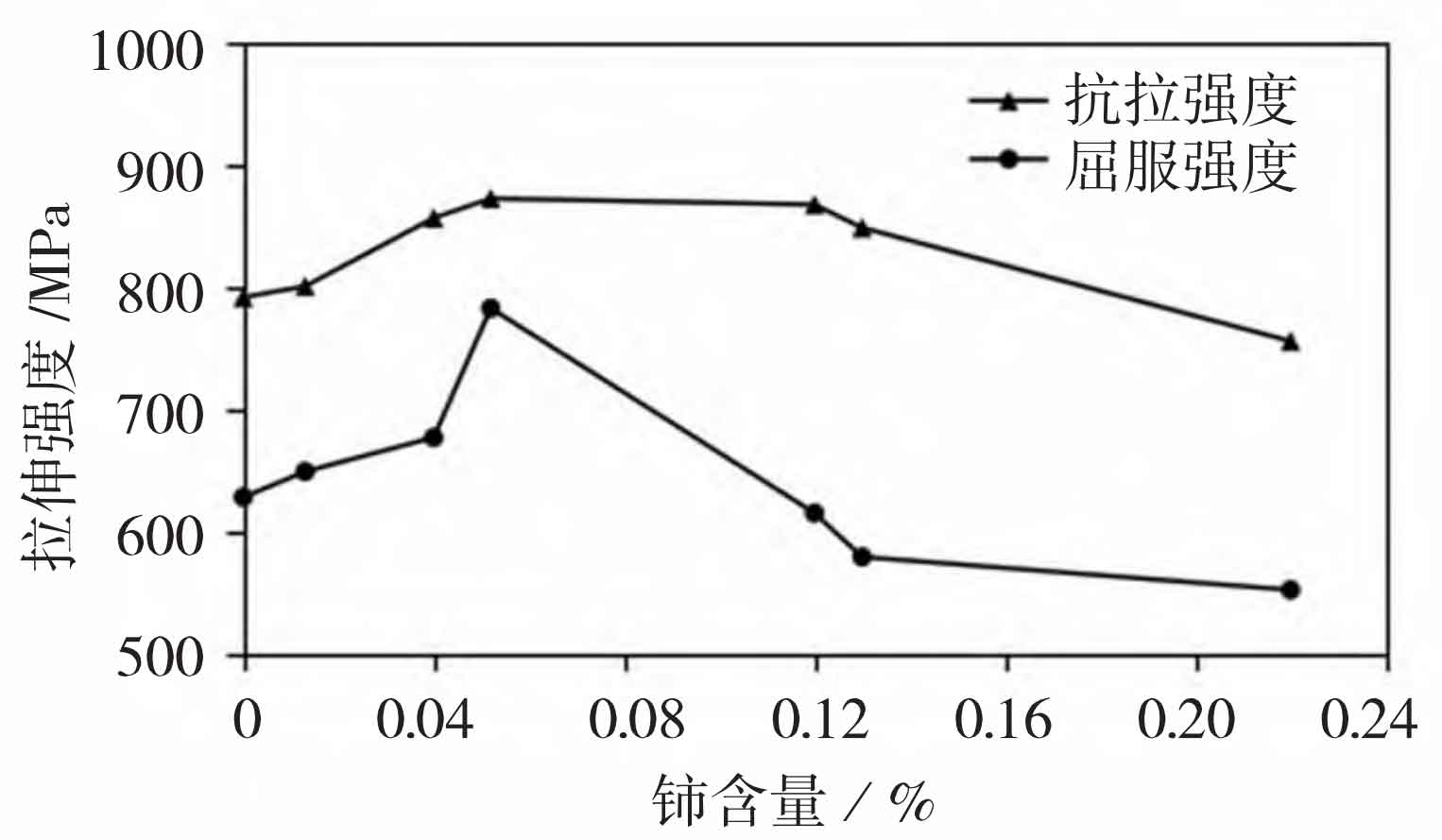

The tensile test results of cast steel with different rare earth cerium content are shown in Figure 3. The results show that with the increase of rare earth cerium content, the tensile strength and yield strength of cast steel first increase and then decrease. When the cerium content is 0.052%, the tensile strength and yield strength of cast steel show a peak. After adding rare earth cerium, the tensile strength and yield strength of cast steel are increased by 10% and 25%, which is because rare earth cerium can refine the grain of cast steel, and then improve the tensile strength and yield strength of cast steel; At the same time, rare earth cerium has the effect of modifying the inclusions in cast steel, forming fine spherical and dispersed rare earth sulfur oxide composite inclusions, which can resist the formation and propagation of cracks in the process of external force, and further improve the tensile properties of cast steel. However, when rare earth cerium is added in excess, the number and size of inclusions will increase significantly, but the tensile strength and yield strength of cast steel will be reduced.

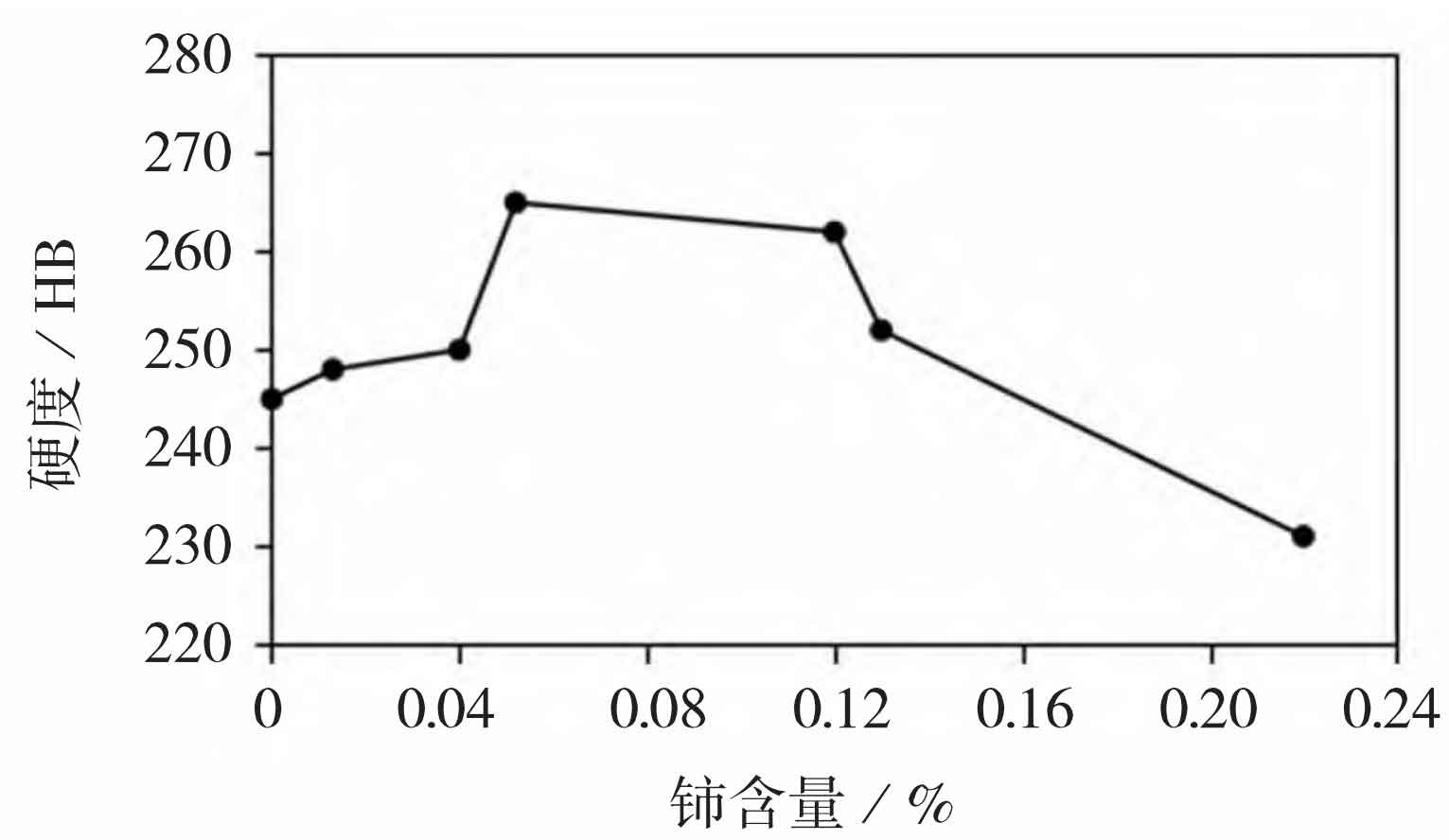

Figure 4 shows the change trend of hardness of cast steel with rare earth cerium content. It can be seen that with the increase of cerium content, the hardness of 1#, 2# cast steel slowly increases; When the cerium content increased from 0.04% to 0.052%, the hardness of cast steel increased significantly and peaked, which was 8% higher than that without rare earth; The cerium content continues to increase, and the hardness of cast steel decreases slowly; When the cerium content increases from 0.12% to 0.13%, the hardness of cast steel decreases rapidly. Because rare earth cerium can refine the grain of cast steel, its structure is more fine and uniform, and the strength is also improved while improving the toughness; However, with the further increase of rare earth cerium, the hardness of cast steel began to decline, indicating that the increase of Rare Earth Cerium on the hardness of cast steel is also limited. Excessive rare earth cerium will even lead to the trend of grain enlargement. Therefore, it is necessary to control the amount of rare earth cerium within an appropriate range.

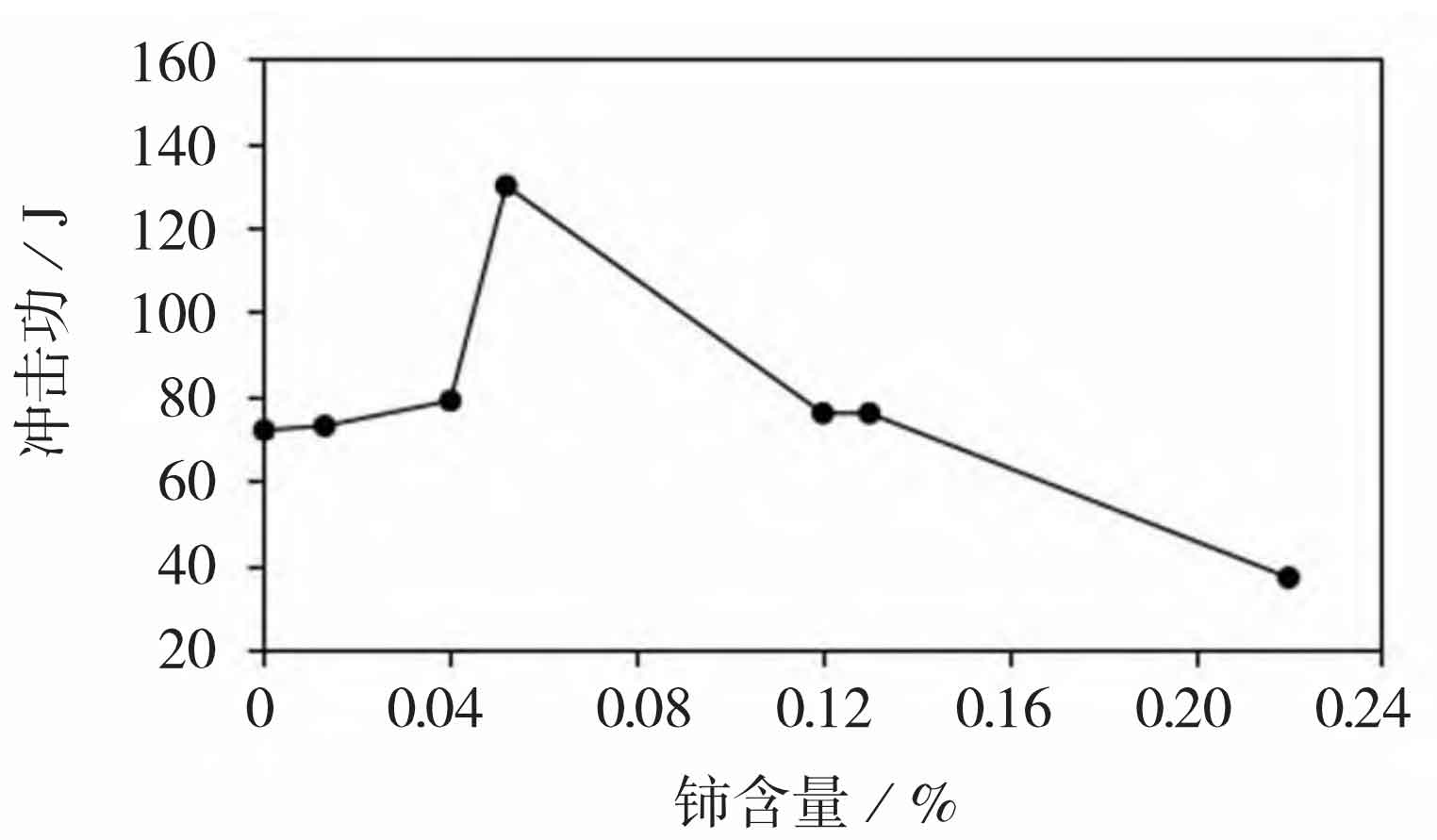

Figure 5 shows the change trend of impact energy of cast steel with rare earth cerium content. The results show that with the increase of cerium content, the impact energy of cast steel increases slowly at the beginning; When the cerium content increases from 0.04% to 0.052%, the impact energy of cast steel increases significantly and reaches a peak value; With the continuous increase of cerium content, the impact energy of cast steel decreases. After adding rare earth cerium, the impact energy of cast steel increases from 72j to 130j, which is increased by 81%. The impact properties of cast steel are significantly improved after adding rare earth element cerium, which is due to the role of rare earth cerium in modifying inclusions. The small spherical rare earth sulfur oxide composite inclusions can effectively alleviate the stress concentration and resist the formation and propagation of cracks; Rare earth cerium can refine the grain size and purify the grain boundary of cast steel at the same time, which improves the toughness of cast steel. However, adding too much rare earth cerium will increase the number and size of inclusions, hinder the movement of dislocations, cause dislocation stacking, and on the contrary, reduce the impact properties of cast steel.

In a word, the addition of rare earth ferroalloy in cast steel can modify inclusions and refine grains, and the mechanical properties of cast steel can be improved, but it is necessary to find out the optimal amount of rare earth.