Casting shrinkage is an inherent phenomenon in foundry processes that poses significant challenges to the production of high-quality castings. Understanding the role of casting shrinkage and implementing effective solutions are crucial for ensuring dimensional accuracy, structural integrity, and overall casting quality. This article explores the role of casting shrinkage in foundry processes, the challenges it presents, and the solutions employed to overcome them.

- Fundamentals of Casting Shrinkage: Gain a comprehensive understanding of casting shrinkage, including its causes and mechanisms. Explore how the solidification process and phase changes during cooling contribute to the contraction and volume reduction of molten metal, leading to shrinkage defects.

- Challenges Associated with Casting Shrinkage: Identify the challenges posed by casting shrinkage in foundry processes. These challenges may include dimensional inaccuracies, shrinkage porosity, microporosity, and overall reduction in casting quality. Learn about the impact of shrinkage defects on the mechanical properties, machinability, and performance of castings.

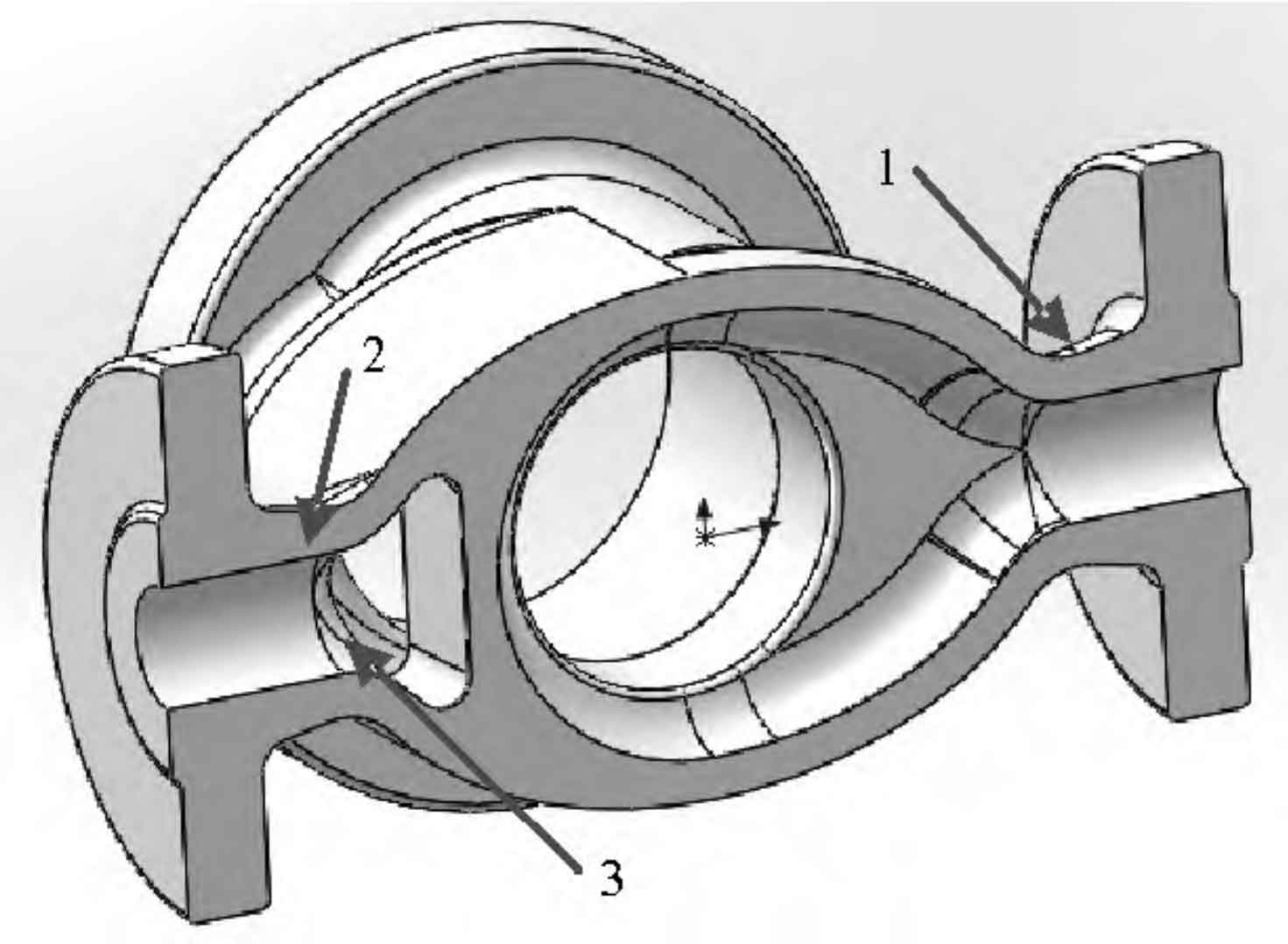

- Process Control and Optimization: Discover the importance of process control and optimization in mitigating casting shrinkage. Explore strategies such as proper gating and riser design, optimized pouring and solidification parameters, and controlled cooling rates to ensure adequate feeding and compensate for shrinkage. Learn about the use of advanced simulation tools to optimize casting parameters and minimize shrinkage defects.

- Pattern and Mold Design Considerations: Understand the role of pattern and mold design in minimizing casting shrinkage. Explore the importance of proper parting line placement, draft angles, and fillets to reduce stress concentrations and promote uniform solidification. Learn about the selection of appropriate mold materials and coatings to minimize mold-related shrinkage defects.

- Alloy Selection and Modification: Discover how alloy selection and modification can influence casting shrinkage. Explore the role of alloy composition, grain refinement techniques, and inoculation in controlling solidification behavior and minimizing shrinkage defects. Understand the impact of alloy properties on the susceptibility to shrinkage and the importance of alloy testing and quality control.

- Quality Assurance and Inspection: Learn about the significance of quality assurance measures and inspection techniques in detecting and addressing casting shrinkage defects. Explore the use of non-destructive testing methods, such as radiographic inspection, ultrasonic testing, and visual inspection, to identify shrinkage porosity and ensure casting integrity.

By recognizing the role of casting shrinkage in foundry processes and implementing effective solutions, foundry professionals can overcome the challenges associated with shrinkage defects and enhance the quality of castings. Through process optimization, proper pattern and mold design, alloy selection, and rigorous quality control measures, the detrimental effects of casting shrinkage can be minimized, resulting in dimensionally accurate, structurally sound, and high-quality castings.