Steel casting has long been a cornerstone in the automotive industry, providing essential components that contribute to the durability, safety, and performance of vehicles. With the automotive sector continuously evolving, the role of steel casting is also undergoing significant changes. This article explores current trends in steel casting within the automotive industry and examines future prospects, supported by tables and lists for better comprehension.

Introduction

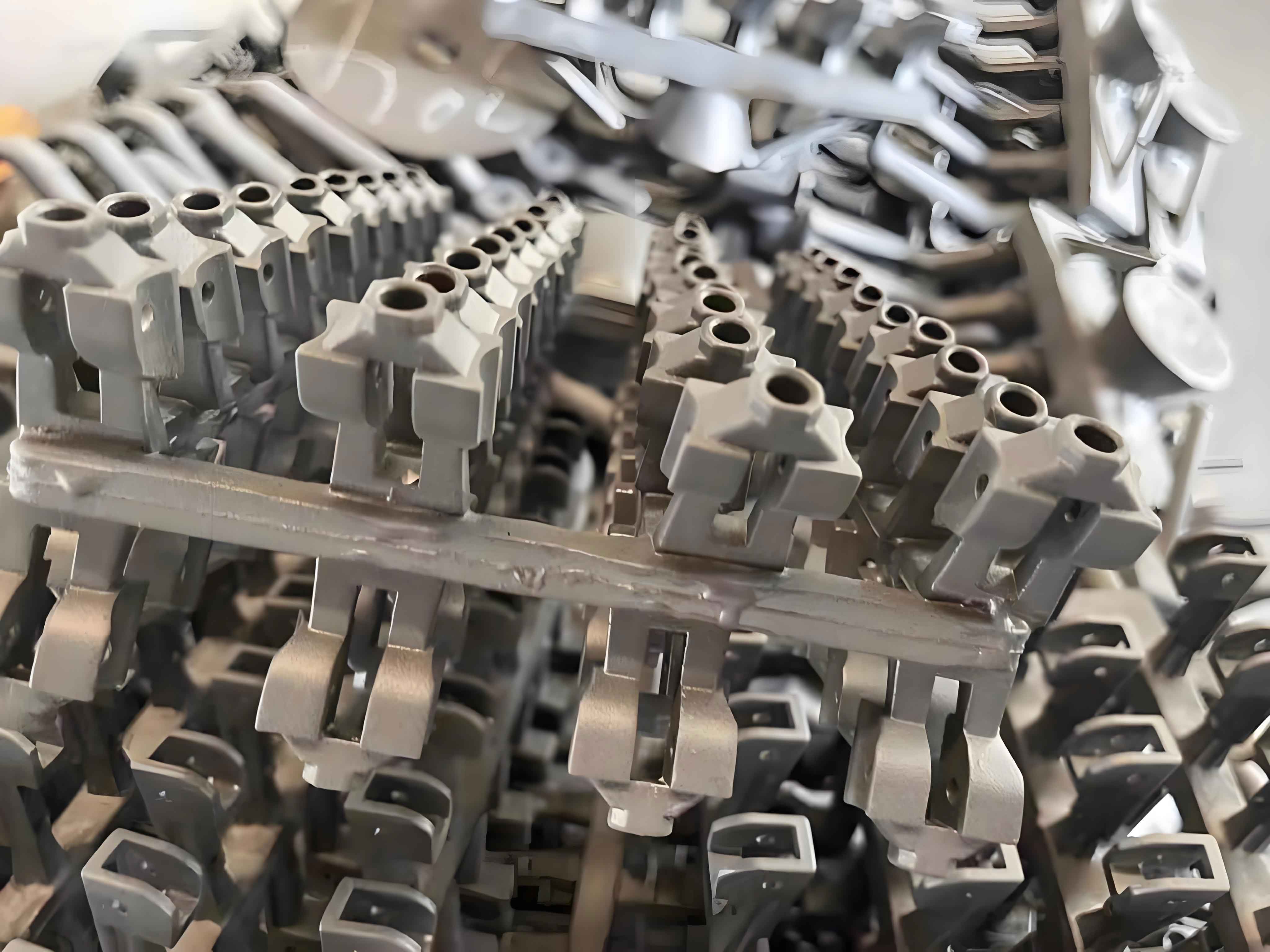

Steel casting is a manufacturing process where molten steel is poured into molds to create parts with complex geometries and high mechanical strength. In the automotive industry, steel casting is used to produce critical components such as engine blocks, suspension parts, and transmission housings. This process is valued for its ability to produce high-strength components with intricate designs, essential for modern vehicle performance and safety.

Current Trends in Steel Casting for Automotive Applications

- Lightweighting:

- The automotive industry is increasingly focused on reducing vehicle weight to improve fuel efficiency and reduce emissions. Advanced high-strength steels (AHSS) and optimized casting techniques are being developed to produce lighter yet stronger components.

- Advanced Manufacturing Techniques:

- Techniques such as precision casting, vacuum casting, and 3D sand printing are being adopted to improve the accuracy and quality of cast steel components, leading to enhanced performance and reduced waste.

- Enhanced Material Properties:

- Innovations in alloy compositions and heat treatment processes are enhancing the mechanical properties of steel casting, resulting in parts that are more resistant to wear, fatigue, and corrosion.

- Sustainability:

- There is a growing emphasis on sustainable manufacturing practices, including the use of recycled materials, energy-efficient processes, and reducing carbon footprints associated with steel casting.

Table: Key Trends in Steel Casting for Automotive Industry

| Trend | Description | Impact on Automotive Industry |

|---|---|---|

| Lightweighting | Development of lighter, stronger steel components | Improved fuel efficiency, reduced emissions |

| Advanced Manufacturing Techniques | Adoption of precision and vacuum casting methods | Enhanced component accuracy and quality |

| Enhanced Material Properties | Innovations in alloy composition and heat treatment | Increased durability and performance of components |

| Sustainability | Focus on recycled materials and energy-efficient processes | Reduced environmental impact and cost savings |

Applications of Steel Casting in Automotive Industry

- Engine Components:

- Steel casting is used to manufacture engine blocks, cylinder heads, and manifolds. These components require high strength and thermal stability.

- Suspension and Steering Parts:

- Control arms, knuckles, and other suspension parts are often made from steel casting due to their need for strength and durability under varying loads.

- Transmission and Drivetrain:

- Components such as gearbox housings, differential cases, and axles benefit from the robust properties of steel casting.

- Safety-Critical Components:

- Steel casting is used in parts like brake calipers and steering knuckles, where safety and reliability are paramount.

List: Benefits of Steel Casting in Automotive Manufacturing

- High Strength-to-Weight Ratio:

- Steel casting provide a superior balance of strength and weight, essential for modern automotive design.

- Design Flexibility:

- The steel casting process allows for complex shapes and geometries that are difficult to achieve with other manufacturing methods.

- Cost-Effectiveness:

- Steel casting is a cost-effective method for producing large volumes of parts with consistent quality.

- Material Versatility:

- A wide range of steel alloys can be used in steel casting to achieve specific mechanical properties tailored to different automotive applications.

Future Prospects of Steel Casting in Automotive Industry

- Integration with Additive Manufacturing:

- Combining traditional casting with additive manufacturing techniques (such as 3D printing) can lead to innovative component designs and improved material properties.

- Development of New Alloys:

- Research into new steel alloys with superior performance characteristics, such as improved high-temperature stability and corrosion resistance, will continue to advance.

- Automation and Smart Manufacturing:

- The implementation of Industry 4.0 technologies, including automation, robotics, and IoT, will enhance the efficiency and precision of steel casting processes.

- Increased Recycling and Sustainability:

- Future advancements will likely focus on increasing the use of recycled materials and further reducing the environmental impact of steel casting.

Table: Future Prospects for Steel Casting in Automotive Industry

| Prospect | Potential Benefits | Expected Industry Impact |

|---|---|---|

| Integration with Additive Manufacturing | Innovative designs, enhanced properties | More efficient and creative component production |

| Development of New Alloys | Superior performance characteristics | Improved durability and functionality of automotive parts |

| Automation and Smart Manufacturing | Enhanced efficiency and precision | Reduced production costs, higher quality control |

| Increased Recycling and Sustainability | Greater use of recycled materials, lower environmental impact | Eco-friendly manufacturing practices, cost savings |

Conclusion

Steel casting remains a vital process in the automotive industry, continuously adapting to meet the demands of modern vehicle manufacturing. Current trends emphasize lightweighting, advanced manufacturing techniques, enhanced material properties, and sustainability. Looking ahead, the integration of additive manufacturing, development of new alloys, automation, and increased recycling promise to further elevate the role of steel casting. By embracing these innovations, the automotive industry can achieve greater efficiency, performance, and sustainability in the production of steel cast components.