Steel casting is a widely used manufacturing process that offers numerous advantages in terms of strength, durability, and versatility. This article delves into the applications and advantages of steel casting, highlighting why it is a preferred choice in various industries.

- Automotive Industry: Steel casting plays a vital role in the automotive industry, where components such as engine blocks, transmission parts, and suspension components require exceptional strength and durability. The ability to produce complex shapes and achieve high precision makes steel casting an ideal choice for automotive applications.

- Construction and Infrastructure: Steel casting is extensively used in the construction sector for the production of structural components like columns, beams, and connectors. Its high load-bearing capacity, corrosion resistance, and dimensional stability make it suitable for demanding infrastructure projects.

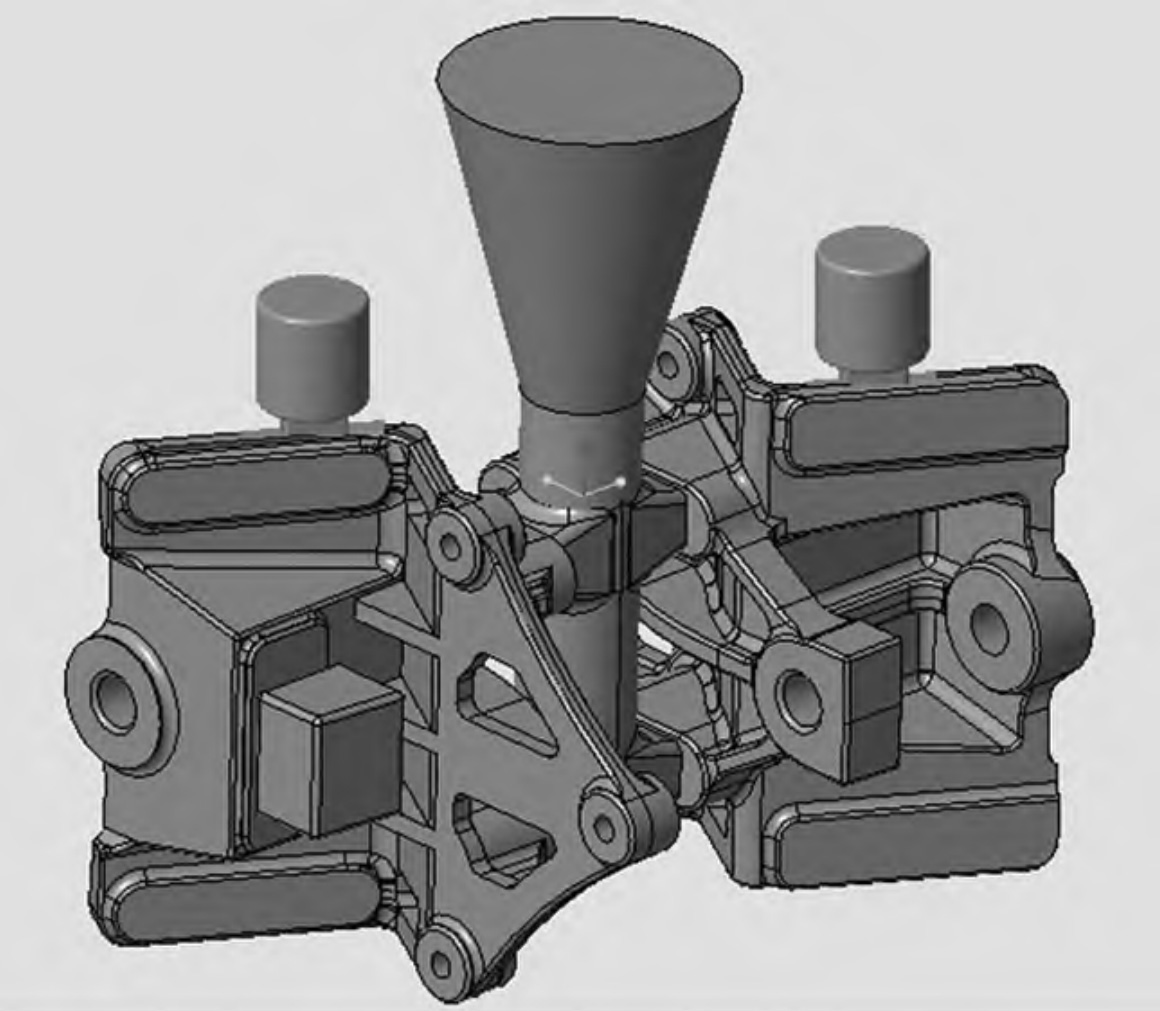

- Heavy Machinery and Equipment: Steel casting is crucial in the manufacturing of heavy machinery and equipment used in industries such as mining, agriculture, and material handling. Components like gears, pulleys, and hydraulic cylinders require the strength and toughness that steel casting provides.

- Oil and Gas Industry: Steel casting finds significant use in the oil and gas industry for critical components like valves, pumps, and drilling equipment. The ability to withstand extreme operating conditions, high pressures, and corrosive environments makes steel casting an optimal choice.

- Power Generation: Steel casting is essential for power generation applications, including turbines, generator components, and turbine casings. The high temperature and pressure resistance of steel make it ideal for these demanding environments.

Advantages of Steel Casting:

- Strength and Durability: Steel casting offers exceptional strength, toughness, and wear resistance, ensuring long-lasting performance even under extreme conditions.

- Versatility: Steel casting allows for the production of complex and intricate shapes, enabling designers to create components with precise dimensions and intricate details.

- Wide Material Selection: Steel casting offers a wide range of material options, including carbon steel, alloy steel, and stainless steel, allowing for the selection of specific grades tailored to the application requirements.

- Cost-Effectiveness: Steel casting can be a cost-effective solution compared to other manufacturing processes, especially for producing large and heavy components.

- Consistency and Reliability: Steel casting processes, such as investment casting and sand casting, provide excellent repeatability and consistency in producing high-quality components.

- Machinability: Steel castings are machinable, allowing for further processing and customization as per specific design requirements.

Understanding the applications and advantages of steel casting highlights its significance in various industries. The strength, durability, versatility, and cost-effectiveness of steel casting make it a preferred choice for critical components in automotive, construction, heavy machinery, oil and gas, power generation, and other sectors.