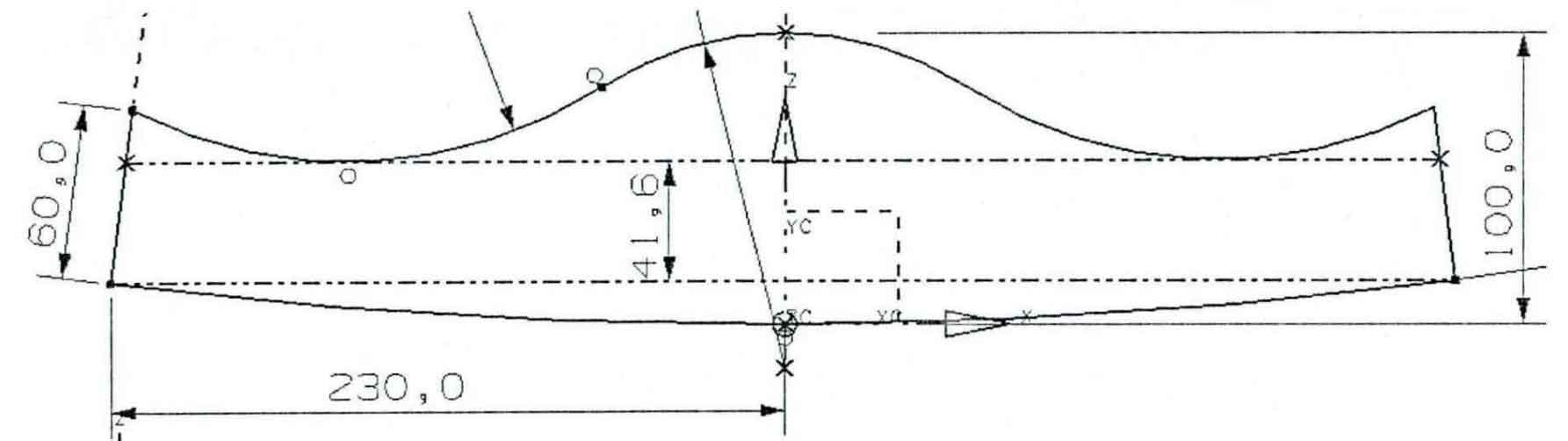

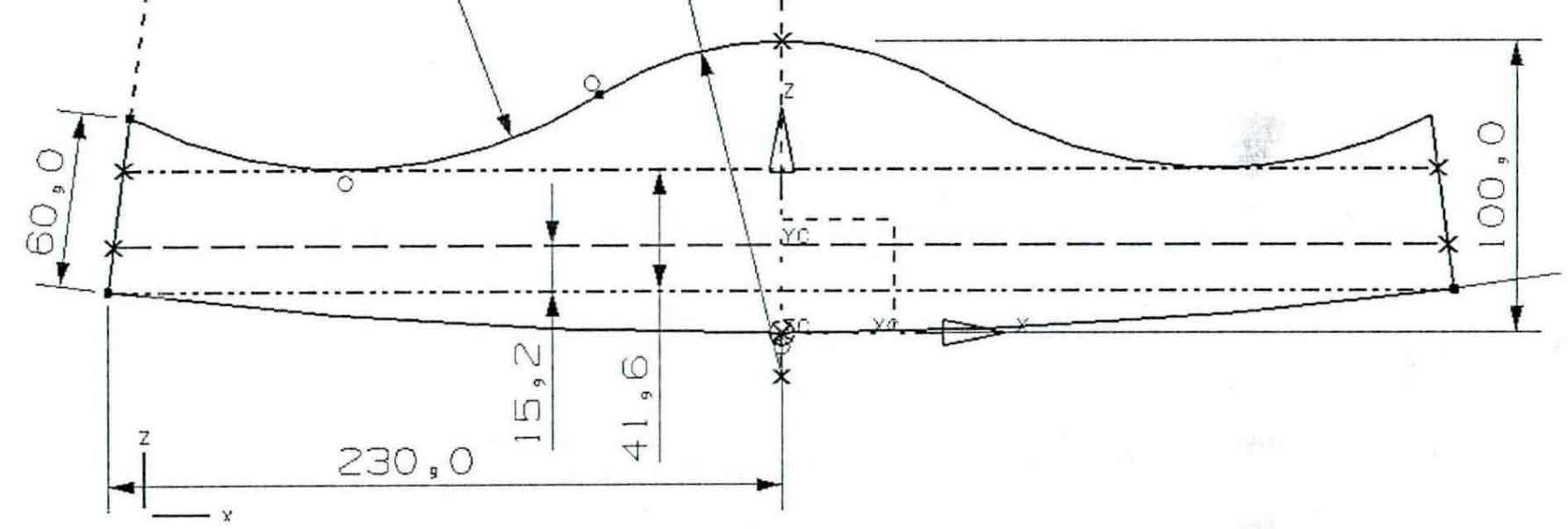

The composite thickness range of high chromium cast iron and carbon steel is shown in the figure below:

According to the failure and scrap position of the existing single metal casting liner, it is determined that the composite position of the composite interface is at the lower limit of the carbon steel layer thickness.

Similar to the traditional sand mold casting, the primary task of lost foam casting gating system design is to determine the size of ingate, and then calculate the size of sprue and runner in proportion. There are two common calculation methods:

Empirical method. Taking the traditional sand mold casting process as a reference, after checking the table or calculating by empirical formula, make appropriate adjustment, and generally increase;

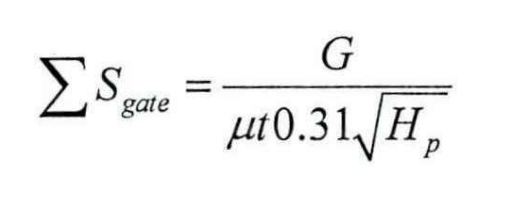

Theoretical calculation method. According to the hydraulic calculation formula:

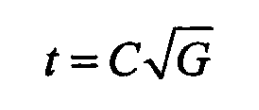

For carbon steel castings, the pouring time can be determined as follows:

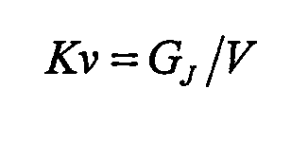

Determined by relative density kV of casting;

C. KV can be selected according to the following table:

| Kv | 0-1.0 | 1.1-2.0 | 2.1-3.0 | 3.1-4.0 | 4.1-5.0 | 5.1-6.0 |

| C | 0.8 | 0.9 | 1.1 | 1.2 | 1.3 | 1.4 |