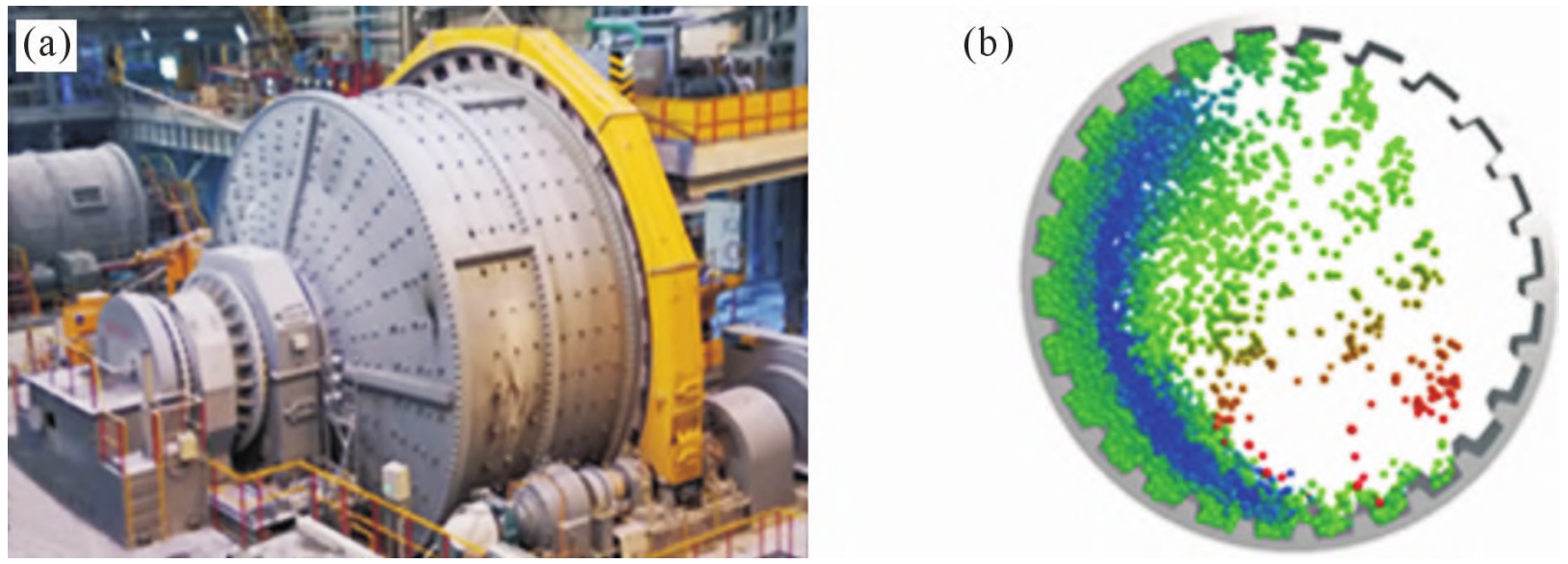

A grinder is a type of equipment that crushes and grinds various ores and other grindable materials into the cylinder to achieve the purpose of crushing materials. Since its inception in 1880, it has been equipped with high-strength bolts installed on the lining plate of the inner wall of the cylinder. On the one hand, it can protect the grinding cylinder from slurry erosion and direct impact of steel balls in black, non-ferrous metal mines, and non-metallic grinding for more than ten years; The other domain has been widely applied, as shown in Figure 1a. During the operation of the semi-automatic mill, the raised lifting strip on the lining plate can continuously lift the grinding medium and materials by the rotation of the cylinder, causing the processed material itself and the grinding medium (steel ball) to be lifted, and the material to be thrown and discharged to achieve crushing and grinding, as shown in Figure 1b.

The lining plate will be directly subjected to continuous and severe impacts from ore blocks and grinding media under working conditions, resulting in severe wear and tear, frequent fatigue wear and fracture damage, significantly shortened service life, and frequent disassembly, maintenance, and replacement. The mechanical properties of the lining plate will play a crucial role in the operational efficiency and efficiency of the semi mill, and its mechanical properties come from the casting material, ensuring the manufacturing process and improving the heat treatment process. Only by strictly controlling the quality from the source of its production, namely the V-method casting process, can its service life be guaranteed.

The lining plate of the semi-automatic mill cylinder adopts the V-method casting production process, with magnesium olivine sand as the molding sand and sodium silicate sand as the core sand. During casting production, it was found that there were large volume shrinkage and porosity defects at the lifting strip of the lining plate casting, which directly led to the generation of waste products. This study conducted a deep analysis of the causes of internal shrinkage and porosity defects in the lining plate of the semi-automatic mill cylinder produced by the V-method foundry. The independently developed “Intelligent Design of Casting Process (Cast Steel)” software was used to design a new casting process for the lining plate. The new casting process was then simulated and analyzed using ProCAST numerical simulation software. After simulation and production verification, the new casting process successfully eliminated the casting defects inside the lining plate castings.

1. Lining plate structure and material

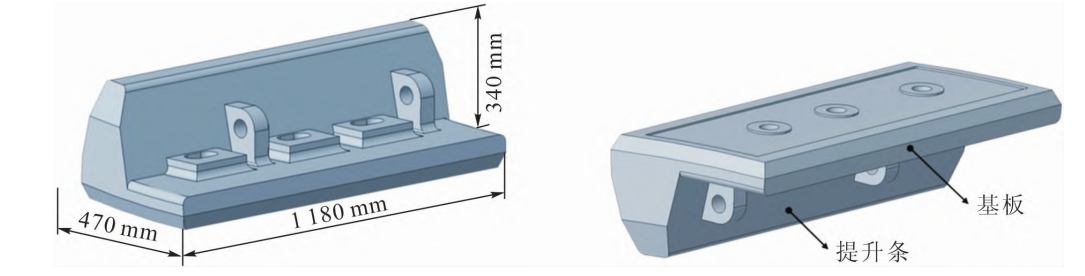

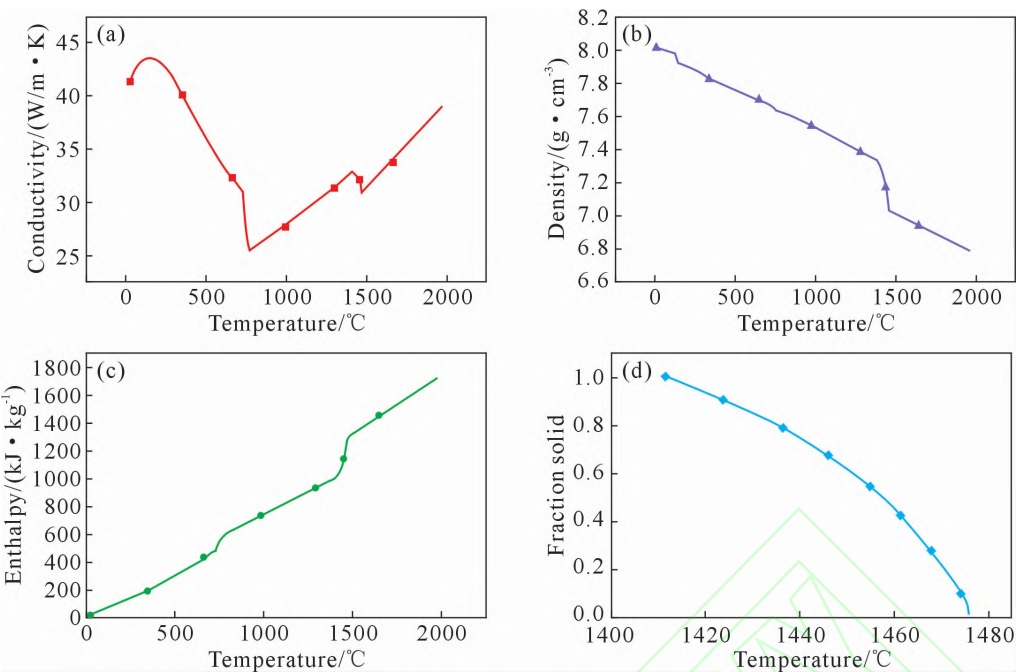

Figure 2 shows the contour dimensions of the semi-automatic mill cylinder liner produced by a V-process foundry, which are 1180mm x 470mm x 340 mm. The quality attributes are shown in Table 1. The surface of the lifting strip is the working surface of the lining plate, and the upper surface (curved surface) of the substrate is the installation surface of the lining plate. There are three through holes for installation inside. The material of the V-method casting for the lining plate is chromium molybdenum alloy steel, and its chemical composition is shown in Table 2. The liquidus temperature of alloy steel is 1476 ℃, and the solidus temperature is 1117 ℃. The other thermal properties of the alloy are shown in Figure 3. By using a medium frequency coreless induction furnace, the size waste and waste lining plates rolled by steel mills are melted into molten steel, and carbon content is adjusted by adding carburizing agents. The tapping temperature is about 1660 ℃. Before tilting the furnace for tapping, a mass fraction of 0.010%~0.015% rare earth silicon iron is added to the bottom of the ladle to melt it into the molten steel at high temperature for modification treatment.

2. Simulation analysis of V-method casting process for lining plate

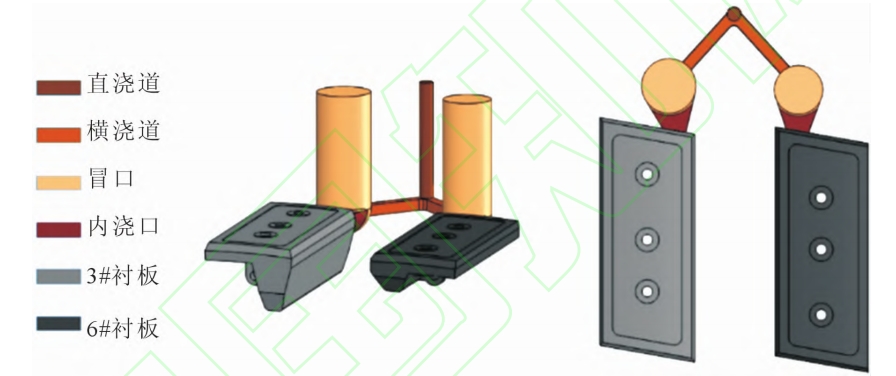

The V-method casting process for the lining plate is shown in Figure 4, with a production rate of 65.8%. The attracting position of the molten metal is at the end face of the lining plate casting, and the exposed riser is set between the casting and the inner runner, allowing the molten metal to flow into the mold cavity through the riser. The pouring temperature of the lining plate casting is 1530 ℃, and the external environmental temperature is 20 ℃. Due to the fact that the V-method casting uses dry sand compacted by negative pressure, which has a better insulation effect, the heat transfer coefficient between the metal liquid and the casting mold is set to 200 W · m K. The heat transfer coefficient between the mold and the external air cooling is set to 20 W · m.K. The inclined pouring is used, and the sand box pouring system end is raised upwards to form a 3.22 ° angle with the horizontal plane. This study only improves and analyzes the V-method casting process of the 3 # lining plate. The PrOCAST numerical simulation software was used to simulate and analyze the V-method casting process of the lining plate. The distribution of flow field, temperature field, solid content, and shrinkage porosity are shown in Figures 5-8, which only show the inner gate and casting.

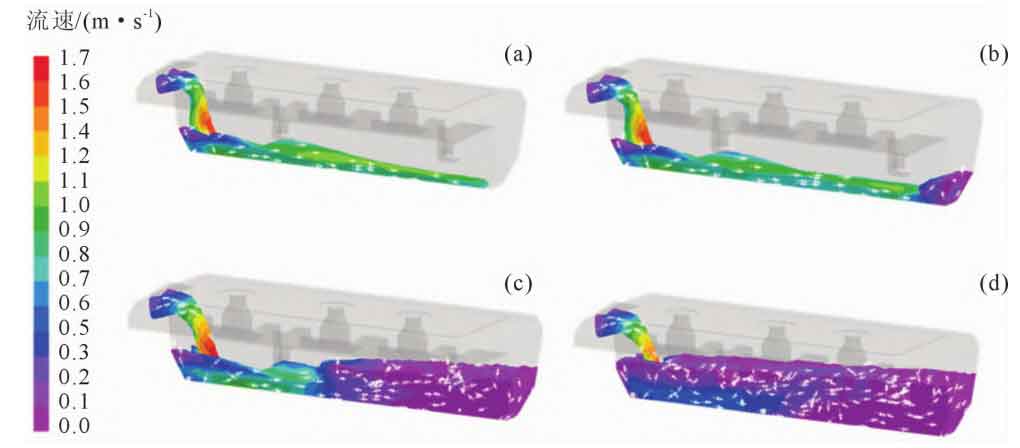

The metal liquid shown in Figure 5a quickly flows into the mold cavity through the inner gate. When the metal liquid approaches the end of the mold, it has the minimum potential energy and the maximum kinetic energy. Afterwards, the metal liquid collided with the end of the mold, causing significant changes in the magnitude and direction of its velocity vector, as shown in Figure 5b. At this point, due to strong erosion between the molten metal and the end wall of the mold, it is easy to cause the EVA film and coating layer responsible for maintaining the mold in a negative pressure state to fall off, thereby reducing the vacuum degree of the mold and potentially causing mold collapse. Subsequently, the metal liquid reflux generates turbulent pulsation, which easily leads to gas entrapment, as shown in Figure 5c. When the refluxed metal liquid contacts the other end of the mold cavity, the free liquid surface of the metal liquid in the mold is parallel to the horizontal quotient, and the liquid surface steadily rises until the filling is completed, as shown in Figure 5d.

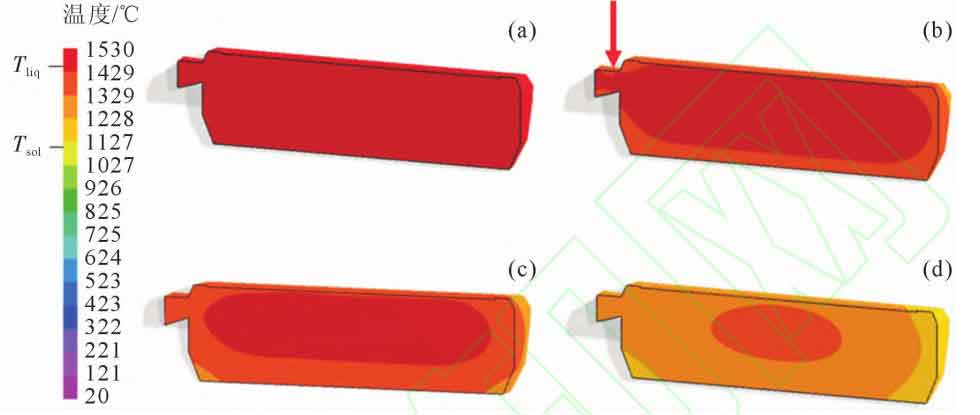

The temperature change during the solidification process of V-method castings is shown in Figure 6. At the end of 75 seconds of mold filling, the temperature at various parts of the lining plate is higher than the liquidus temperature. There is no cold shut in the V-method castings, resulting in insufficient pouring, as shown in the figure. With the increase of cooling time, the lining plate casting gradually solidifies from the outer edge to the thicker center, and the solid content increases accordingly, as shown in Figure 6b. When it solidifies to 2960 seconds, the shrinkage of the feeding channel of the lining plate casting narrows, and the solid content of the metal liquid at this point increases to 0.7%, as shown in Figure 7b. The feeding effect of the riser on the casting deteriorates. When cooled to 7 460s, the feeding channel will be blocked by the solidified metal, and the exposed riser will lose its feeding effect on the casting. An isolated liquid phase zone will form inside the village plate casting, as shown in Figure 6d. It is predicted that as the solidification process progresses, there is a tendency for shrinkage porosity and porosity to occur inside the casting. The center of the lining plate casting is the highest temperature part and also the position of the last solidification week. Based on this judgment, the safety position of the riser is unreasonable. Due to the blockage of the feeding channel, the riser prematurely lost its feeding effect on the casting. When the negative pressure sand box cools to 1.67×10’s, the temperature of each part of the lining plate casting is below 1107 ℃.

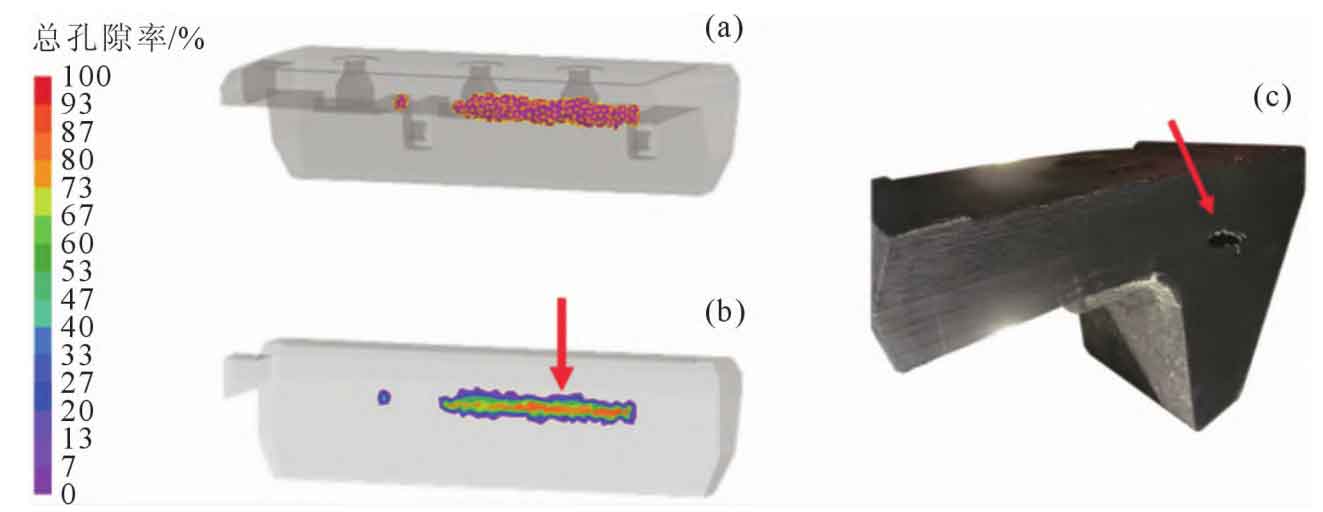

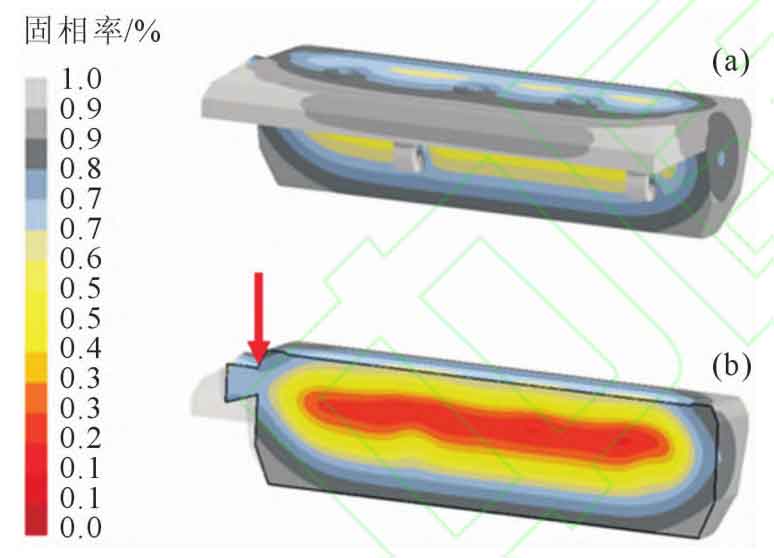

The highlighted yellow area in Figure 8a shows shrinkage porosity and shrinkage cavities with an internal porosity rate greater than 1% in the lining plate casting, with a volume of approximately 1155 cm. There are approximately 455 cm of pores in the shrinkage and shrinkage process, with a weighted average pore removal rate of approximately 28%. From Figure 8b, it can be seen that the porosity at the center of the lifting strip in the lining plate casting is severe, gradually evolving from dispersed shrinkage at the edges to concentrated shrinkage at the core. The distribution of shrinkage porosity and porosity obtained from the simulation of the V-method casting process for the lining plate is roughly consistent with the distribution of shrinkage porosity and porosity inside the lining plate castings produced by the V-method casting plant (Figure 8c). The shrinkage and porosity defects at the lifting strip of the casting will reduce the effective bearing area and generate stress concentration, resulting in a decrease in the mechanical properties and shortened service life of the casting.