The selection of negative pressure degree is particularly critical in vacuum negative pressure lost foam casting. A large number of documents and production practice have proved that properly increasing the negative pressure can effectively improve the dimensional deformation and box collapse defects of thin-walled gray cast iron gearbox shell casting in lost foam casting, reduce the slag inclusion casting defects and sand sticking defects of thin-walled gray cast iron gearbox shell casting in lost foam casting, shorten the pouring time of thin-walled gray cast iron gearbox shell casting in lost foam casting Reduce the risk of fire choking during pouring.

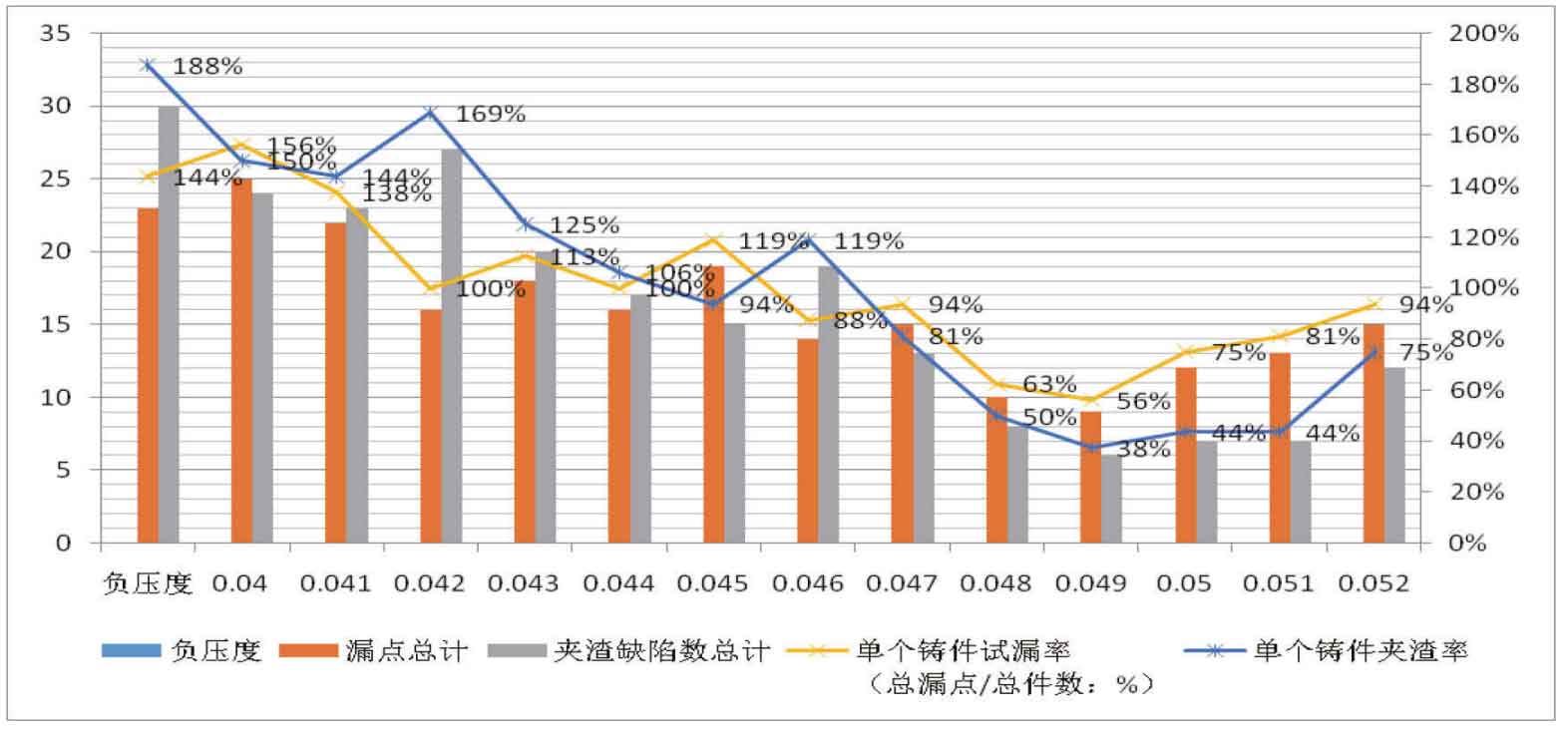

In order to find the appropriate negative pressure degree of this kind of thin-walled castings, lost foam casting thin-walled gray cast iron gearbox shell casting a is selected, and the improved gating system design scheme is adopted. The pouring temperature is set at 1470 ℃, and the negative pressure degree is gradually increased from 0.04 to 0.052 (each increase of 0.001 is a group, with two boxes in each group and 16 lost foam casting thin-walled gray cast iron gearbox shell castings), Verify the leakage qualification rate and slag inclusion defect rate of hydrostatic test, and the specific results are shown in the figure.

The results show that it is best to increase the negative pressure to 0.049. Improving the negative pressure alone has a certain effect on the defect improvement of the thin-walled gray cast iron gearbox shell cast by lost foam casting, but the qualified rate of leakage test and slag inclusion defect of the thin-walled gray cast iron gearbox shell cast by lost foam casting are still very high, which needs to be further optimized and improved from other aspects.