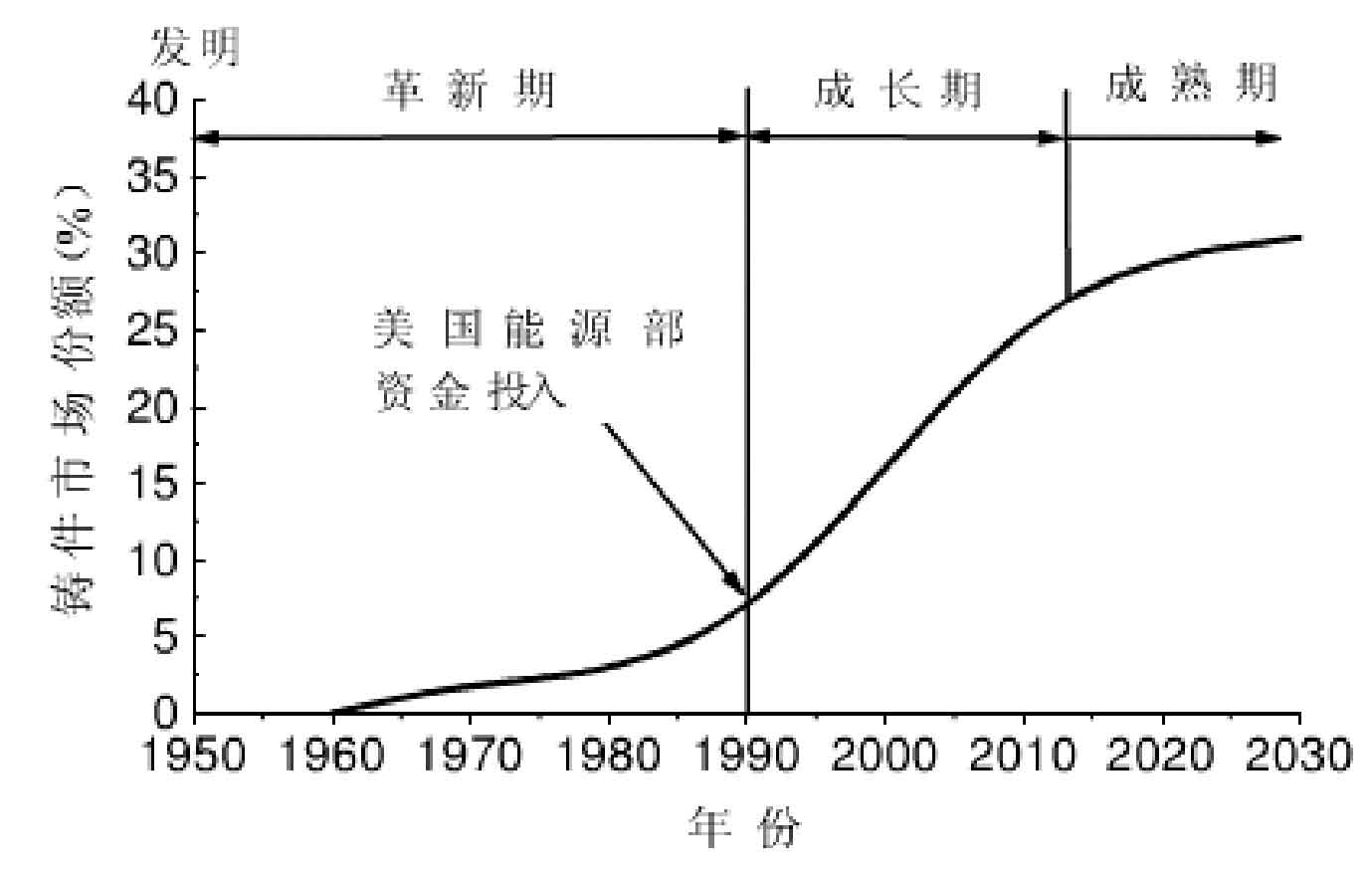

Auxiliary materials and aluminum alloy lost foam casting technology are the key research objects in the field of lost foam casting abroad at present, because foreign aluminum alloy materials are the main materials used in lost foam casting, such as some industrial developed countries, such as the United States, Japan, Germany and so on. According to foreign reports, we can know that in 2009, the lost foam casting in the United States was made of aluminum alloy, and its quantity was calculated in tons. As shown in the figure, the application trend of lost foam casting technology in the United States is shown. The market share of lost foam casting is also increasing year by year. It can be seen from the figure that it has entered a growth period since 1990 and is close to maturity in 2013. Its development speed is quite fast.

China’s research on aluminum alloy lost foam casting is still at its initial stage. Compared with the developed countries in Europe and America, China is lagging behind. It is still at a disadvantage whether in foam pattern materials or in the research of mold filling and solidification process. For aluminum alloy lost foam castings, the temperature control is relatively strict in the production process, which is determined by the characteristics of the material itself. The pouring temperature should not be too low or too high. Too low or too high temperature will cause defects. Because if the pouring temperature is too low, it will affect the fluidity of liquid metal, weaken its mold filling capacity, and may cause insufficient pouring and cold shut defects. If the pouring temperature is too high, it may cause shrinkage porosity and shrinkage defects, which is caused by serious suction phenomenon.