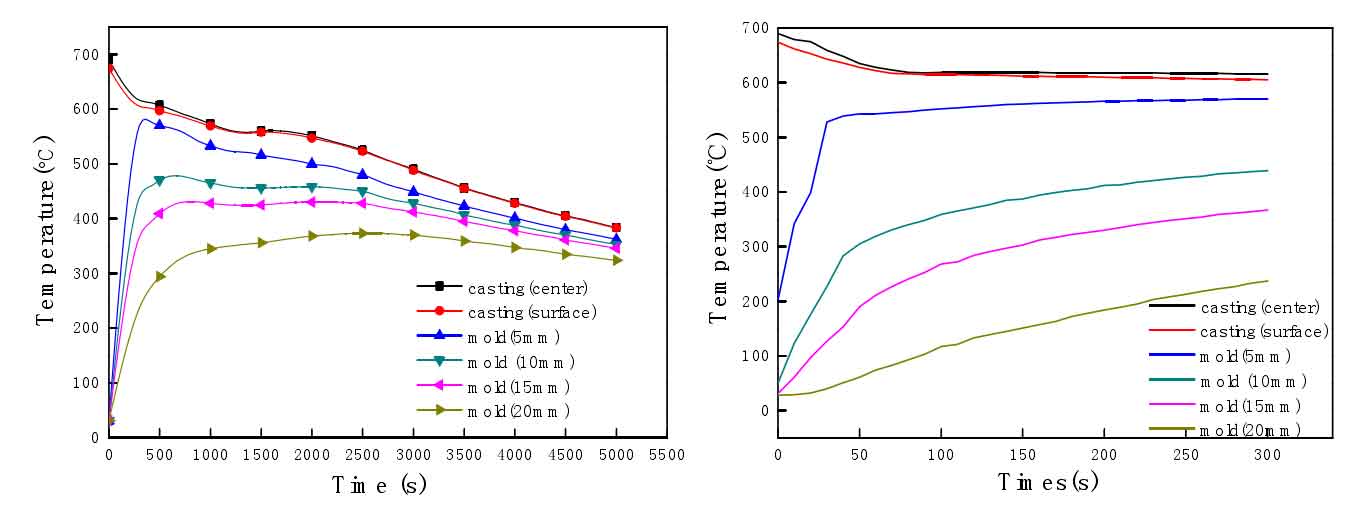

The temperature cooling curve of sand castings in phenolic urethane resin sand is shown in the figure. From figure (a), we can see the temperature trend of the whole sand mold casting and various points measured on the mold. The temperature of the surface and center of the sand casting decreases rapidly at the beginning, on the contrary, the temperature of the mold increases rapidly. As the temperature difference between the two approaches, the changes on both sides will be gentle. The specific temperature changes are as follows: the temperature in the center of the sand mold casting drops significantly from 690 ℃ to 635 ℃ in 0-60s. During the period of 60s to 300s, the temperature in the center of sand mold casting decreases relatively gently, and the temperature only decreases to 611 ℃. Then, the temperature decreased more slowly until 2300s, and the temperature of sand casting decreased below the solid phase line of 536 ℃.

It can be seen from figure (b) that in the range of 0-300s, the temperature of four points (tc2-tc5) in the mold at 5mm (TC2) from the heat exchange interface increases significantly from the beginning to 60s, up to 570 ℃, and then the temperature continues to rise, but the rising rate slows down. The temperature point 5mm away from the heat exchange interface reaches the maximum temperature of 571 ℃ at 300s. Then it began to cool down slowly, and finally at 5000S, the temperature reached 384 ℃. The temperature change trend at the three points 10mm (TC3), 15mm (TC4) and 20mm (TC5) away from the interface is roughly similar to that at Tc1. However, due to the heat dissipation distance, each point is relatively close at the last 5000S, which are 353 ℃, 346 ℃ and 326 ℃ respectively.