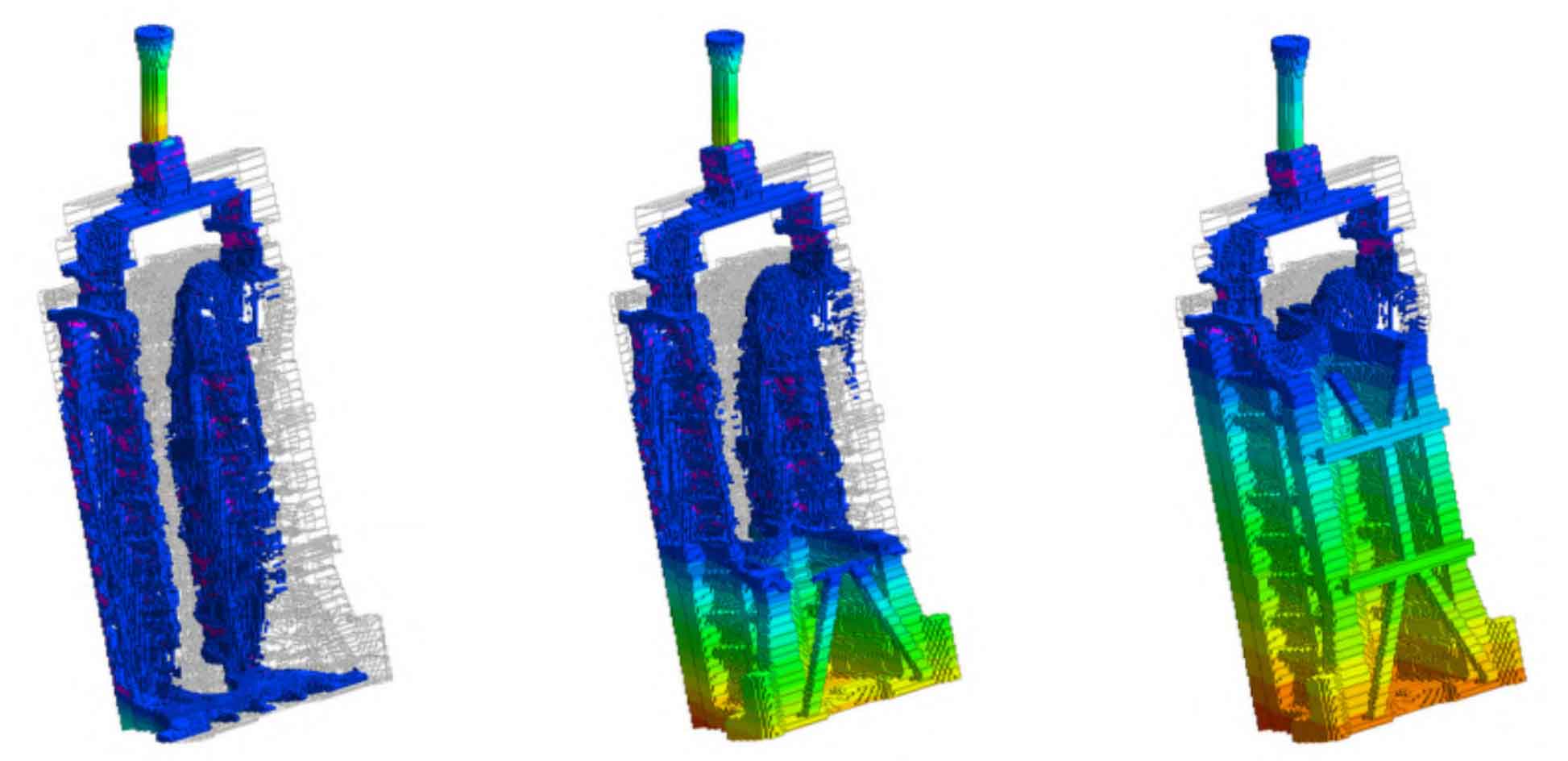

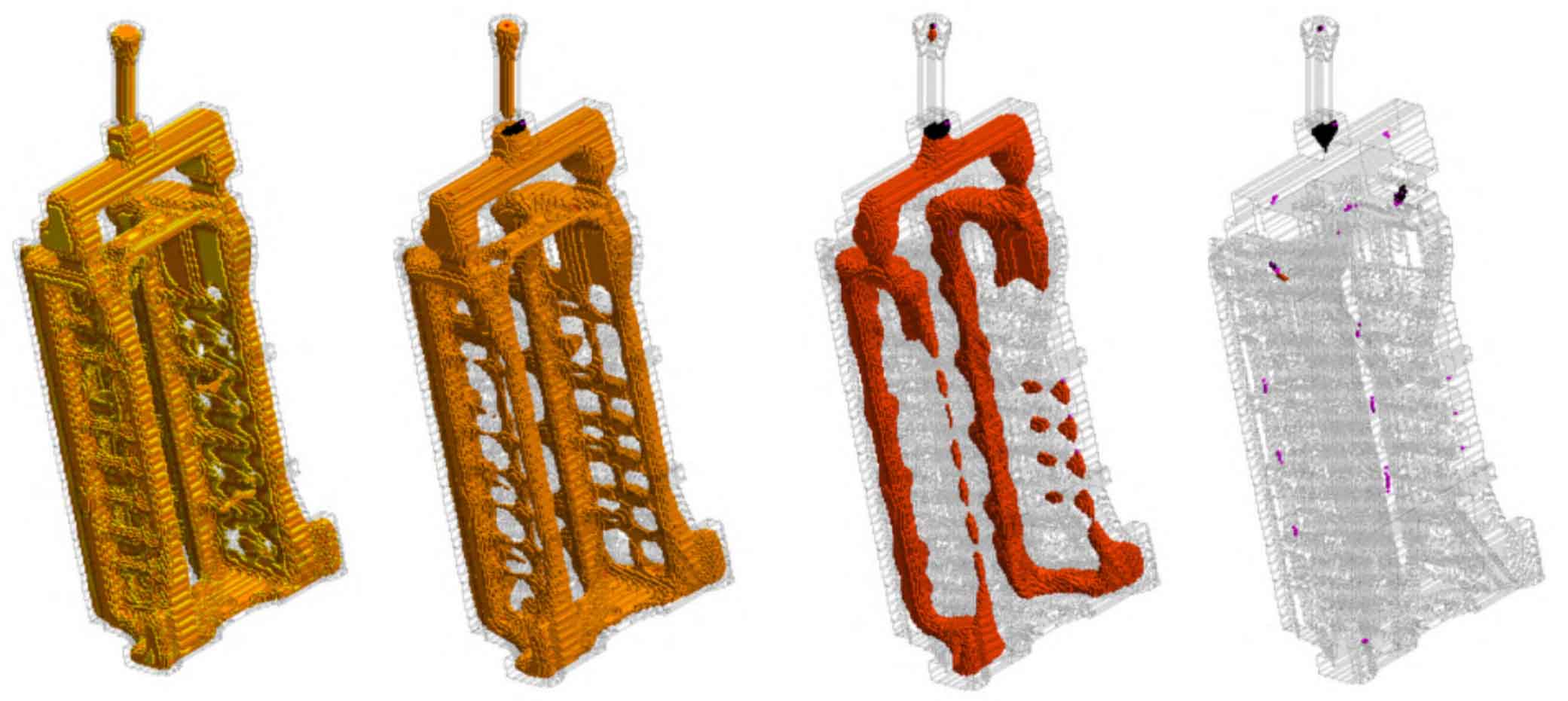

In order to verify whether the pouring process of A804T0-1009006 oil pan top-pouring inclined lost foam casting is reasonable, whether the molten iron filling can ensure smooth pouring, and whether the transverse runner can be used as a feeding riser to feed the thick hot spot at the top, the mold filling process and solidification process of molten iron are simulated, and the simulation results are shown in Figure 1 and Figure 2.

It can be seen from Figure 1 that the top-pouring process is used for pouring. The molten iron enters the cavity from the pouring system, falls into the bottom of the cavity, and then rises gradually from the bottom. The molten iron in the lower part gradually decreases with the filling process of molten iron, and the hot molten iron in the upper part supplements the solidification of the molten iron in the lower part. Finally, the solidification of the molten iron on the upper part of the nodular cast iron is supplemented by the hot molten iron in the pouring system, which realizes the orderly feeding of the molten iron and can eliminate the shrinkage defects at the drilling position of the nodular cast iron.

It can be seen from Figure 2 that there is no isolated liquid phase zone in a large area during the solidification process of the whole ductile iron casting. Only a small part of the liquid phase zone with a small volume can not get sufficient shrinkage during the solidification process. At the later stage of solidification, shrinkage defects may occur at this part. However, after pouring, the pressure holding time is longer (20 min), the negative pressure is 0.05 MPa, and the sand mold compactness is sufficient, so that this part of shrinkage porosity can supplement the molten iron during graphitization expansion.