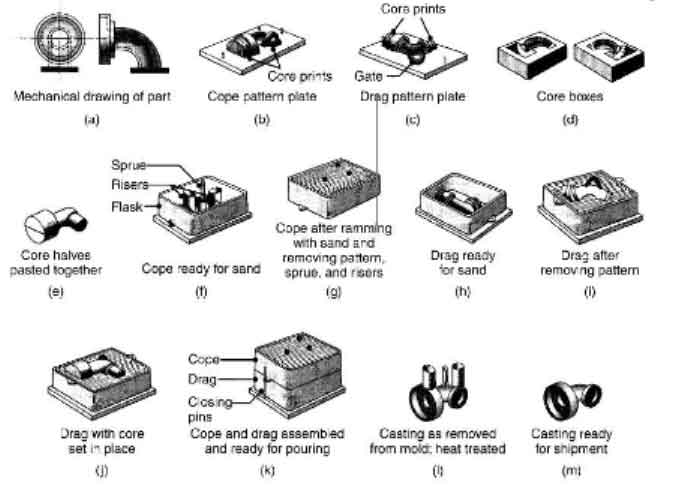

Creating sand casting parts involves a series of steps that start from designing the pattern and end with the finishing of the castings. Let’s unravel the process of creating sand casting parts:

1.Pattern Design:

The process begins with designing a pattern that represents the desired shape of the final casting. The pattern can be made from wood, plastic, or metal and should include allowances for shrinkage and machining.

2.Pattern Construction:

The pattern is constructed by skilled craftsmen using the design specifications. It is typically larger than the final casting to accommodate shrinkage during solidification.

3.Mold Preparation:

The pattern is mounted on a pattern plate, and a flask is placed around it to create the mold cavity. The flask consists of two parts: the cope (top half) and the drag (bottom half).

4.Mold Material:

The mold material is a mixture of sand and a binder. The sand used is usually silica sand, which is mixed with a binder like clay or resin to hold its shape. The mold material is prepared and conditioned to achieve the desired properties.

5.Mold Assembly:

The cope and drag halves of the flask are separated, and the pattern plate with the pattern is placed in the drag. Sand is then packed around the pattern, ensuring it is properly compacted and vented.

6.Core Preparation:

Cores may be required to create internal features of the casting. Cores are made from sand mixed with binders and are placed in the mold before closing it. Cores are typically made separately and are cured before being placed in the mold.

7.Mold Closing:

Once the sand is packed and the cores are in place, the cope is placed on top of the drag, aligning the two halves. The mold is securely closed, ensuring there are no gaps or misalignments.

8.Pouring System:

Channels called sprues, runners, and gates are created in the mold to allow the molten metal to flow into the mold cavity. These channels also help to remove gases and impurities from the mold.

9.Molten Metal Pouring:

The mold is prepared for pouring by ensuring it is dry and free from moisture. The molten metal, usually heated in a furnace, is poured into the sprue, and it flows through the runners and gates into the mold cavity.

10.Solidification:

After pouring, the molten metal cools and solidifies inside the mold. The cooling time depends on the size and complexity of the part, as well as the metal being used. Proper cooling and solidification are critical to achieving good casting quality.

11.Mold Breakout:

Once the metal has solidified, the mold is opened, and the casting is removed. The casting may have excess material like gates and risers, which are usually removed by cutting or grinding.

12.Finishing Operations:

The casting is cleaned, and any remaining mold material, called casting residue or sand, is removed through processes like sandblasting or shot blasting. The casting may undergo additional machining, grinding, or heat treatment processes to achieve the desired dimensions and surface finish.

13.Inspection and Quality Control:

The castings are inspected for defects such as porosity, cracks, and dimensional inaccuracies. Various non-destructive testing methods, such as visual inspection, X-ray, or ultrasonic testing, may be employed to ensure the quality of the castings.

14.Final Product:

After passing inspection, the sand casting part is considered complete and can be used for its intended application. It may require additional surface treatment, coating, or assembly before final use.

Throughout the process, it is important to maintain strict quality control measures, monitor process parameters, and make adjustments as necessary to ensure consistent and high-quality sand casting parts.