I. Introduction

The development of high-speed rail networks has become a driving force for national economic growth. With the continuous improvement of high-speed rail systems, higher requirements are imposed on the comfort, reliability, and safety of trains. As an important suspension component of high-speed trains, shock absorbers play a crucial role in ensuring the smooth operation of the train. The performance of shock absorbers directly affects the riding comfort and safety of passengers.

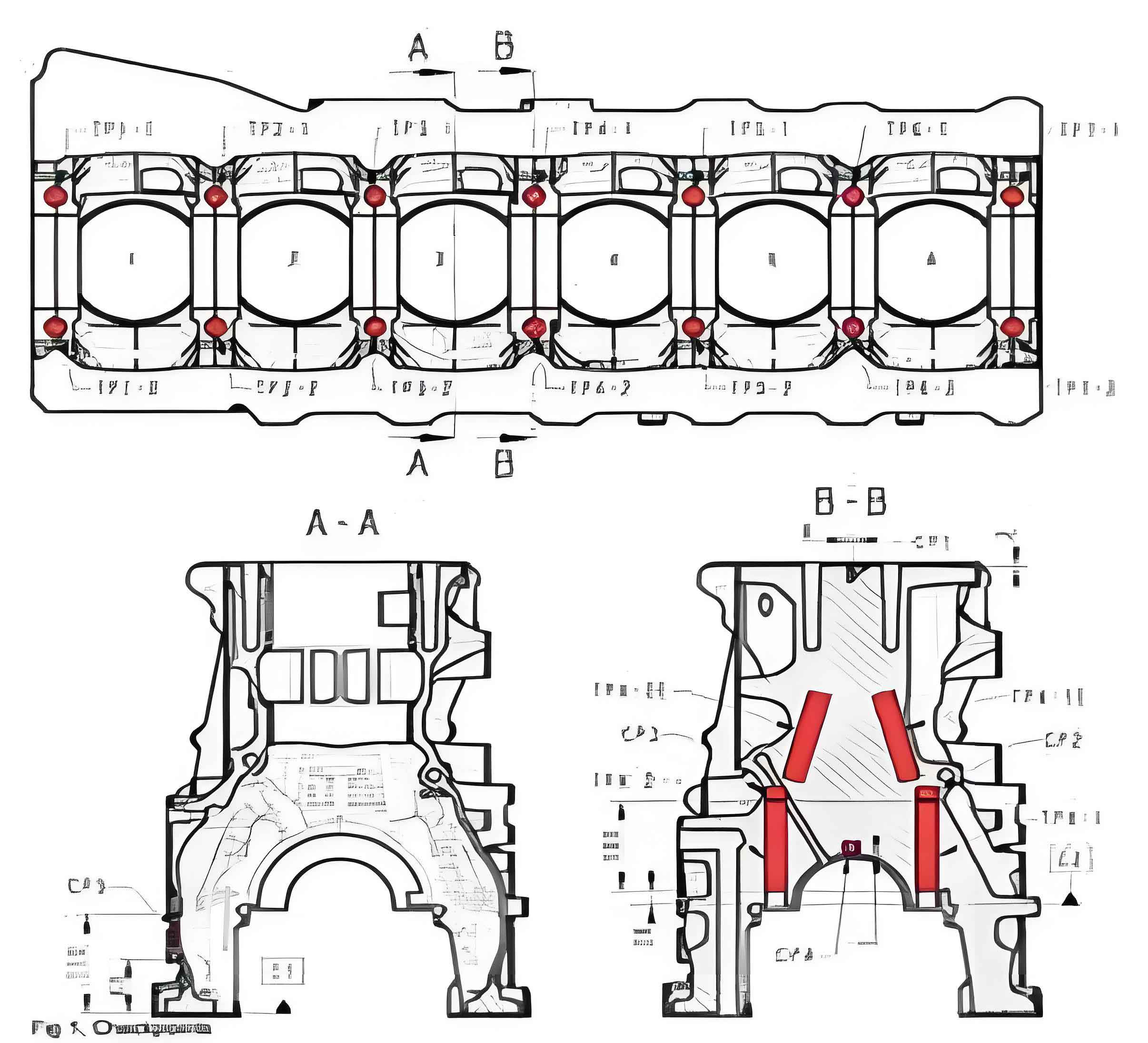

The ZG25MnCrNiMo high-speed rail shock absorption box is a key part of the high-speed rail shock absorber. It is subjected to complex forces during operation, including static and dynamic loads from the traction motor, as well as dynamic and static loads transmitted by the wheels and rails. Under the action of various alternating stresses, fatigue cracks may gradually occur. Therefore, improving the manufacturing technology of the ZG25MnCrNiMo high-speed rail shock absorption box is of great significance for enhancing the performance and service life of shock absorbers.

II. Current Situation of High-Speed Rail Shock Absorption Box Manufacturing Technology

A. Material Selection

In the past, the ZG230 – 450 ordinary carbon cast steel in the normalizing state was used for the high-speed rail shock absorption box. Later, in order to improve the strength and stiffness of the shock absorption box and increase its service life, low-alloy materials such as ZG16Mn, ZG25Mn, and ZG25MnCrNiMo were successively used. Currently, the domestic high-speed rail shock absorption box is mainly made of ZG25MnCrNiMo material.

B. Manufacturing Process and Quality Problems

The current domestic manufacturing process of high-speed rail shock absorption boxes mainly includes casting and machining. However, there are still some problems in the manufacturing process, such as low casting qualification rate and product yield. The casting qualification rate of lost foam casting is only about 50%, and the product yield is about 70%. In addition, only a few foundries can meet the mechanical property requirements of the standard. These problems not only increase the production cost but also affect the performance and service life of the shock absorption box.

III. Key Technologies of Lost Foam Casting for ZG25MnCrNiMo High-Speed Rail Shock Absorption Box

A. Grouping

- Finite Element Analysis and Process Optimization

Finite element analysis is carried out on the project product to establish a digital model. By observing the changes in the microstructure during the forming process, potential defects can be identified, and the casting process can be optimized. This helps to ensure the quality of the casting and improve the performance of the shock absorption box. - Pouring and Riser Setting

The hot spot position of the product is selected to calculate the size of the riser. According to the weight and structure of the product, the size and layout of the gating system are calculated to ensure that the product is formed completely during the pouring process without defects such as porosity, cracks, and slag inclusions.

B. Coating

- Coating Process and Material Selection

The coating process of the lost foam white mold includes multiple layers. The first and second layers use zircon powder + silica sol coating. Imported zircon powder with few impurities and uniform particles is selected to ensure the strength of the coating layer and avoid chemical reactions between the impurities in the zircon powder and ZG25MnCrNiMo, which may cause surface pits and affect the appearance quality. - Drying Process Control

During the drying process, the temperature and time of the drying room need to be strictly controlled. If the temperature is too high or the drying speed is too fast, the surface of the coating may crack, affecting the appearance and the difficulty of the subsequent cleaning process.

C. Melting and Pouring

- Melting Process

The melting process requires the use of an intermediate frequency induction furnace. The ratio of return materials and the charging sequence need to be controlled, as well as the tapping temperature of the molten steel. Deoxidation treatment is carried out on the molten steel to ensure the quality of the molten steel. - Pouring Process

The pouring process adopts the “slow – fast – slow” method, and the pouring time is controlled within 1 minute. The vacuum negative pressure is applied during pouring, and the negative pressure is maintained for 1 – 2 minutes. The tapping temperature of the molten steel is controlled at 1685 ± 10 °C, and the pouring temperature is controlled at 1610 – 1625 °C.

IV. Technical and Economic Index Comparison

| Items | Before Project Implementation | After Project Implementation |

|---|---|---|

| Product | Casting appearance: surface roughness 12.5; Product quality: meets standards TB/T2427 and TB/T1464 | Casting appearance: surface roughness 6.5; Product quality: meets standards TB/T2427 and TB/T1464 |

| Technology | Precision casting or sand casting is used, with high product cost and long production time | Lost foam casting is used, with good appearance quality, shortened production time, and reduced production cost |

| Process | Top gating pouring method is used, with low product qualification rate and low yield. Machining is carried out on a CNC lathe without a special fixture, resulting in low product dimensional accuracy | Bottom gating pouring method is used, with a product qualification rate of over 90% and a yield of 75%. A special fixture is made and machining is carried out in a processing center, doubling the efficiency and greatly improving the product accuracy |

| Equipment | Casting: intermediate frequency furnace melting, multifunctional heat treatment furnace heat treatment; Machining: CNC lathe processing | Casting: intermediate frequency furnace melting, multifunctional heat treatment furnace heat treatment; Machining: making a special fixture and processing in a processing center |

| Quality | Unmachined surface roughness is above 6.3, and machined surface roughness is above 1.6; Product dimensional accuracy: ± 0.05; The product passes non-destructive testing without cracks, subcutaneous pores, internal slag inclusions, and other casting defects |

V. Conclusion

The lost foam casting technology for the ZG25MnCrNiMo high-speed rail shock absorption box has significant advantages. By optimizing the key technologies such as grouping, coating, melting, and pouring, the casting quality of the high-speed rail shock absorption box can be effectively improved, the defect rate can be reduced, and the product performance and service life can be enhanced. The application of this technology can meet the requirements of high-speed rail development and improve the competitiveness of domestic high-speed rail equipment.

In the future, with the continuous development of high-speed rail technology, further research and improvement of the lost foam casting technology for high-speed rail shock absorption boxes are still needed to meet the higher requirements of high-speed rail performance and reliability.