Spheroidal Graphite Cast Iron, also known as ductile iron or nodular iron, has long been valued for its superior mechanical properties and performance compared to traditional gray cast iron. The unique microstructure of Spheroidal Graphite Cast Iron, characterized by spherical graphite nodules, imparts excellent strength, ductility, and toughness. Recent advancements in the production and processing of Spheroidal Graphite Cast Iron have further enhanced its mechanical properties and broadened its application range. This article explores these advancements and their impact on the performance of Spheroidal Graphite Cast Iron.

Understanding Spheroidal Graphite Cast Iron

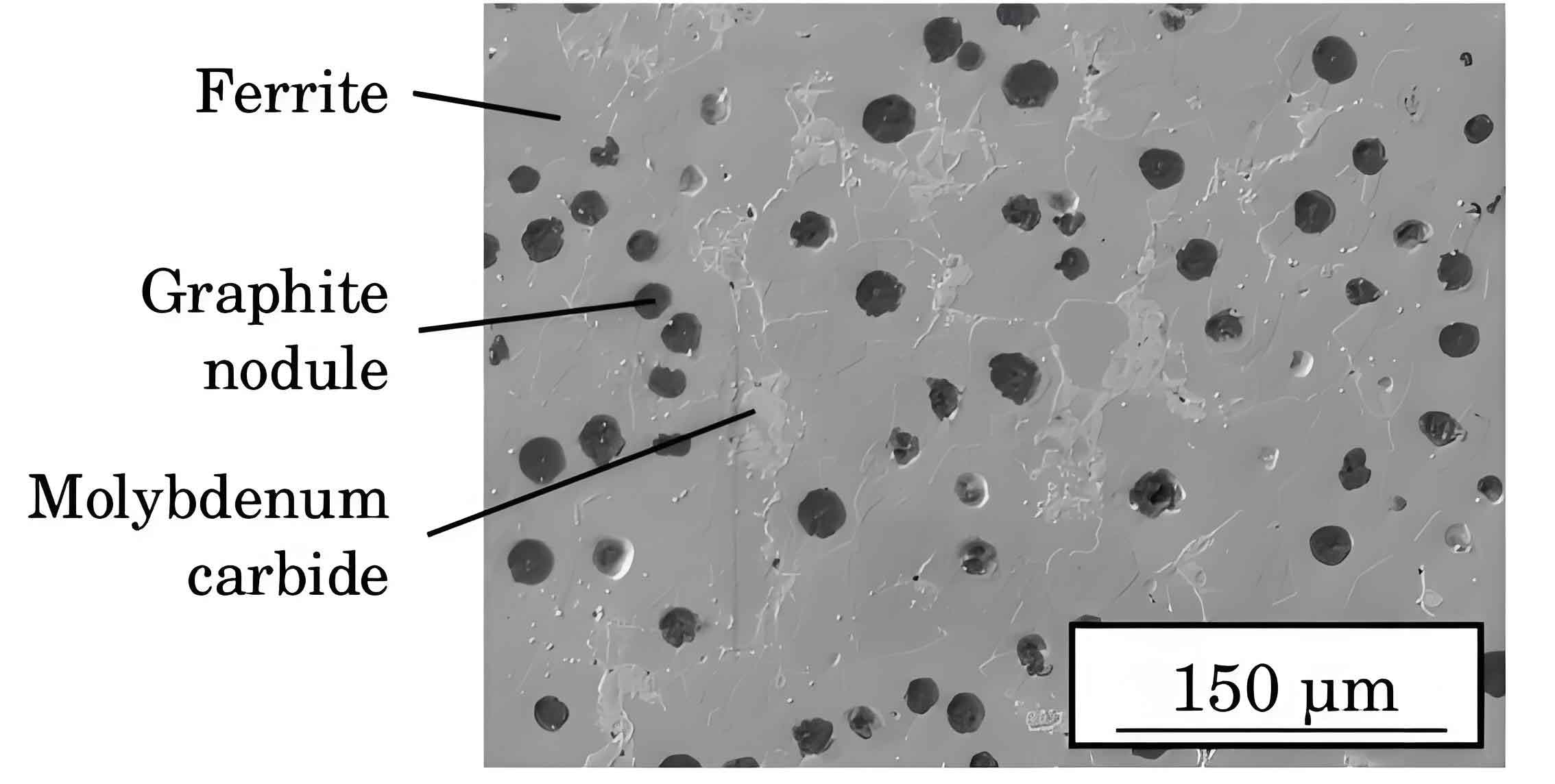

Spheroidal Graphite Cast Iron is a type of cast iron that contains graphite in the form of spheroids or nodules. This microstructure significantly enhances the material’s mechanical properties compared to traditional gray cast iron, where graphite exists in flake form.

Key Properties of Spheroidal Graphite Cast Iron

- High Tensile Strength: Spheroidal Graphite Cast Iron exhibits higher tensile strength than gray cast iron.

- Excellent Ductility: The spheroidal graphite structure provides superior ductility and impact resistance.

- Good Fatigue Resistance: Spheroidal Graphite Cast Iron demonstrates excellent fatigue resistance, making it suitable for dynamic applications.

- Good Wear Resistance: The material offers good wear resistance, essential for components subjected to friction and wear.

Table 1: Comparison of Key Properties

| Property | Spheroidal Graphite Cast Iron | Gray Cast Iron |

|---|---|---|

| Tensile Strength | High | Moderate |

| Ductility | Excellent | Poor |

| Fatigue Resistance | Good | Moderate |

| Wear Resistance | Good | Good |

Advancements in Production Techniques

Recent advancements in the production techniques of Spheroidal Graphite Cast Iron have led to significant improvements in its mechanical properties and performance.

1. Inoculation Techniques

Inoculation is a critical process in the production of Spheroidal Graphite Cast Iron, involving the addition of inoculants to the molten iron to promote the formation of graphite nodules.

Improved Inoculation Methods

- Late Inoculation: Adding inoculants just before casting to ensure uniform distribution of graphite nodules.

- Multi-Stage Inoculation: Using multiple inoculation stages to enhance the consistency and quality of graphite nodules.

List 1: Improved Inoculation Methods

- Late inoculation for uniform nodule distribution.

- Multi-stage inoculation for enhanced nodule consistency.

2. Alloying Additions

Alloying elements play a crucial role in enhancing the mechanical properties of Spheroidal Graphite Cast Iron. Recent research has focused on optimizing the composition of these alloys.

Key Alloying Elements

- Magnesium: Essential for the formation of spheroidal graphite nodules.

- Copper and Nickel: Improve strength and toughness.

- Molybdenum: Enhances high-temperature strength and corrosion resistance.

Table 2: Key Alloying Elements and Their Effects

| Alloying Element | Effect on Properties |

|---|---|

| Magnesium | Promotes formation of spheroidal graphite nodules |

| Copper | Increases strength and toughness |

| Nickel | Enhances toughness and fatigue resistance |

| Molybdenum | Improves high-temperature strength and corrosion resistance |

3. Heat Treatment Processes

Advanced heat treatment processes have been developed to further enhance the mechanical properties of Spheroidal Graphite Cast Iron.

Heat Treatment Techniques

- Austempering: A heat treatment process that produces a bainitic microstructure, improving strength and toughness.

- Normalizing: Heating the iron to a high temperature and then air cooling to refine the microstructure and enhance mechanical properties.

- Annealing: Reducing hardness and improving ductility through controlled heating and cooling cycles.

List 2: Heat Treatment Techniques

- Austempering for bainitic microstructure.

- Normalizing for refined microstructure.

- Annealing for reduced hardness and improved ductility.

Enhanced Mechanical Properties and Performance

The advancements in production techniques have led to significant improvements in the mechanical properties and performance of Spheroidal Graphite Cast Iron.

Improved Mechanical Properties

- Higher Strength: Enhanced tensile and yield strength due to optimized alloying and inoculation.

- Better Ductility: Increased elongation and impact resistance through improved microstructural control.

- Superior Fatigue Resistance: Enhanced fatigue life due to uniform distribution of graphite nodules and refined microstructure.

Table 3: Enhanced Mechanical Properties

| Property | Improvement |

|---|---|

| Tensile Strength | Higher tensile strength |

| Yield Strength | Improved yield strength |

| Ductility | Increased elongation and impact resistance |

| Fatigue Resistance | Enhanced fatigue life |

Performance Benefits

- Extended Service Life: Components made from advanced Spheroidal Graphite Cast Iron exhibit longer service life due to improved mechanical properties.

- Reduced Maintenance: Enhanced wear and fatigue resistance result in lower maintenance requirements.

- Greater Design Flexibility: The improved properties allow for more complex and demanding designs in various applications.

List 3: Performance Benefits

- Extended service life of components.

- Reduced maintenance requirements.

- Greater design flexibility for complex applications.

Applications of Advanced Spheroidal Graphite Cast Iron

The enhanced properties of Spheroidal Graphite Cast Iron have expanded its application range across various industries.

Automotive Industry

- Engine Components: Crankshafts, camshafts, and connecting rods benefit from the high strength and fatigue resistance.

- Suspension Systems: Control arms and suspension knuckles utilize the material’s excellent ductility and impact resistance.

Aerospace Industry

- Landing Gear: Spheroidal Graphite Cast Iron is used in landing gear components due to its strength and toughness.

- Engine Parts: Turbine housings and other high-temperature components benefit from the material’s enhanced properties.

Industrial Machinery

- Pumps and Valves: The wear resistance and strength of Spheroidal Graphite Cast Iron make it ideal for pumps, valves, and other industrial equipment.

- Heavy Machinery: Components such as gears and bearings leverage the material’s mechanical properties for demanding applications.

Table 4: Applications of Spheroidal Graphite Cast Iron

| Industry | Applications |

|---|---|

| Automotive | Engine components, suspension systems |

| Aerospace | Landing gear, engine parts |

| Industrial Machinery | Pumps, valves, gears, bearings |

Conclusion

Advancements in the production and processing of Spheroidal Graphite Cast Iron have significantly enhanced its mechanical properties and performance, making it a highly versatile material for various demanding applications. Through improved inoculation techniques, optimized alloying additions, and advanced heat treatment processes, sand casting manufacturers have been able to produce Spheroidal Graphite Cast Iron with superior strength, ductility, and fatigue resistance. These enhancements not only extend the service life of components and reduce maintenance requirements but also provide greater design flexibility for engineers and designers. As research and development continue to drive innovation in this field, the future of Spheroidal Graphite Cast Iron looks promising, with even more potential for performance improvements and new applications.