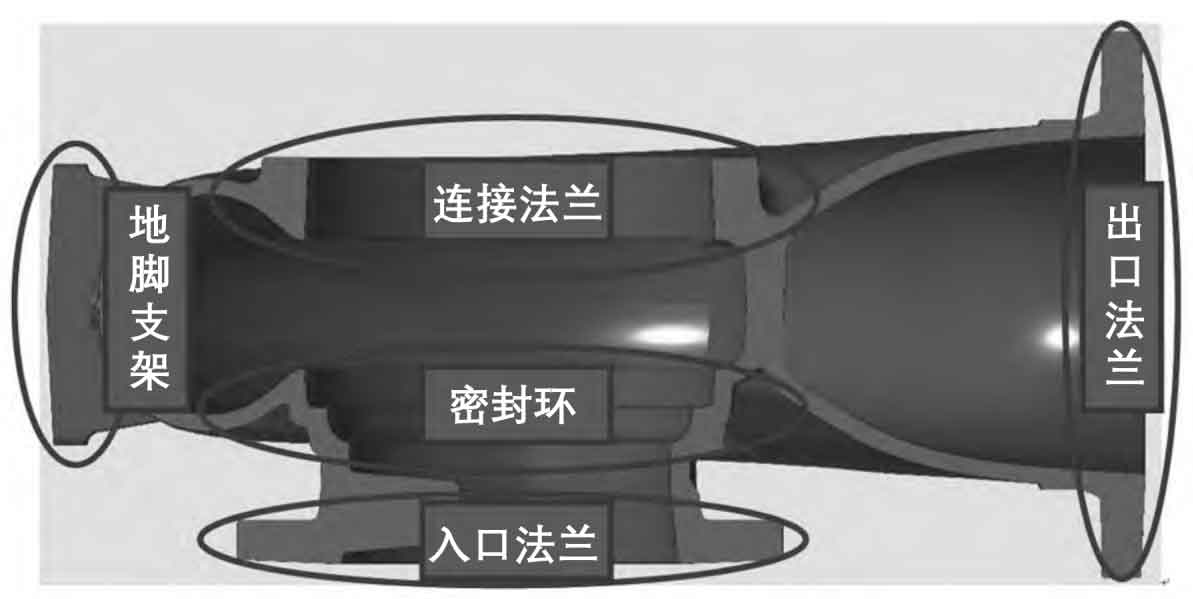

The single suction pump casing is a box type casting, and its structure is shown in the figure. Casting defects are mainly divided into two categories, namely, internal shrinkage defects and inclusion defects.

Firstly, the internal shrinkage defect is analyzed. The main wall thickness of the research object is 20mm. According to the author’s experience, the cast steel structure below 30mm can realize self feeding, so the internal quality problem does not need to be considered in the main wall thickness area; In the center of the pump casing, three annular structures of inlet flange, seal ring and connecting flange are stacked from bottom to top. The three areas are divided by the main wall thickness of the pump casing, so mutual feeding cannot be realized, forming a composite heat junction. The above three areas, together with the inlet flange and the anchor support, become the centralized location of internal quality problems of the pump casing. The application scenario of the pump determines that the pump casing casting needs to undergo strict sealing test, and the casting defects at these positions often lead to the failure of the sealing test, which constitutes the main reason for the scrapping of the pump casing in actual production.

Inclusion is another main reason for scrapping pump casing castings. The inclusions in the pump casing castings are mainly silicate inclusions, which are large in size and irregular in appearance, mainly caused by refractory materials, mold slag and slag entering the molten steel during production.