1) Production process of frame sand casting

The sand casting of the frame adopts the pit shape and box cover, and the pit depth is 1000mm. The surface sand used for modeling is chromite sand, and the back sand is quartz sand. The binder used is water glass and the hardening method of carbon dioxide gas is adopted. Due to the large wall thickness and high pouring temperature of the casting, in order to prevent sand sticking during pouring, alcohol based cuoying sand coating shall be applied on the surface of the mold and core wall, and its thickness shall not be less than 1mm. The thickness of the surface sand layer is 20-30mm, and the thickness of the middle sand layer is 100-150mm. During pouring, a two-stage, double-layer stepped pouring system is adopted, and a concealed pressing iron with a total weight of 100t is placed on the box cover. The initial pouring temperature is 1560-1580 ℃, and the cavity is preheated by hot air for 8 hours (about 150 ℃). The castings shall be kept warm in the sand box for 10-15 days from pouring to sand falling.

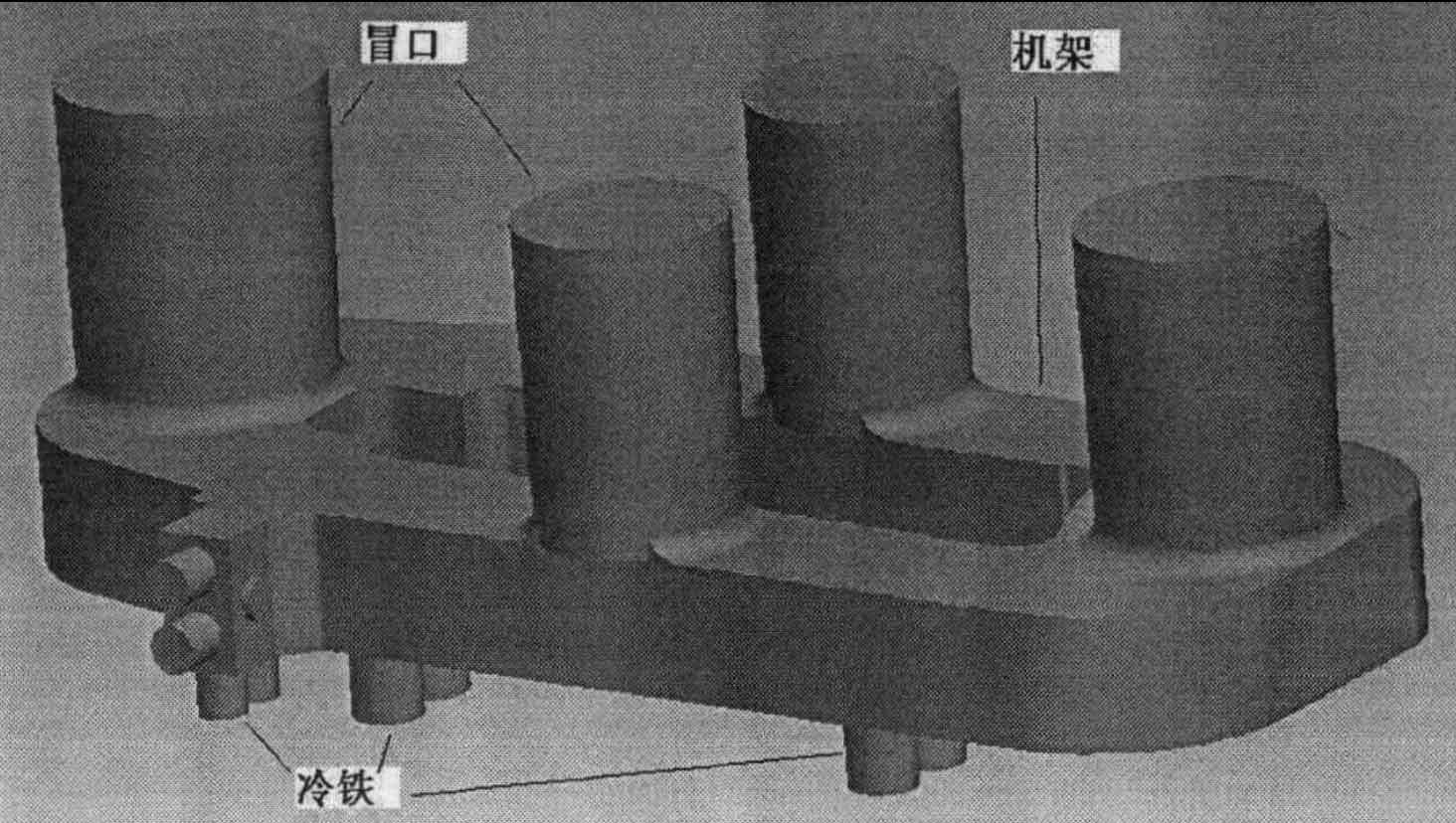

2) Design of riser for frame sand casting

Only the solidification process of sand casting frame is simulated, so the design of gating system is not introduced. In the sand casting process of the frame, a large riser is used to supplement the solidification of the casting. The total number of risers is 4. The risers are placed symmetrically, which are located in the middle of the beam and column respectively, with a total weight of 30t. Two large risers are respectively located at both ends of the cross beam of the sand casting frame to feed the thick parts of the casting: two small risers are located in the middle of the column to feed the solidification of the column.

3) Arrangement of chill in sand casting of frame

It is far from enough for the cooling and solidification of sand casting frame to rely on four large and small risers for feeding. Shrinkage porosity will appear in the thick part of the column. Therefore, it is also necessary to arrange sand cold iron between the large and small risers to control the solidification sequence and prevent shrinkage porosity. In the process of sand casting, a total of 16 large and small cold irons are arranged outside the large and small risers and the column. Arranged between large and small risers Φ There are 8 pieces of 300×300 sand hanging cold iron. The thickness of sand hanging cold iron is 30-40mm, which is used to control the solidification sequence and expand the feeding distance of riser. The outer side of the column is arranged in total Φ There are 8 200×200 external cooling irons in total, which are used to avoid stress concentration and crack defects caused by too fast solidification on the outside. The three-dimensional drawing of the complete sand casting process after design is shown in the figure.