The properties of tensile samples were tested by a universal testing machine controlled by microcomputer, and the tensile strength and lower yield strength of each sampling part were tested.

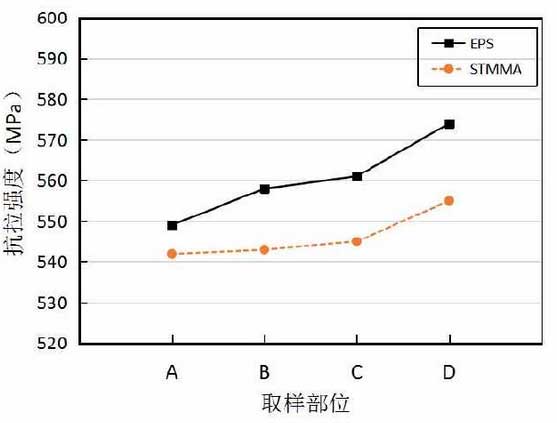

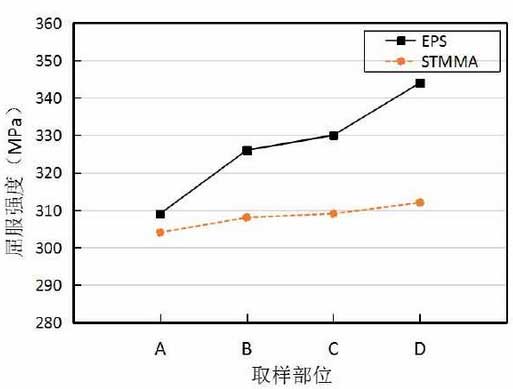

With the different sampling locations, the tensile strength and yield strength of cast steel castings produced by the same foamed materials are not increased, but they vary from high to low. The results show that the mechanical properties of steel castings with stmma are more stable. From the average value, the overall trend is from a to d according to the sampling position, as shown in Fig. 1 and Fig. 2, which is basically consistent with the change trend of carbon content in volume carburization. The ratio of steel castings to the same sampling location and foamed materials is significantly higher than that of STMMA castings, and the tensile strength and yield strength of EPS castings are higher. The above two points show that the tensile strength and yield strength of steel castings increase with the increase of carbon content.

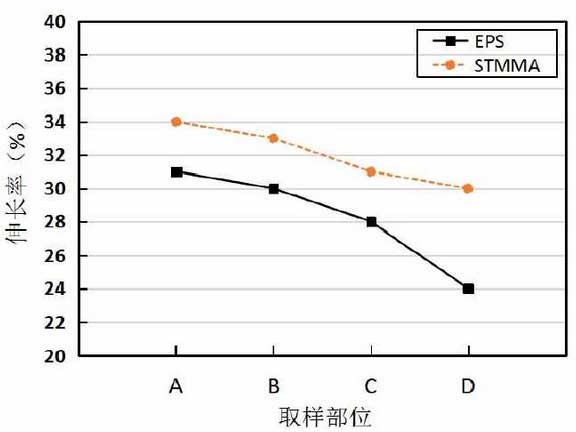

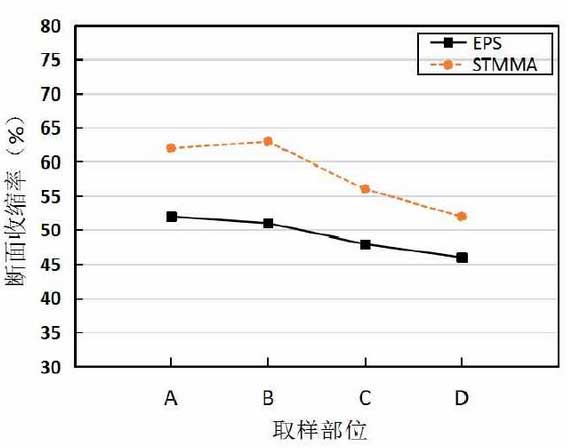

Test results of elongation after fracture and reduction of area of each sampling part. It can be seen from the results that the test results of the same foam material and different sampling parts are in transverse contrast. According to the sampling location, with the increase of carbon content, the elongation at break and the shrinkage of the section show a slight downward trend, as shown in figures 3 and 4. When comparing the experimental results of the same sampling location and different foam materials, as the carbon content of EPS material is higher than that of STMMA material, it is obvious that the higher the carbon content is, the greater the decrease of elongation and sectional shrinkage. This shows that the carburizing defect is an unfavorable factor for elongation and reduction of area. However, the results of all tests are within the acceptable range.