Six groups of samples were taken when analyzing surface carburization, and the location of the test point was changed to the center of the sample section, so as to analyze the volume carburization and carbon content test results inside the casting.

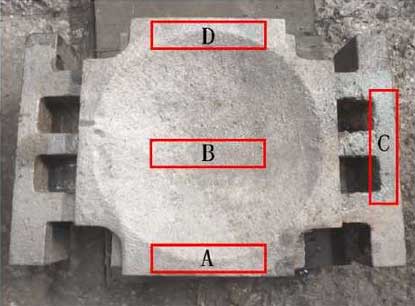

It can be seen that the influence degree of volume Carburization on the chemical composition of each sampling position is d > C ≈ b > A, that is, the most serious part of volume carburization is the top of the casting far away from the inner gate, and the lightest part of the volume carburization is the part near the gate. When EPS is used, the average range of carburization is between 0.013% and 0.034%, and the highest value is less than 0.04%; when using stmma copolymer, the average range of carburization is between 0.001% and 0.012%, and the highest value is less than 0.015%.

The increase of volume carburization is much less than that of surface carburization. Some studies have shown that alloying elements play a major role in the volume carburization of cast steel, and the carbide forming elements all hinder the diffusion of carbon and hydrogen in the front of molten steel, so the process of carburizing and hydrogen increasing in the volume of molten steel is restrained. The steel zgs10crnicu is a low-carbon alloy steel. Cr and Mn in the steel are carbide forming elements with a total content of less than 2%. Although it is not as effective as high alloy steel in curbing carburization, it also hinders the diffusion of carbon in molten steel to a certain extent.

When EPS is used to produce steel castings, the volume carburization will lead to the local chemical composition of castings exceeding the standard requirements and unqualified; when using stmma copolymer to produce steel castings, the volume carburization is very small, which has little impact on the chemical composition, and no unqualified component is detected in each sampling position.