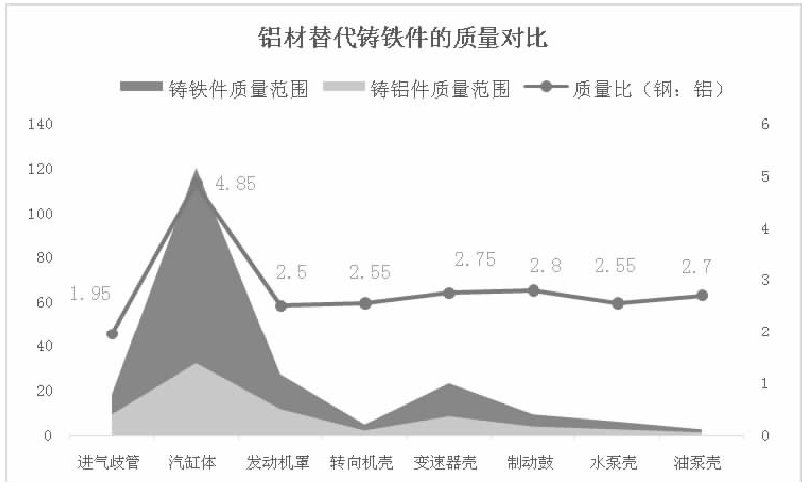

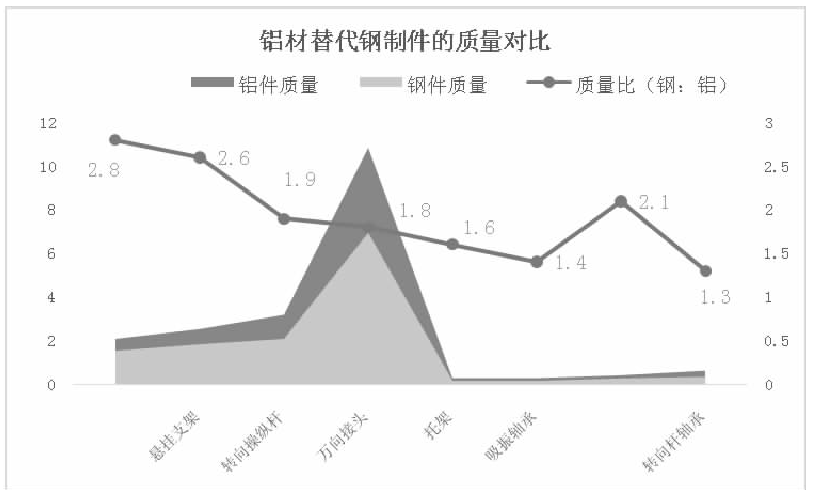

Aluminum alloy can replace most of the parts, and steel for automobile has a large proportion. Most of the steel parts can be replaced by aluminum alloy, including engine, wheel hub, heat exchanger, body, steering shaft, transmission bracket, instrument panel structure, suspension subframe, etc. At present, the penetration rate of aluminum alloy in gearbox, wheel hub, heat exchanger and other fields is high. In the future, with the improvement of body aluminum technology, the aluminum consumption of automobile engine and body is expected to gradually increase.

Aluminum alloy is second only to steel in automotive metal materials, automotive aluminum can be divided into two parts: aluminum alloy and aluminum matrix composites; automotive aluminum alloy is divided into casting and deformation aluminum alloy. Among them, casting aluminum alloy is transformed from liquid metal to solid, that is liquid forming; deformation aluminum alloy is transformed from solid powder to solid metal, that is solid forming.

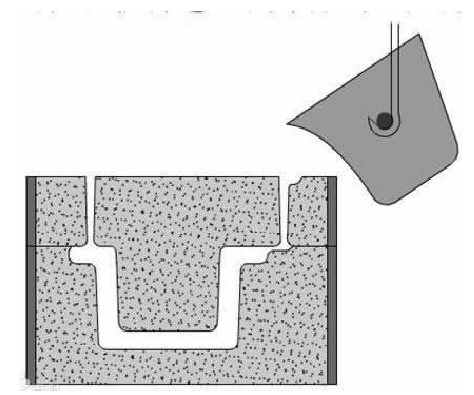

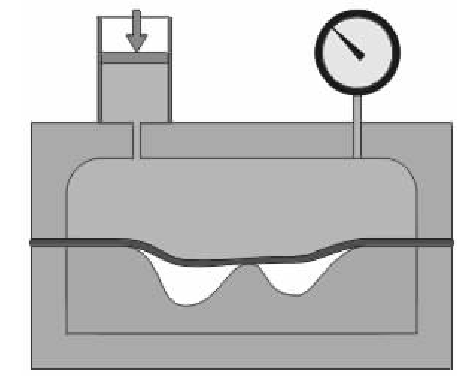

At present, there are four kinds of aluminum alloy used in automobile, including cast aluminum alloy, forged aluminum alloy, extruded aluminum alloy and aluminum alloy plate. Casting aluminum alloy is divided into sand casting, lost foam casting, semi-solid casting, squeeze casting and permanent casting. A356 is commonly used as cast aluminum alloy. The dendritic crystal structure in the as cast metallographic structure affects the strength and toughness of the casting, and limits its application in moving components. After optimizing the composition, it is expected to replace the wheel of commercial vehicles and reduce the cost. Forged aluminum alloy has a wide range of application prospects in automobile, such as suspension support and wheels; after the application of commercial vehicle wheels, the effect of energy saving and emission reduction is obvious. Aluminum alloy extrusion process is simple, the interface shape can be designed, and it is mostly used in front and rear bumpers of passenger cars; it can not only meet the requirements of impact and energy absorption, but also reduce the weight of components, with the weight reduction rate of 40% ~ 50%. Deformable aluminum alloy sheets are mostly used for body panels and front and rear bumper anti-collision beams.

With the improvement and application of aluminum alloy parts and the gradual maturity of automotive aluminum alloy technology, all kinds of castings and extrusion parts with complex structure and performance meeting the requirements can be mass produced, and the cost driven by technological progress will drop. More aluminum alloy parts with complex structure and high cost will be introduced into the automobile.