Lost foam casting requires that the molding sand can fill the mold space tightly during molding. Therefore, the vibrating system is one of the key equipment. The factors affecting the compaction effect include molding sand, sand adding device, sand box, compaction table and control system. Baozhu sand is better than quartz sand because it is nearly spherical; The stiffness and consistency of the sand box are good to ensure that the exciting force of the lost foam casting vibrating table can be well transmitted to the molding sand; The vibrating table and its control system of lost foam casting are the source of exciting force and the basis of determining the filling capacity of molding sand.

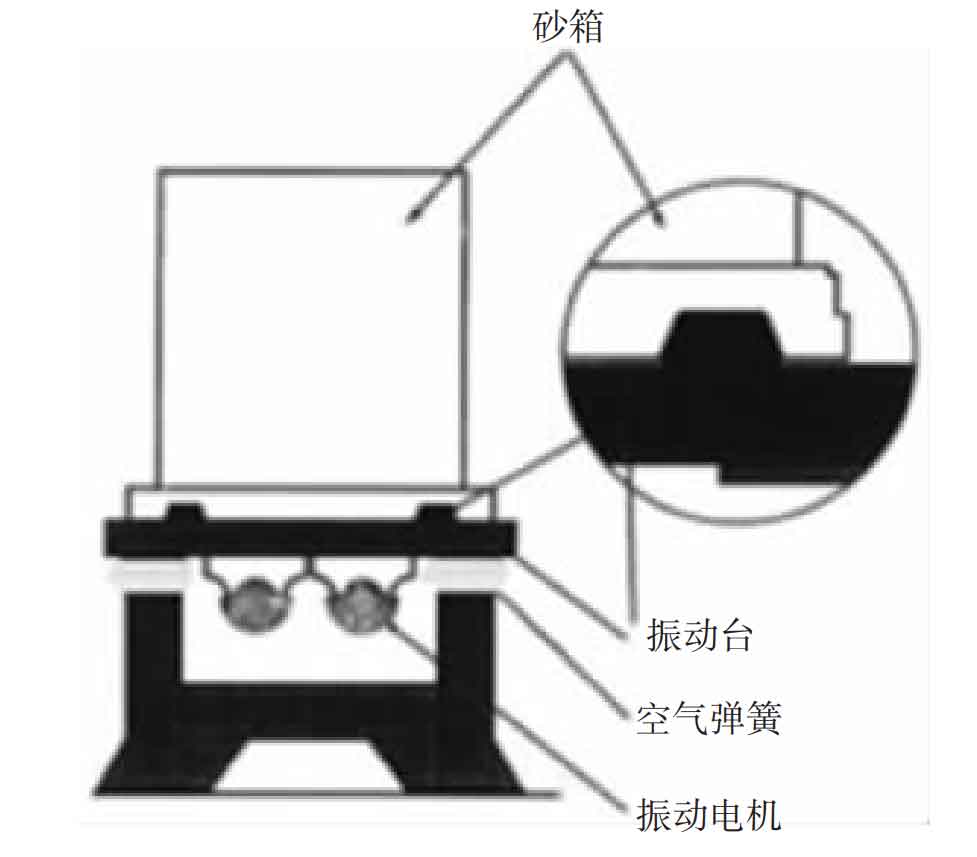

Figure 1 shows the basic structure of GK lost foam casting vibrating table in the United States. The sand box is not clamped. The lost foam casting vibrating table has three convex round tables, and the bottom of the sand box corresponds to three pits. The vibration acceleration can reach 1.6 ~ 2.2 g, and the irregular transverse excitation force is generated by the side impact of the circular platform.

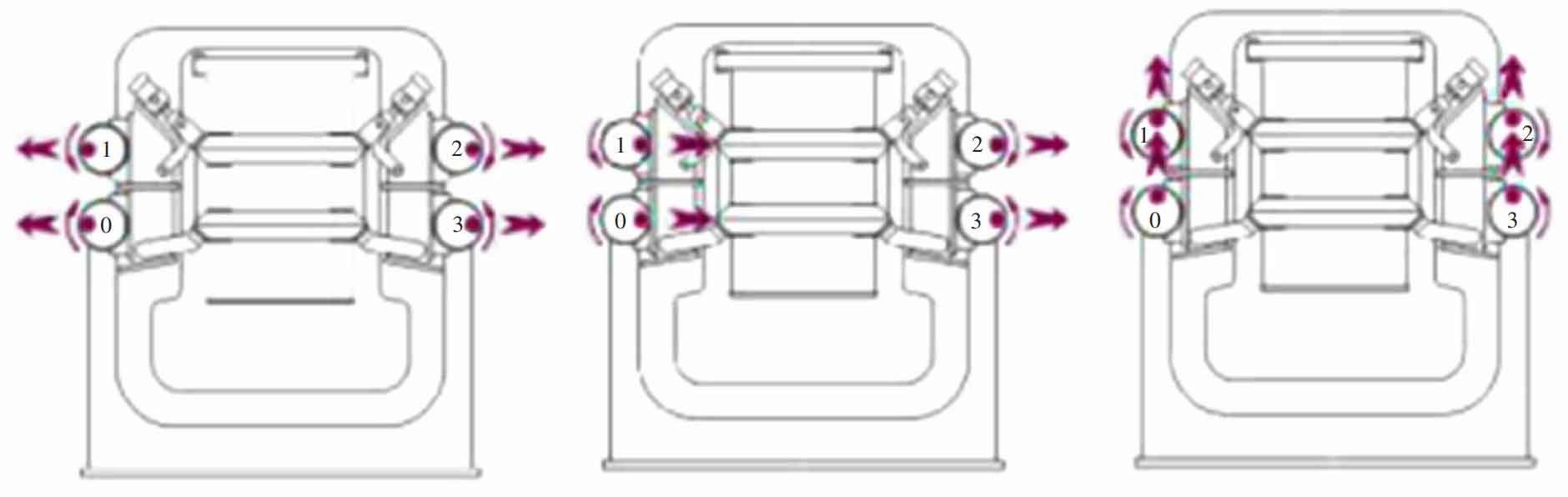

Figure 2 shows the basic structure of Vulcan lost foam casting vibrating table in the United States. The sand box is surrounded by the frame of lost foam casting vibrating table. After the lost foam casting vibrating table is lifted, the sand box is lifted on the 45 ° surface at the bottom 4, and the top is pressed on the 45 ° surface at the upper 4 by hydraulic drive. The excitation force comes from four vibration motors installed on both sides. The motor is connected with the position feedback encoder. The encoder can detect the motor speed and the included angle between the eccentric block and the reference, so as to ensure that the motor 1, 2 and 3 have an accurate phase angle relative to the motor. Through the control of this phase angle, the vibration at any angle in the plane can be realized theoretically.

There are many types of lost foam casting vibrating tables produced by domestic equipment manufacturers, which can be mainly divided into sand box clamping type and sand box non clamping type. There are double motors, 4 motors and 6 motors in each type. However, from the effect fed back by the manufacturer, the horizontal filling capacity is not ideal, and yellow mold pre plugging resin sand is often required.

(1) After the finite element analysis of the existing sand box, the adaptive structure design and transformation of the sand box is carried out to improve the stiffness and vibration consistency of the sand box;

(2) By studying the compaction law of lost foam casting vibrating table, a new type of vibrating equipment was developed. By controlling the filling angle, the transverse filling can reach 100 mm, and the waste rate of bonded sand decreased from 2.76% to 0.67%;

(3) The use of the new lost foam casting vibrating table significantly reduces the Z-dimensional deformation and reduces the scrap rate of machining deformation from 2.9% to 0.65%.

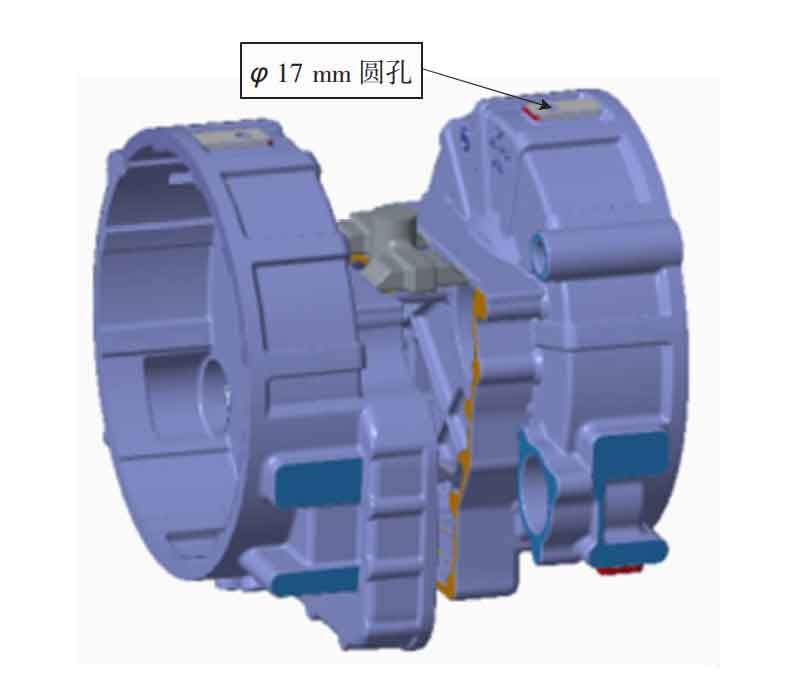

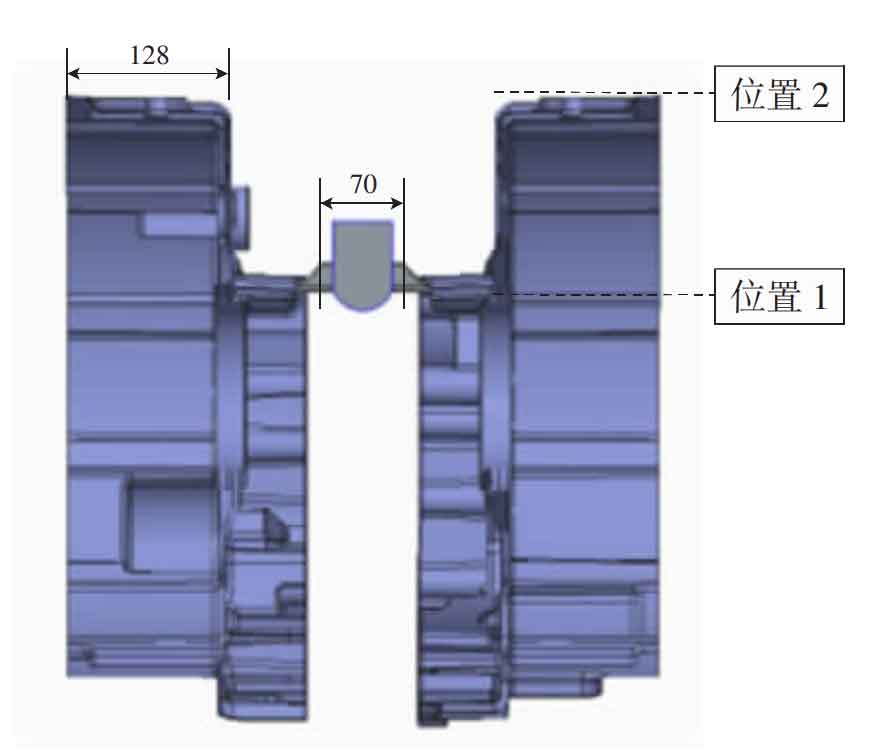

The flywheel housing is placed vertically in the sand box (as shown in Fig. 3), and there are two parts to be filled (as shown in Fig. 4). Position 1 needs to be filled laterally by 70 mm, position 2 needs to be filled laterally by 128 mm, and there is one 53 mm away from the filling root φ 17 mm round hole. For position 1, 0 ° reciprocating vibration is adopted, the force is 76%, and the time is 32 s; Position 2, 30 ° unidirectional vibration, force 78%, time 30 s; 150 ° unidirectional vibration, 78% force and 30 s time. The vibration was carried out according to the above process, a total of 16 pieces were debugged and verified, and there was no sand sticking in 2 places. In the later production, the scrap rate of bonded sand decreased from 2.76% to 0.67%.

According to the transverse and longitudinal measurement of the inner diameter of the flywheel housing stop, it can be seen that the deformation of the stop is significantly improved, and the difference between the transverse and longitudinal diameters is 0.5 mm, which is significantly improved compared with the previous 1.8 mm.

By using the new lost foam casting vibrating table, the Z-dimensional deformation is significantly reduced, and the relevant scrap rate is reduced from 2.9% to 0.65%.