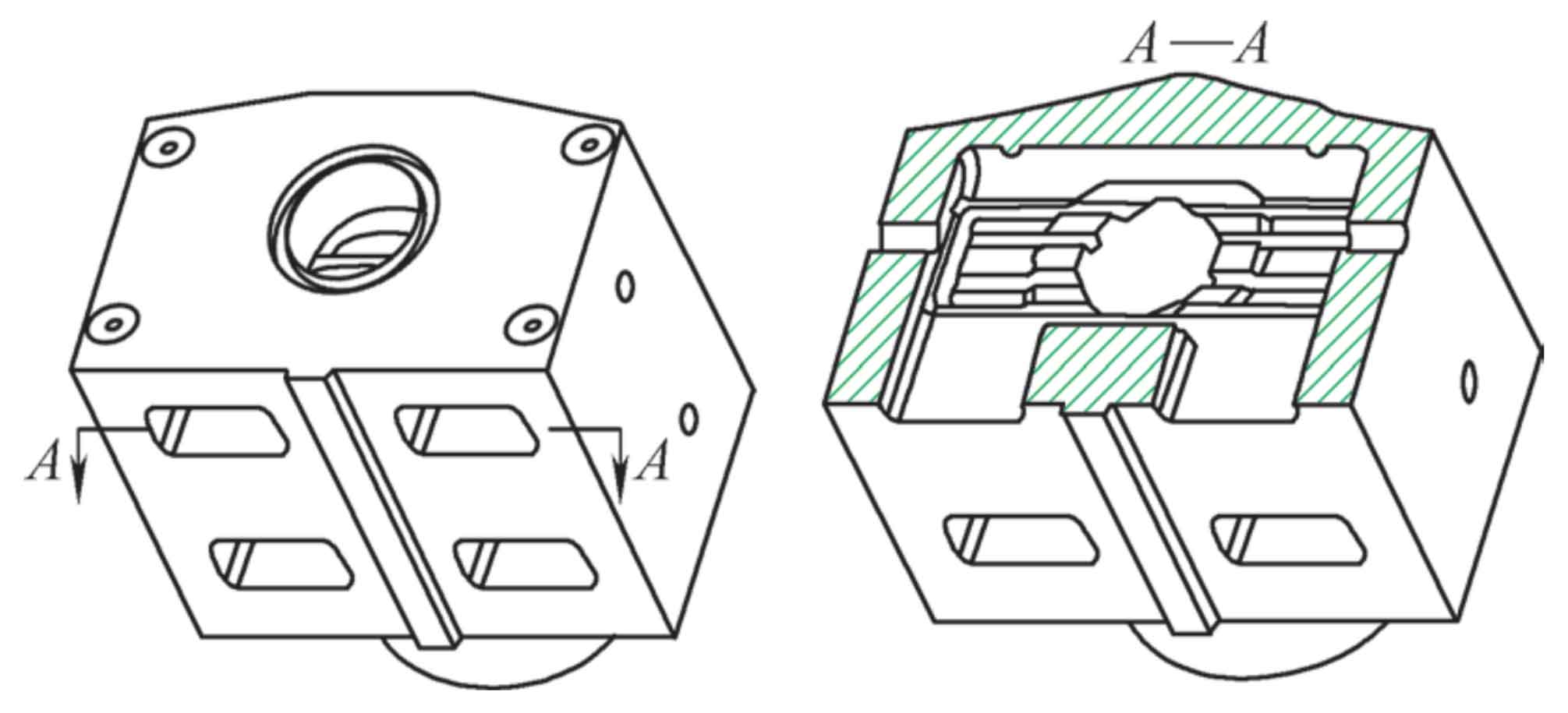

Oil and gas play an important role in the energy field, and the oil and gas service industry is closely related to the development of oil and gas. With the international oil service giants such as Baker Hughes in the domestic market layout, the high-end market demand is also gradually strengthening. The BOP supporting shell casting is the core part of oil and gas deep well drilling. Its role is to take emergency action on the BOP in case of oil spill at the wellhead during the oil drilling process to achieve rapid shut-in action. Because the material is made of medium-high carbon low-alloy high-strength steel, the comprehensive mechanical properties of the BOP shell castings, especially the hardness and its deviation range, are very high, and the requirements for the inner cavity size are very high, which is not easy to process. It is a high-end casting. At present, there is no precedent for the production of this product by casting in China.

Through the optimization of casting process, the molding process is easy to operate, the wall thickness of BOP shell casting is reasonably controlled, and the sand sticking in the inner cavity oil tank is well controlled. The first repair welding rate of BOP shell castings reached 0.5dm3/t, and the chemical composition and mechanical properties of BOP shell castings met the requirements of customer specifications. Through actual production verification, it can be mass produced.

The solidification and mold filling simulation of the designed process of the blowout preventer is carried out by using the MAGMA software. According to the results of Porosity, Niyama and other criteria, the designed casting process of the blowout preventer will not produce excessive casting defects in theory. The actual detection of the oil groove in the inner cavity of the blowout preventer shell casting is free of sand, and the blowout preventer shell casting is free of shrinkage porosity, shrinkage and other defects, which can be used for field production test.