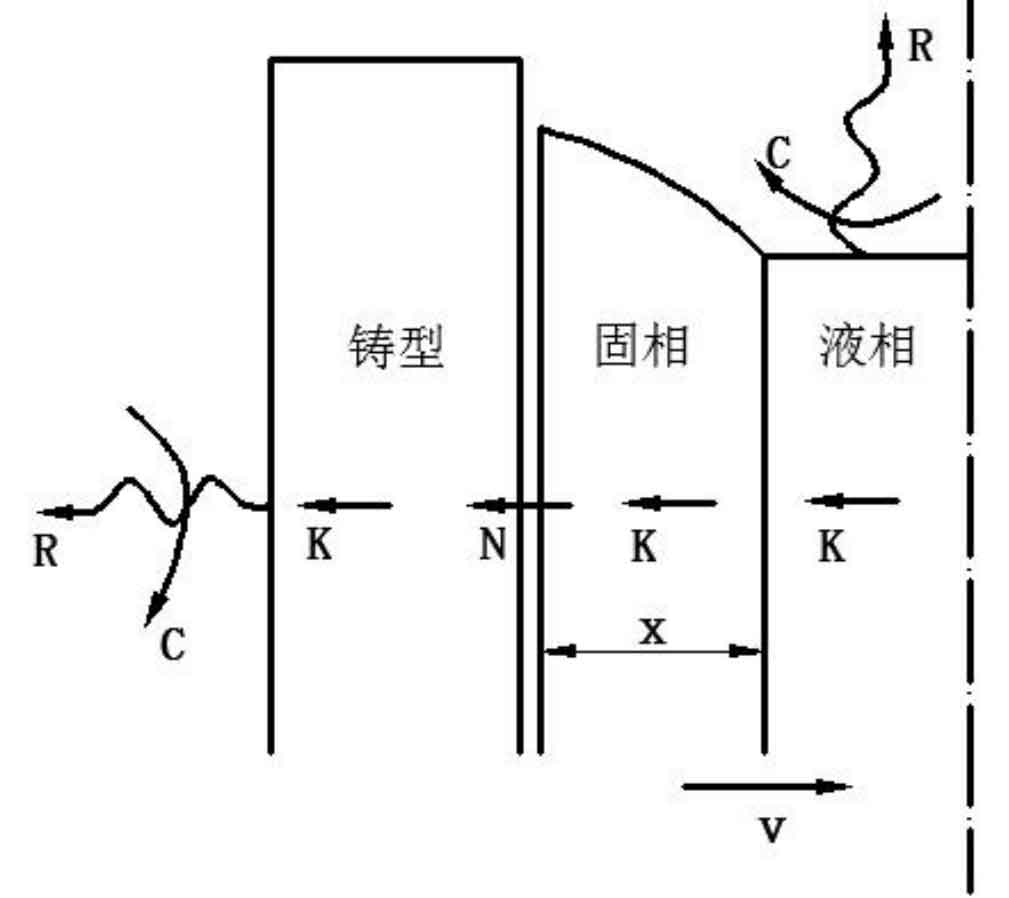

In the process of metal solidification during sand casting, the solidification volume contraction of metal and the thermal expansion of mold make the metal / mold interface layer formed between metal and mold during sand casting. The interface contact state changes dynamically during solidification, from ideal contact to non ideal contact, and the heat transfer between metal and mold during sand casting is not simple heat conduction, There are micro heat convection and heat radiation at the same time. Fig. 1 is a schematic diagram of the heat transfer model after the molten metal is poured into the mold during sand casting. Ideal contact means that the contact surfaces of the casting and the mold have the same temperature, close to each other and have no air gap, and there is no thermal resistance between the default interfaces. Non ideal contact is that a thin gas layer is formed between the thermal expansion of the mold at the initial stage of solidification and the solidification shrinkage of the metal during sand casting. The contact between the two is usually incomplete (i.e. the formation of gap or air gap). There is an interface temperature difference ∆ t between the sand casting and the mold interface, so there is a contact thermal resistance or interface thermal resistance between them.

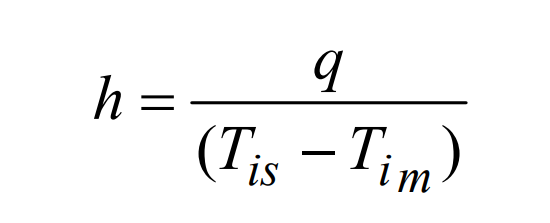

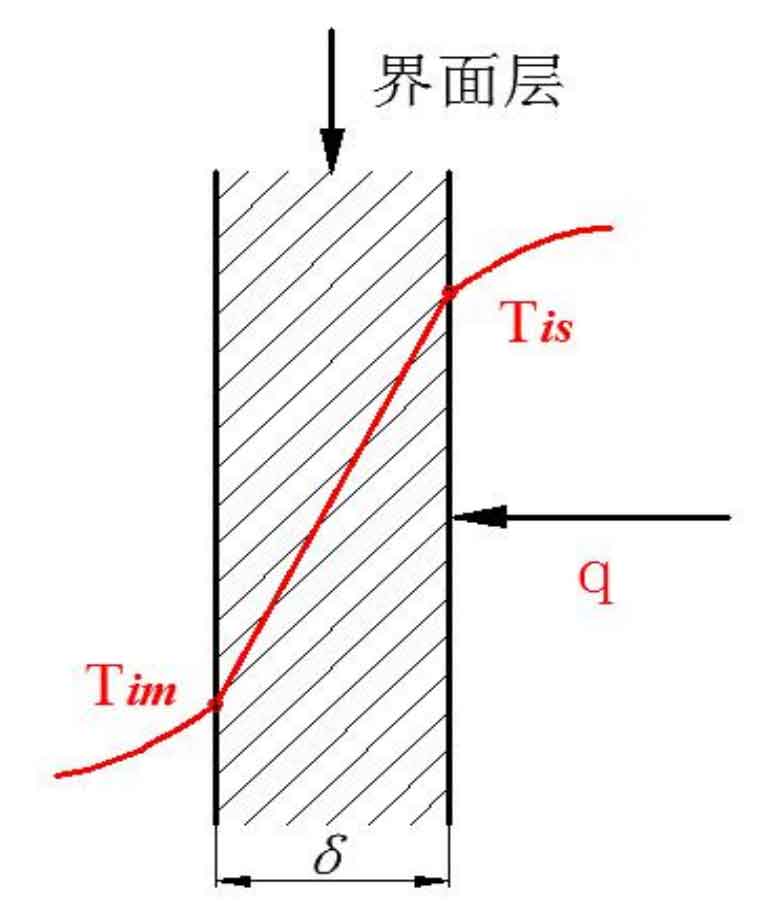

With the solidification of molten metal in sand casting, the contact state of castings / molds will continue to change, and the heat transfer between castings / molds becomes complex and cannot be analyzed quantitatively. Therefore, it is necessary to introduce the parameter for calculating the heat transfer capacity, i.e. the interface heat transfer coefficient h, whose macro definition is like the formula. It is not the physical property value, but the macro performance of the heat transfer capacity between the mold / casting. Its value determines the solidification cooling rate of the sand casting and has a significant impact on the final structure and performance of the sand casting. When the heat flux and temperature at the casting / mold interface are known, the interface heat transfer coefficient can be solved by formula. The macro interface heat transfer model of the interface layer is shown in Figure 2.