For the same sand casting, different pouring speed corresponds to different pouring time. In the process of molten metal entering the mold cavity, if the pouring speed is too small, it will lead to too long filling time, which is easy to cause casting defects such as insufficient pouring; If the pouring speed is too high, it will lead to the violent flow of liquid metal in the mold, resulting in spraying phenomenon, which will lead to slag inclusion or iron beans. Moreover, the liquid metal with too high speed will cause great impact on the mold wall of the sand mold, which is easy to destroy the mold and produce casting defects such as sand holes; The pouring speed also has an effect on the exhaust sequence of the cavity.

| Pouring speed (M / s) | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 |

| Pouring time (s) | 3.40 | 2.97 | 2.65 | 2.38 | 2.16 | 1.98 | 1.83 |

The control of pouring speed is based on pouring time constraints. The theoretical pouring time calculated by the formula in this paper is 2.38s, and the corresponding pouring speed is 1m / s. However, there is a deviation between the theoretical pouring time and the actual pouring time, and this calculation formula is also derived from the actual production experience. Spiral bevel gear is a small steel casting with complex structure, which is rarely used in actual casting production. Therefore, this paper studies the influence of this factor on the forming quality of spiral bevel gear sand casting with pouring speed (corresponding pouring time) as a variable. The specific grouping is shown in the table.

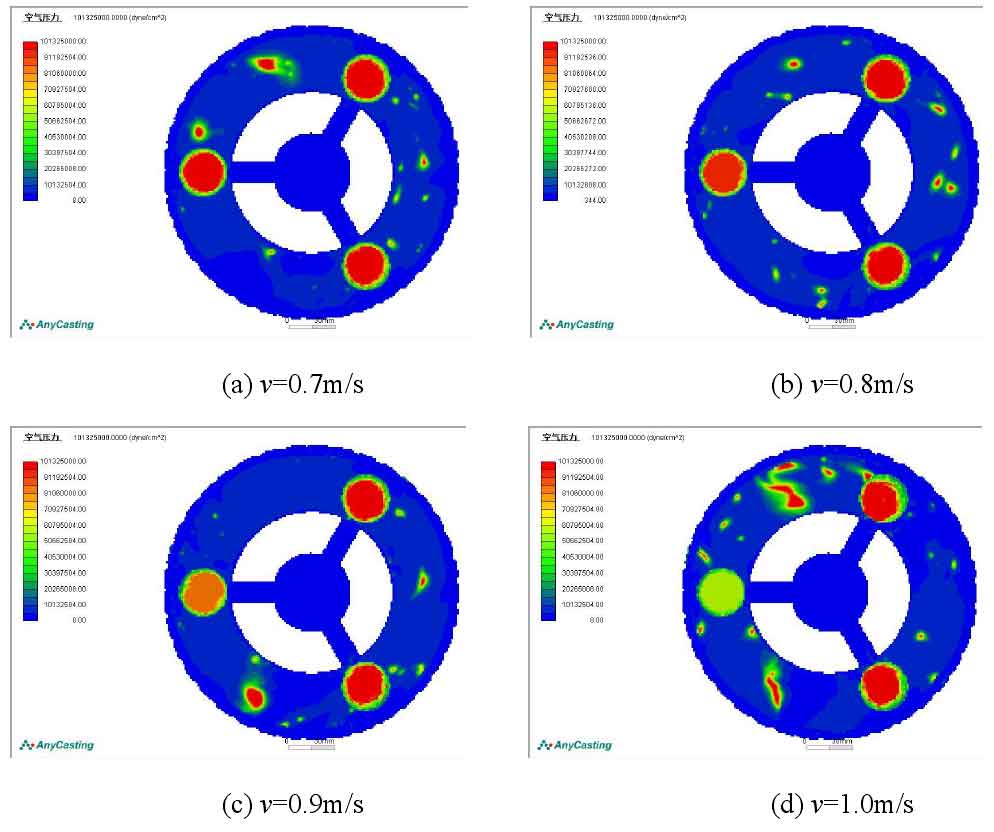

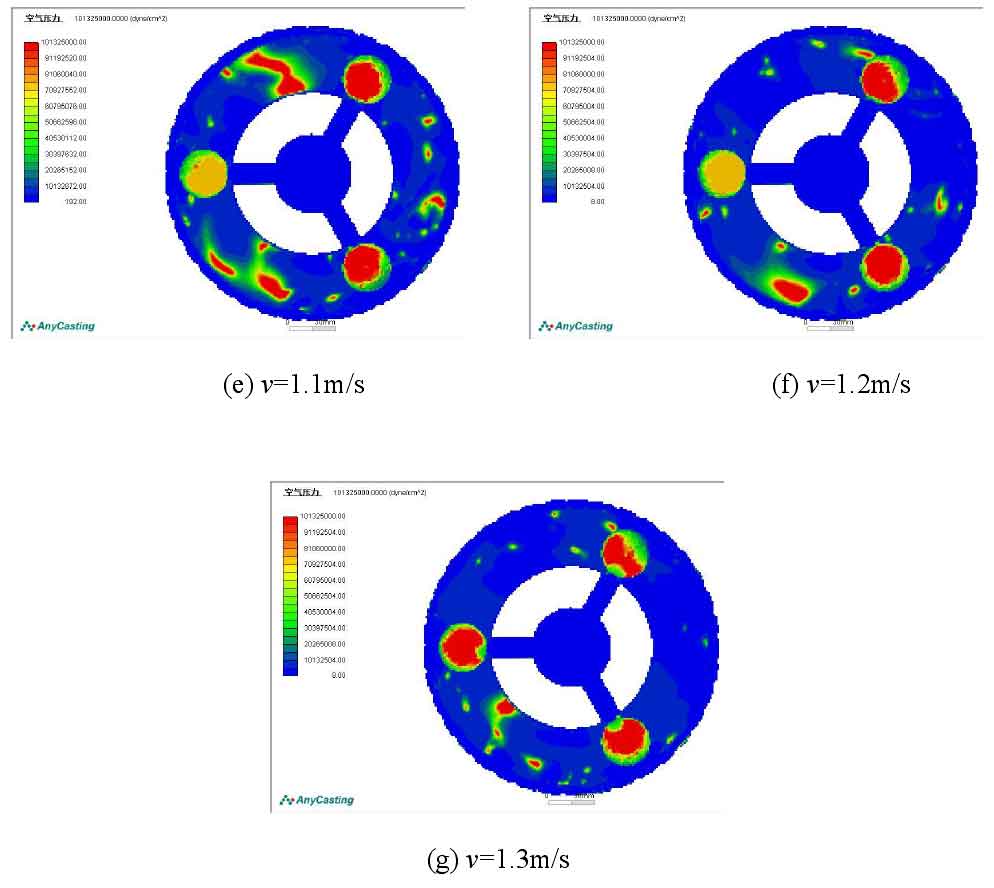

The simulation results show that due to the strong feeding capacity of the insulation riser, the effect of pouring speed on the shrinkage porosity and shrinkage cavity defects of spiral bevel gear sand castings is relatively small; Moreover, when the central top injection pouring scheme is adopted, the liquid metal filling in the mold cavity is stable, and the air and slag can float up to the upper surface of the gear blank; However, the distribution of air pressure on the upper surface of sand castings is different at different pouring speeds. If the air pressure value is too large, there is more residual air, which is easy to lead to casting defects such as pores in sand castings.

The figure shows the air pressure distribution on the upper surface of sand castings at different pouring speeds. By observing the figure, it can be seen that the value and distribution of air pressure on the upper surface of sand casting vary greatly at different pouring speeds. As shown in figure (E), when the pouring speed reaches 1.1m/s, the air in the gear blank mold is not squeezed into the insulation riser, but a considerable part of the air remains in the mold cavity, resulting in a very serious air pressure distribution on the upper surface of the sand casting and a large local pressure value, which will seriously affect the metal structure state of the upper surface of the sand casting. Comprehensive comparison of various schemes shows that when v = 0.8m/s, the air pressure distribution on the upper surface of sand castings is the smallest and the slightest, and the residual air in the mold has the least impact on the forming quality of sand castings. Therefore, it is determined that the optimal pouring speed of the center top pouring scheme for the sand casting of the driven spiral bevel gear is 0.8m/s, and the corresponding pouring time is 2.97s.