The test results are shown in the table.

| Pattern density (g/I) | Total mold filling time (s) | Average filling speed (cm/s) |

| 9 | 0.74 | 27.03 |

| 13.2 | 0.87 | 22.99 |

| 20 | 1.19 | 16.84 |

| 25 | 1.52 | 13.18 |

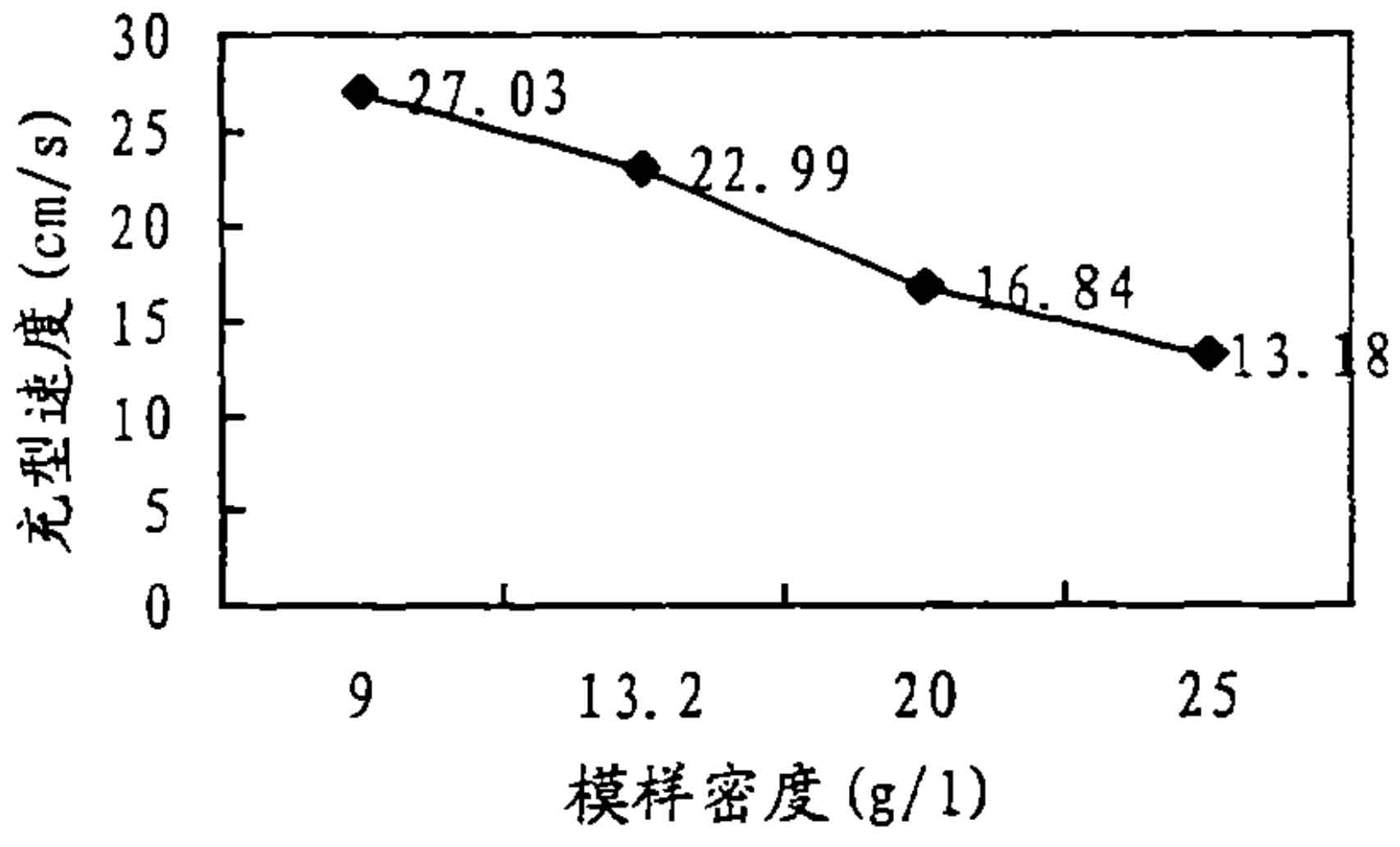

As shown in the figure, the relationship between the average mold filling speed of liquid metal in lost foam casting and the model density is shown when other test conditions are the same. It can be seen from the figure that with the increase of model density, the average filling speed of liquid metal in lost foam casting decreases almost linearly.

The higher the density of the model, the more materials need to be gasified and decomposed, and the heat required for the disappearance of the model also increases proportionally. The higher the density of the model, the more liquid and gas products are produced during the gasification and decomposition, which increases the gas pressure in the mold cavity and the filling resistance of the liquid metal, thus reducing the filling speed and increasing the defects of lost foam casting.

In order to minimize the decomposition products of EPS model and eliminate defects such as bright carbon and carburization, it is hoped that the smaller the model density is, the better. However, when the model density is too small, the model is easy to deform and cannot maintain the required shape correctly in the process of forming, coating, vibration modeling and handling. Therefore, the model density not only affects the amount of gas produced by the decomposition of the model during pouring and the stiffness and strength of the model itself, but also affects the mold filling speed of the liquid metal. The model density is an important factor of the dry sand lost foam casting method. In the dry sand lost foam casting method of gray iron, the model density is controlled between 15-20g / I.