The pouring temperature of cast iron is generally controlled between 1360 ℃ and 1450 ℃. In this paper, the pouring temperatures are 1370 ° C, 1380 ℃, 1390 ℃, 1400 ° C and 1410 ℃, and the effects of different temperatures on the casting process of sand castings are analyzed.

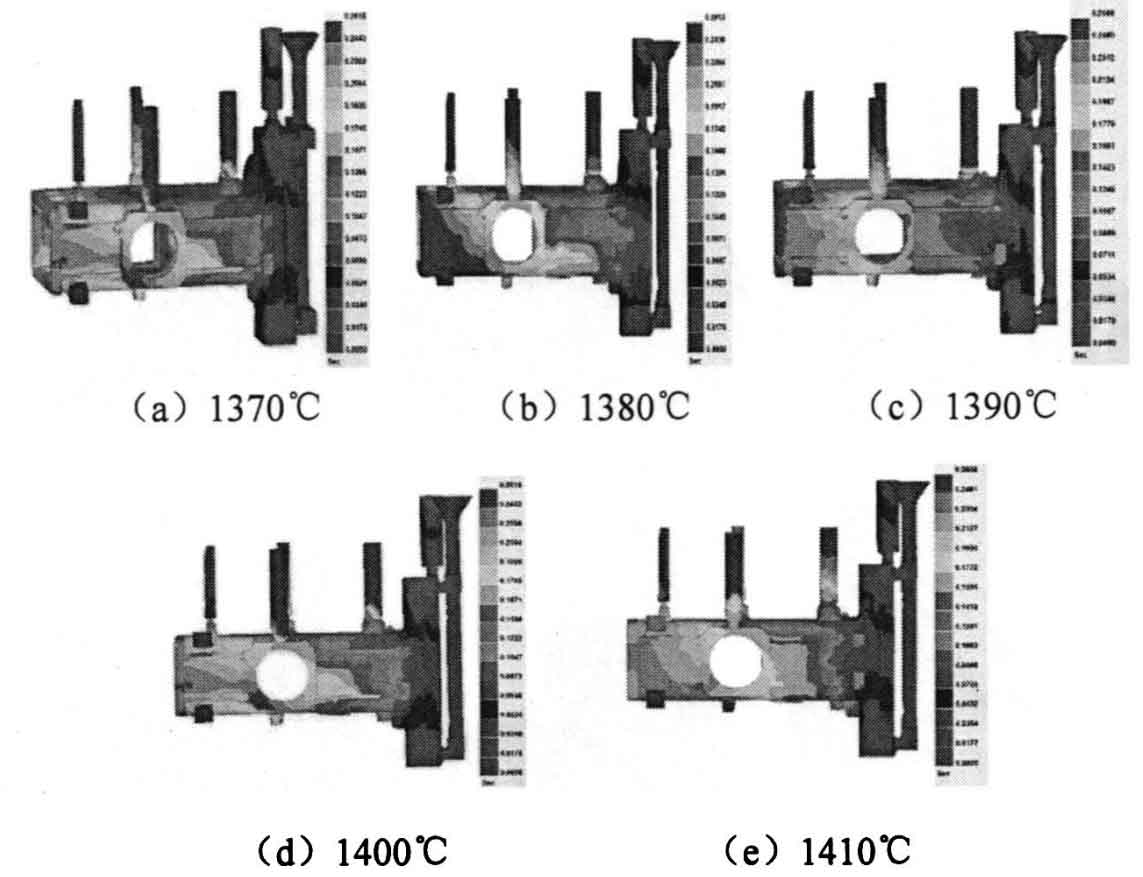

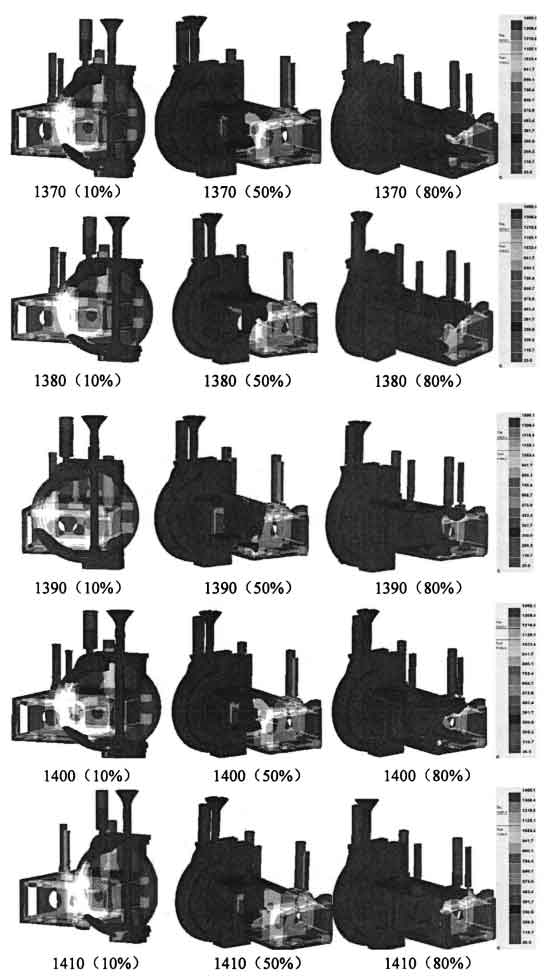

As shown in Figure 1, it is the filling time diagram of each part of the mold when different pouring temperatures are adopted. Through analysis, it is found that the pouring temperature has no obvious effect on the filling time of the mold, and the filling state of liquid metal is basically the same. According to the simulation results, under different pouring temperatures, the time of liquid metal filling the mold cavity is 0.2618s, 0.2613s, 0.2668s, 0.2618s and 0.2658s. It can be seen that the pouring temperature of liquid metal has little effect on the filling time. Fig. 2 is the filling state diagram of sand casting with 10%, 50% and 80% filling under different temperature conditions. According to the analysis of Fig. 2, it is found that there is no turbulence and air entrainment during the pouring process, and the temperature of molten metal in the mold basically does not drop after the filling is completed and remains at 1360 “C.

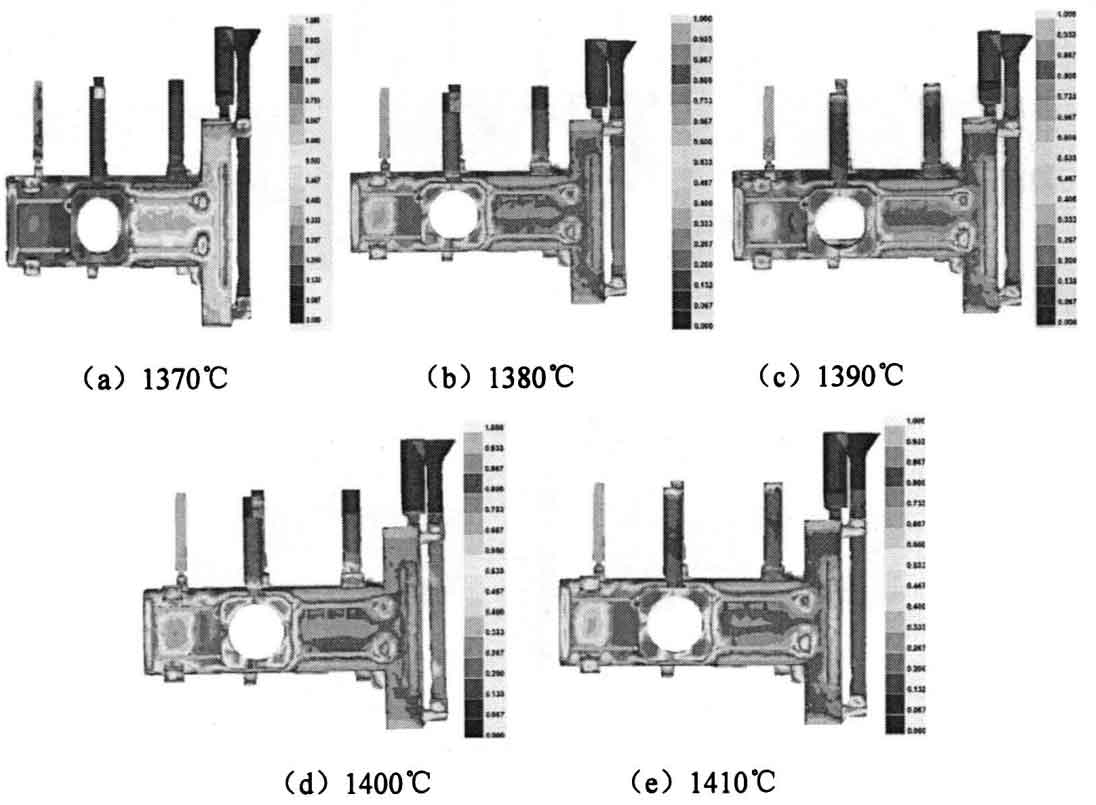

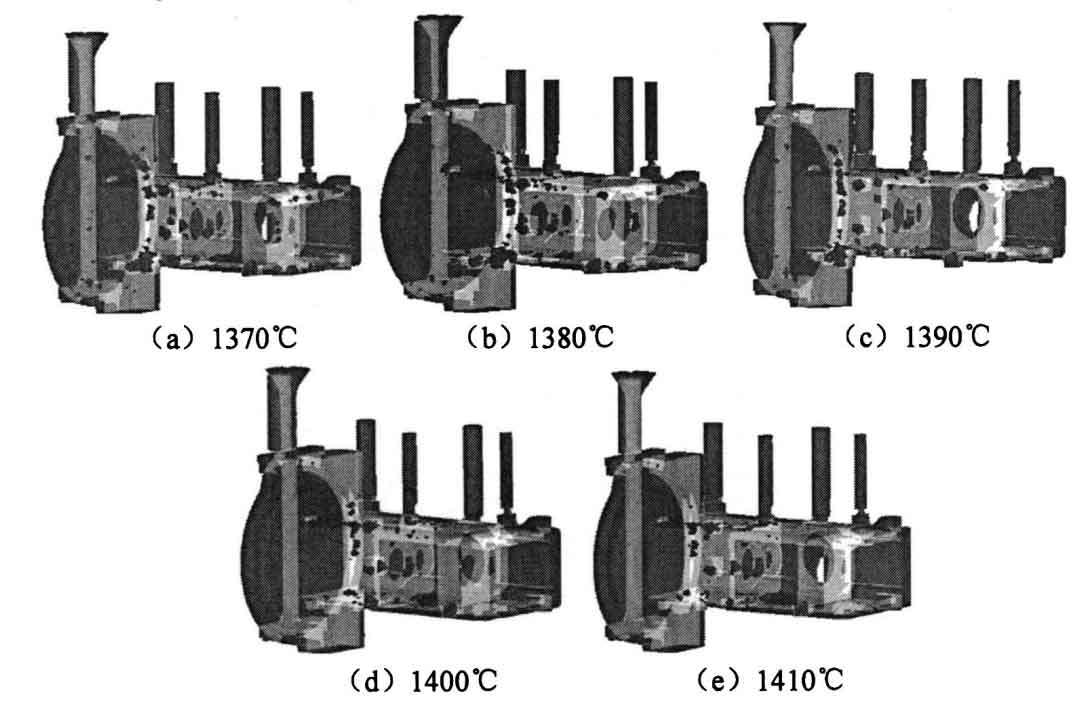

Fig. 3 shows the distribution of solid content in various parts of sand castings when the inner gate is closed at different pouring temperatures. The closing time of the inner gate is 18.23s, 20.667s, 23.285s, 26.143s and 27.643s, that is, the higher the temperature, the longer the time required for the inner gate to be closed. In general, the later the inner gate is closed, the more liquid metal the inner gate can provide for sand castings, and the less likely the sand castings are to have defects. It can be seen from Fig. 3 that at 1410 ℃, the sand casting shaft is installed at the boss, because of its large size, high internal temperature and low solid rate, which increases the possibility of shrinkage porosity and shrinkage cavity of sand casting to a certain extent. Therefore, it can be seen that the higher the pouring temperature is, the better.

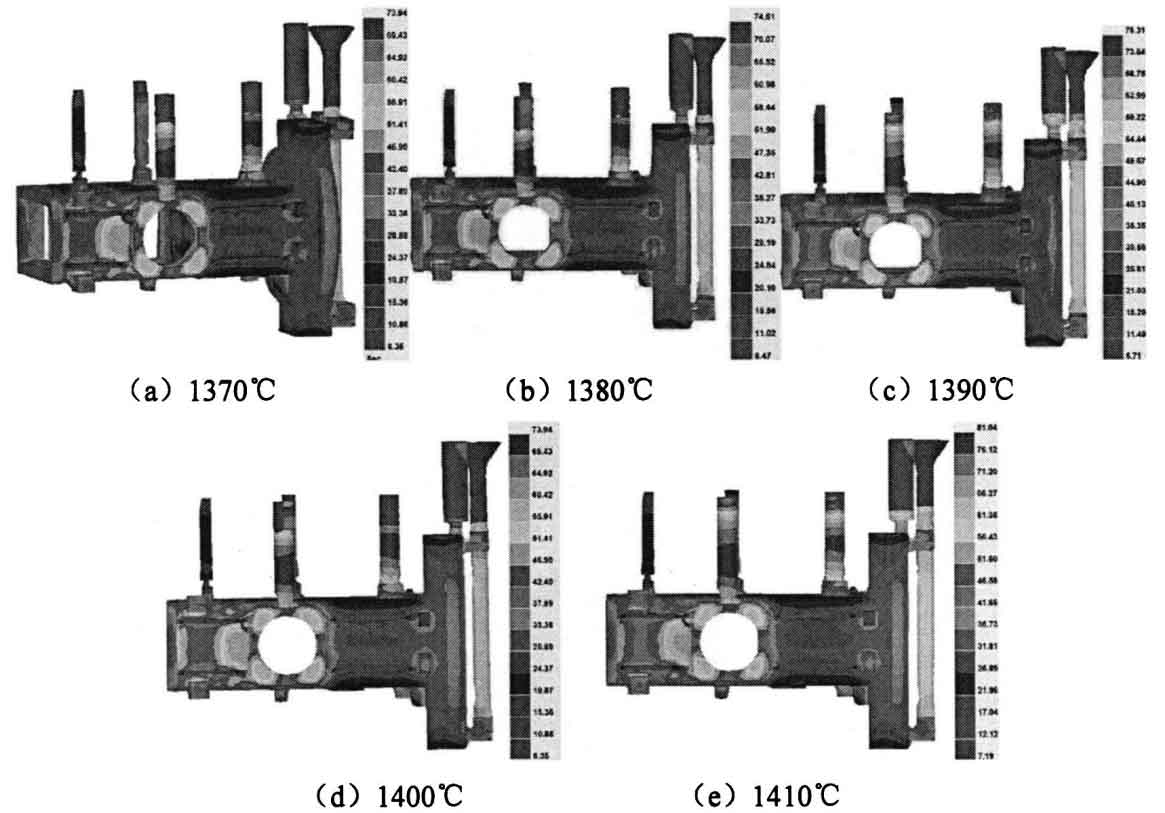

Fig. 4 shows the solidification time of the casting under different temperature conditions. The solidification time is g 73.94s, 74.61s, 78.31s, 80.94s and 81.04s. It can be seen that the solidification time increases first with the increase of temperature. Fig. 5 shows the distribution and size of shrinkage porosity and shrinkage cavity of sand casting after solidification at different pouring temperatures. It can be seen from Fig. 5 that the defects of sand casting mainly appear at the connection of flat plates and rectangular bosses on both sides, the hot joint of internal support plate and feeding riser. It can be seen from Figure 5 that when the pouring temperature is 1400 ℃, the shrinkage porosity and shrinkage cavity size of sand casting are the smallest. For example, the table shows the comparison of internal gate solidification time, total mold filling time, total solidification time and defects under different temperature conditions. It is found that the mold filling time first decreases and then increases with the increase of temperature, and the solidification time gradually increases with the increase of temperature.

Based on the above analysis, high pouring temperature is conducive to the completion of mold filling, but too high temperature is easy to cause oxidation. The influence of pouring temperature on the solidification process is mainly aimed at the feeding of liquid metal, that is, the length of time required for the closure of the inner gate and the solid rate of the thick part of the sand casting. Combined with the solidification and defects of sand castings and the production efficiency of sand castings, it is considered that 1400 is adopted. C pouring temperature is the most appropriate.

In the process of sand casting, the pouring temperature should be selected appropriately. The higher the liquid metal temperature, the better the fluidity and the easier the mold filling; However, if the temperature of molten metal is too high, it is easy to cause splashing of molten metal, oxidize the molten metal, produce oxidation inclusions, and reduce the mechanical properties of sand castings. If the liquid metal temperature is too low, it is easy to cause defects such as insufficient pouring and affect the feeding of sand castings. Therefore, the appropriate pouring temperature should be selected.

| Temperature (° C) | Total filling time (s) | Setting time of inner gate (s) | Total setting time (s) | Size of shrinkage porosity and shrinkage cavity |

| 1370 | 0.2618 | 18.23 | 73.94 | Maximum |

| 1380 | 0.2613 | 20.667 | 74.61 | Large |

| 1390 | 0.2668 | 23.285 | 78.31 | Middle |

| 1400 | 0.2618 | 26.143 | 80.94 | Minimum |

| 1410 | 0.2658 | 27.643 | 81.04 | Small |