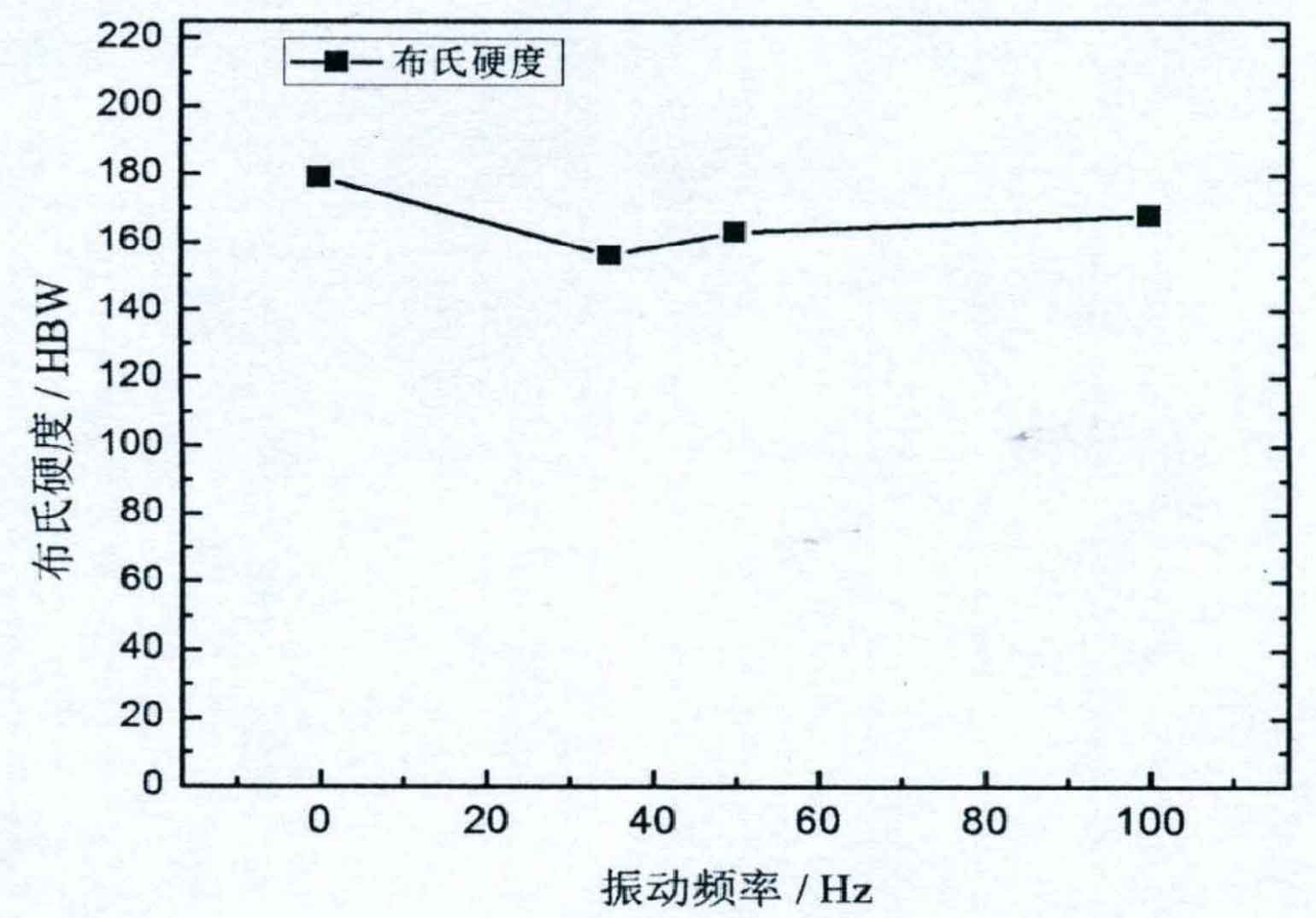

1.Effect on hardness

Figure 1 shows the change curve of Brinell hardness of nodular cast iron with vibration frequency. It can be seen from the figure that with the increase of coil vibration frequency, the Brinell hardness of nodular cast iron first decreases and then increases. The Brinell hardness of spheroidal graphite cast iron without vibration is the highest, which is 179hbs. The Brinell hardness of spheroidal graphite cast iron with vibration frequency of 35Hz is the lowest, which is 156hbs, which is 12.85% lower than that of spheroidal graphite cast iron without vibration.

Previous studies have shown that the hardness of nodular cast iron mainly depends on the matrix structure in cast iron. The hardness of nodular cast iron is determined by the pearlite content in cast iron and the pearlite sheet spacing. The higher the pearlite content and the smaller the sheet spacing, the higher the hardness of nodular cast iron, and vice versa. It can be seen from the test results that the content of pearlite is the highest in the lost foam casting ductile iron without vibration, which is the fundamental reason for the maximum hardness value. When the vibration is applied to the ductile iron lost foam casting, the pearlite content in the cast iron decreases. When the vibration frequency is 35Hz, the pearlite content in the ductile iron is the minimum and the hardness value is the minimum. If the vibration frequency continues to increase, the pearlite content in nodular cast iron increases and the hardness value of cast iron increases.

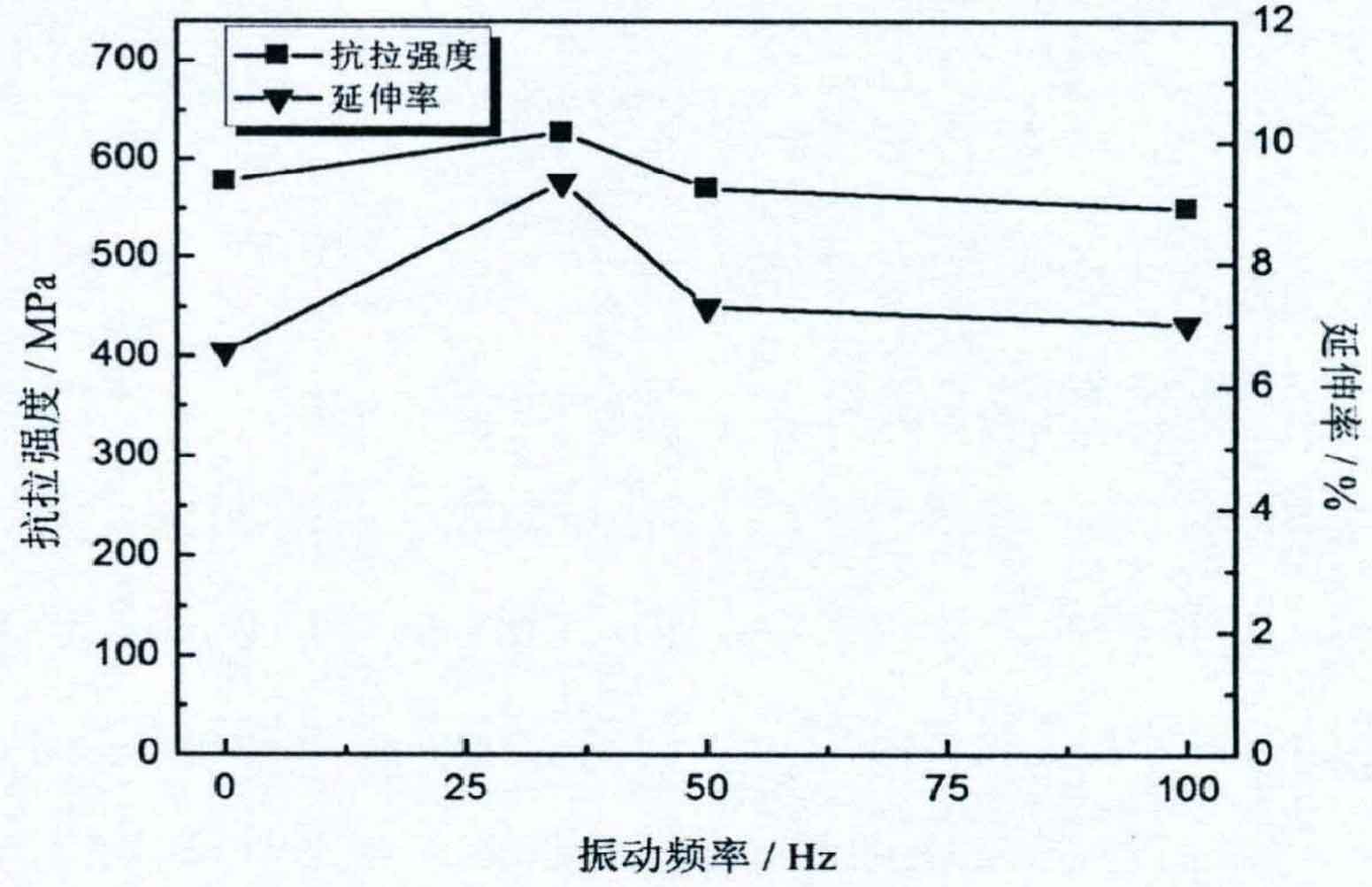

2.Impact on mechanical properties

The figure 2 shows the variation curve of mechanical properties of ductile iron in lost foam casting with vibration frequency.

It can be seen from the figure that when the amplitude is 3mm and the vibration frequency increases from 0Hz to 35Hz, the pearlite sheet spacing is small, and there is more granular pearlite in the structure of nodular cast iron. The tensile strength and elongation of nodular cast iron are large, with the maximum values of 626.65mpa and 9.35%, which are 4.82% and 42.53% higher than that of 577.82mpa and 6.56% of the non vibrating lost foam casting nodular cast iron. When the vibration frequency increases to 50Hz, although granular pearlite still exists in nodular cast iron, the plate spacing of pearlite increases, which increases the splitting effect on the matrix and reduces the tensile strength and elongation of the alloy. When the vibration frequency is further increased to 100Hz, the flake spacing of pearlite is further increased, and the graphite morphology becomes worse, which reduces the tensile strength and elongation of nodular cast iron.

The mechanical properties of nodular cast iron mainly depend on the matrix structure of nodular cast iron. At the same time, the shape, size, quantity and distribution of graphite balls also play an important role in the mechanical properties of nodular cast iron.