1) Establishment of 3D solid model

There is no solid modeling function in ProCAST software, and the three-dimensional solid model of sand casting frame is completed in Pro / E. After the completion of solid modeling, the three-dimensional model of casting molding system including riser system, core and sand mold also needs to be established. In the actual production, the sand casting frame is one piece per box. According to the sand casting process scheme, the assembly of casting, riser, cold iron and sand box is established in Pro / E to form a complete sand casting system. In order to reduce the amount of simulation calculation, according to the symmetrical characteristics of the sand casting frame about the central surface, one-half of the sand casting process model is taken for solid modeling in the actual simulation analysis.

2) Finite element mesh generation

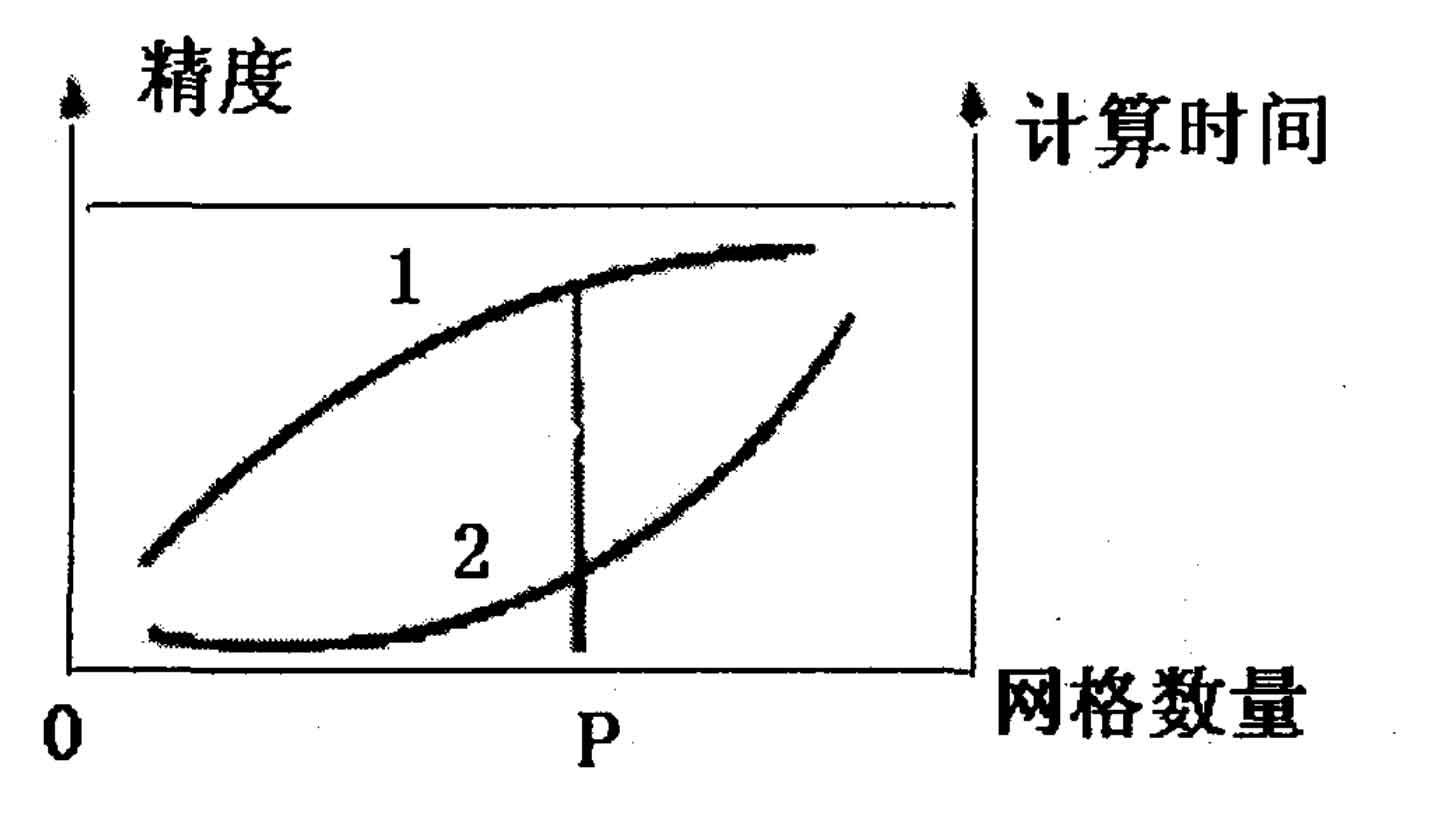

The mesh generation of finite element surface is completed in Pro / E. Meshing format is an important link in establishing finite element model. It involves many problems. It requires a large amount of work to establish a correct and reasonable finite element model. The divided finite element mesh has a direct impact on the simulation calculation accuracy and calculation time. And calculation time and meter

The relationship between the calculation accuracy and the number of grids is shown in Figure 1. It can be seen from the figure that when a certain number of grids are used, it can obtain higher calculation accuracy while consuming less calculation time.

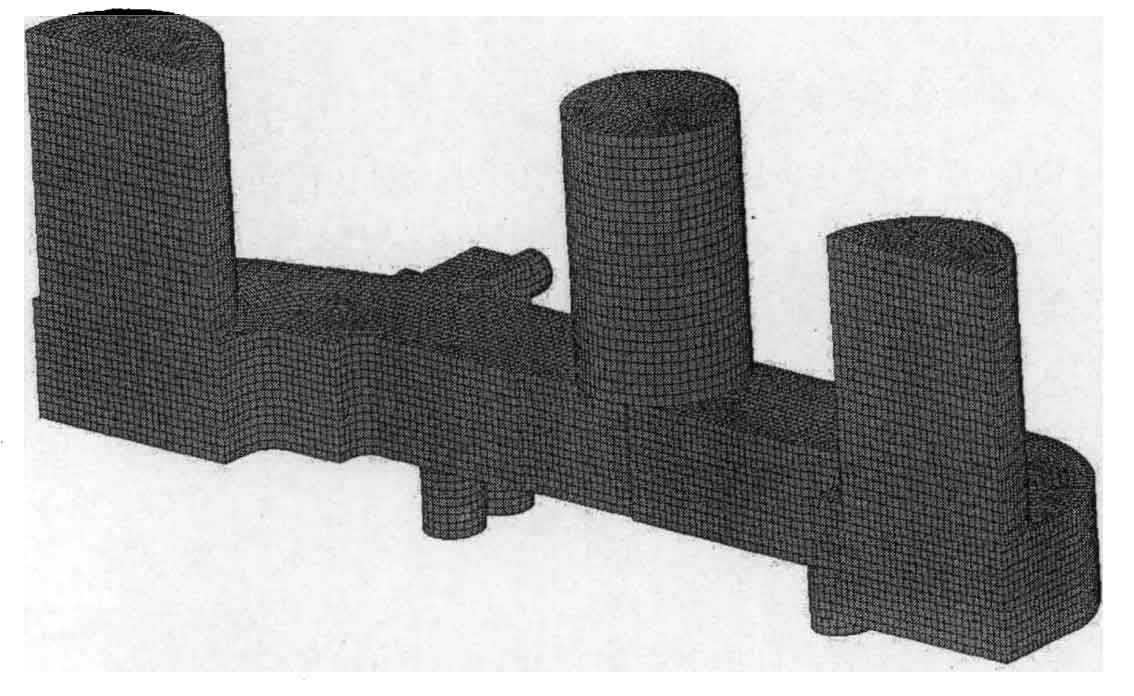

In order to obtain a high-quality mesh, the model is simplified in the modeling process. For example, when it has little impact on the simulation results, delete some sand casting fillets with small radius, forcibly modify the sharp corners of the model, etc., which not only ensures the effectiveness of the solid model, but also speeds up the later simulation calculation speed. The interface of ProCAST was discussed in detail before. Due to the particularity of the model, the finite element mesh generation was selected in Patran.

When meshing, hexahedral element mesh with high precision is selected. Different grid densities are set for different parts of sand castings. For some special parts, such as near the fillet, a smaller grid density is used to improve the analysis accuracy. Import the out format volume grid file into ProCAST first, generate p.dat file, and get the best result in meshcast Mesh format grid file. The finite element model of sand casting frame is shown in Figure 2. The model contains 84503 volume grids and 94758 nodes.