The filling form of regular flat plate model is divided in the front. In actual production, the structure of lost foam casting parts varies greatly, and the filling form of molten metal is also different from that of regular flat plate model. In the experiment, a simple shaped part – groove sample was selected to study its filling shape.

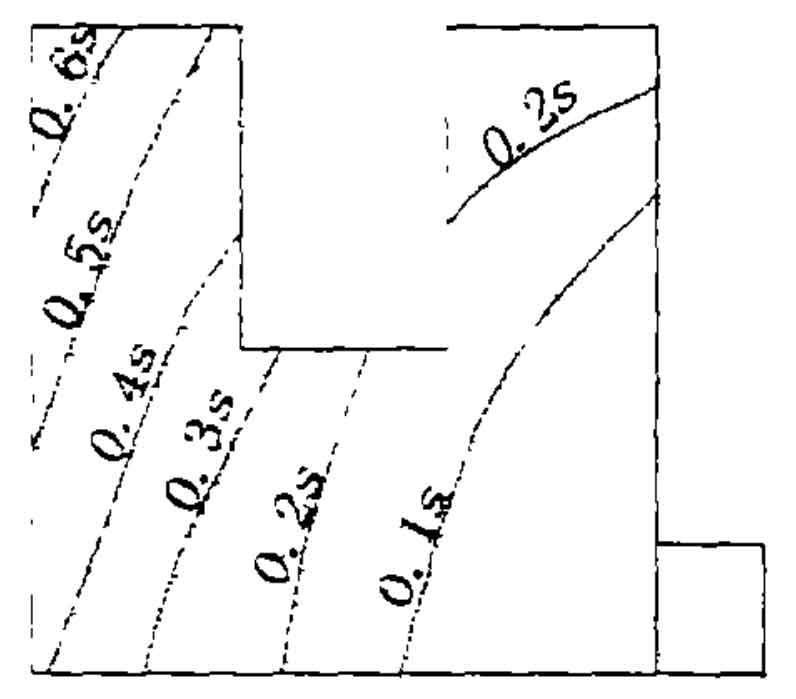

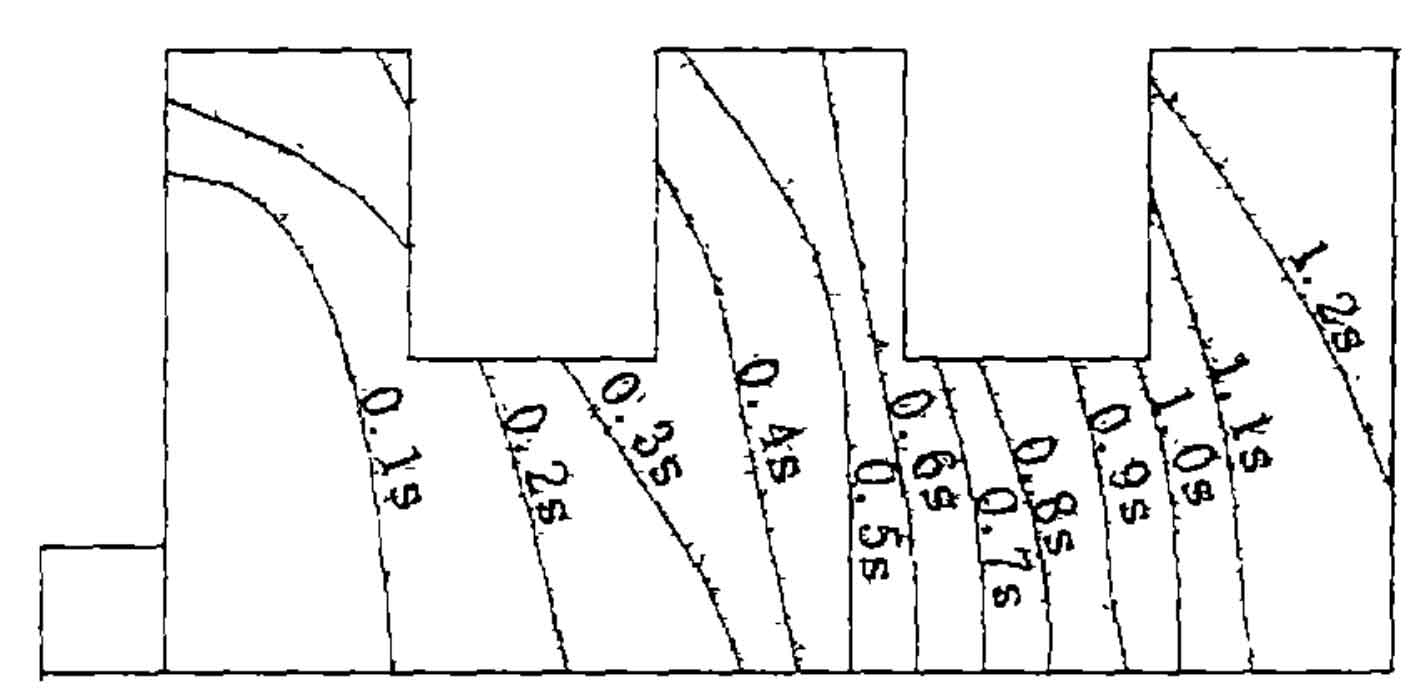

As shown in Fig. 1, the groove width of the model is 40mm, the groove depth is 50mm, the groove sidewall pattern is 40mm wide, and the overall dimension of the model is 120mmx100mm x20mm; The model shown in Fig. 2 is of double groove shape. The outline dimension of the model is 200mmx100mmx20mm. The outside of the model is coated with a coating with permeability K0 = 30.78. The model is placed in the sand box. The height of the sprue is 200mm. The ingate is introduced from the side and poured under the conditions of vacuum negative pressure of – 400mmhg and pouring temperature of 1400 ℃. From the isochronous curve, it can be seen that the filling shape of molten metal in lost foam casting is basically the same under the condition of different groove numbers.

At the beginning of lost foam casting filling, the isochronous curve is sparse, and the filling speed of molten metal is fast. With the filling process, the isochronous curve is relatively dense, and the filling speed of molten metal becomes slow. It takes 0.6s to fill the single groove model, 0.62s to fill the same length part of the double groove model and 1.34s to fill the whole model.