Product Introduction

The stainless steel volute is made of ZG12Cr18Ni9Ti, with the composition control shown in . The single weight of the casting is 3.2 t, with a maximum size of 3800 mm and a wall thickness of 20 mm, which is a typical thin-walled structural part. As shown in Figure 1, there are 30 partitions in the volute cavity, with a wall thickness of 20 mm and a height of 200 mm. The partitions are connected to the upper and lower end faces to form a hot spot. Based on these characteristics, the complex and unevenly thick volute part with an integral casting process is prone to deformation and casting defects. This requires that the design of the casting process not only focus on the feeding of the hot spot, but also take into account smooth filling, slag removal and degasification.

Production process

According to the symmetrical structure of the casting, with the characteristics of multiple control valve flanges and mounting bosses, the above-mentioned parts are made into movable blocks in the mold design.The same wooden model plate can be used to complete the modeling of the upper and lower sand boxes. The steel cone is used for positioning the sand mold, with a negative parting of 3 mm. The overall shrinkage rate of the molten steel is designed to be 2.5%, with the inlet and outlet flanges of the volute designed to have a shrinkage rate of 1.0% and a machining allowance of 15 mm. The sand core mass is estimated to be about 3 t based on the density of the bead sand of 2.0 g/cm3. It is difficult to make an integral sand core, so it is changed to a 1/2 sand core, with the symmetrical center plane above and below as the parting surface, and sawdust and straw ropes are added in the middle to increase the concession. In addition, due to the large span size of the sand core, a reinforced core structure with steel bars welded to prevent deformation and drift during casting process is designed.

Casting process

In order to shorten the pouring and filling time and reduce defects such as slag and pores in large thin-walled castings, the process runner is designed according to the double-ladle pouring method, and at the same time,To prevent sand from rushing into the casting during pouring, ceramic pipes are used to arrange the sprues, which also facilitate the flow of molten steel and the filling of the casting, avoiding inclusion defects. As shown in Figures 3 and 4, six risers are evenly distributed on the flanges, with supplementary risers arranged on the inlet and outlet large flanges, and an air vent rod arranged at the high point of the outer shape of the upper box. The sprues are designed on both sides of the parting surface along with the casting test bar. Considering the large volumetric contraction of molten steel, open pouring system is used for casting, with a section ratio of ∑S vertical:∑S horizontal:∑S internal=2:3:4 for each unit. Two schemes are designed for the layout of the runner and sprue.

(1) In Scheme 1, the process yield is 63.33%. A layer of internal runners is arranged on the parting surface, with ϕ120 mm and ϕ90 mm ceramic tubes used for the runner and internal runner, respectively, as shown in the figure.

(2) The process yield of scheme 2 is 60.24%, which is based on scheme 1 and adds a layer of internal runner at 1/2 of the lower box cavity to form a two-layer stage.

The ladder-type internal runner can ensure good filling and reduce the temperature difference at the bottom, as shown in the figure.

(3) In order to improve the yield of castings, a easy-to-cut riser block was used, as shown in the figure. The mixture of 80% of silica sand, 15% of resin, 4% of curing agent, and 1% of waste steel shot (ϕ≤0.1 mm) was mixed, and the mixed sand was placed in a self-made mold for 5-10 minutes to harden and form; when the sand buried height was When the degree of cooling is the same as the height of the easy-to-cut riser, connect the position of the liquid inlet at the bottom of the heating and insulation riser to the top of the set-up sand mold easy-to-cut riser base. Using this method, while improving the yield of castings, the original cutting time for each riser can be reduced from 5 minutes to 1 minute.

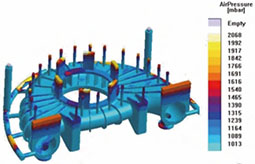

Process simulation analysis and optimization design

Set parameters in the CAE software according to the actual pouring process, where the mold material is resin sand, and the heat transfer coefficient between the casting and the sand box is The heat transfer rate is 700 W/(m2·K), the pouring temperature is set to 1600 ℃, the initial sand mold temperature is 20 ℃, the pouring time is 93 s, the heat transfer method is air cooling, the external heat exchange conditions are convection and radiation, and the permeability of the sand mold is considered. Other parameters are selected by default from the software.

Based on the results of numerical simulation of filling, solidification, and pressure changes, the final casting process plan was determined to be plan 1 after comprehensive analysis. At the same time, in order to It is possible to eliminate casting defects, increase the feeding capacity of risers, and increase the compactness of castings by adding local external chill, internal chill, and chromite sand arrangements to prevent casting defects such as cracks and shrinkage cavities.

Molten steel smelting and composition control

The total weight of the molten steel is 5.4-5.6 t, which requires simultaneous smelting with 2 sets of 3 t electric furnaces. The pouring temperature is controlled at 1590-1620 ℃, and the ladle is baked above 800 ℃. After pouring, carbon-free insulation agents are added for covering. After 48 hours of pouring, the sand is removed from the box. When smelting titanium-containing stainless steel, due to the lively titanium element, the yield is 40%-50%, and it is easy to react with nitrogen during smelting and solidification to form harmful phase TiN. TiN not only affects the fluidity of the molten steel, but also easily forms slagging and other defects on the surface of the casting. Therefore, in order to reduce the nitrogen content in the molten steel, the proportion of stainless steel pouring and riser return materials should be reduced during smelting, controlled within 20%. The titanium alloy selects 70 Ti-Fe, and the steel is discharged immediately after adding 2-3 minutes in the furnace. Before adding Ti-Fe, it should be deoxidized by ferrosilicon and manganese silicate calcium.

Production validation

The production uses alkaline phenolic resin bead sand molding and core making, with stainless steel alcohol-based coating applied to the sand mold cavity. The pouring temperature is controlled at 1600-1610℃, and the sprue and risers are cut after the stainless steel volute casting is formed. After testing, there are no casting defects such as cracks, pores, shrinkage cavities, and slag inclusions that affect product quality inside the casting. As shown in the figure, the dimensions of the casting after mechanical processing meet the requirements of the drawing. The tensile samples taken from the furnace test bar are tested for their mechanical properties.The tensile strength was measured to be 490 MPa, the yield strength was 215 MPa, the elongation was 28%, and the section shrinkage was 35%, meeting the design requirements. In summary, this process measure is effective and correct, and can meet the requirements of mass production of products.

Epilogue

Based on the structural characteristics of the stainless steel volute casting and the calculation results of the CAE simulation software, an open pouring system was designed, and ceramic tube distribution was used to achieve the The placement of the sprue reduces sand inclusion and other defects. By rationally setting up risers, chills, chromite sand, and appropriate pouring temperatures and filling speeds, the complete shape and quality of the spiral case casting that meets design requirements are finally produced.