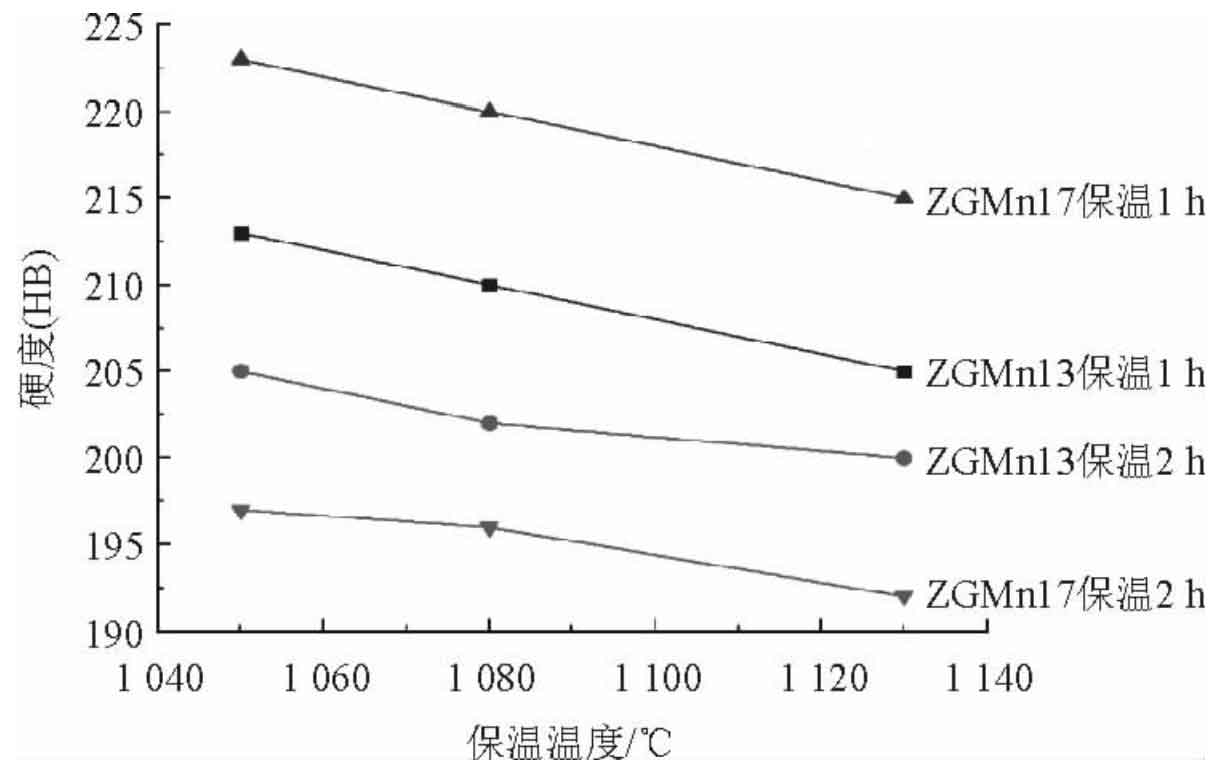

The figure shows the hardness of ZGMn13 and zgmn17 under different water toughening treatments. It can be seen that the hardness (HB) of ZGMn13 high manganese steel and zgmn17 ultra-high manganese steel lost foam casting lining plate is the highest, 213 and 223 respectively, when it is kept at 1050 ℃ for 1H. This is because a small amount of carbide has not yet dissolved into the matrix at this temperature, so the hardness is higher. When the temperature rises to 1080 ℃, the grains of the two grow completely and the carbides dissolve, so the hardness decreases. When the temperature rises to 1130 ℃, the grains of the two products become coarse due to overheating, resulting in further reduction of hardness. The hardness (HB) of as cast high manganese steel and ultra-high manganese steel is high, about 230 and 245.7 respectively. It was found that the hardness decreased after water toughening treatment. The hardness of ultra-high manganese steel lost foam casting liner after 1h heat preservation is higher than that of high manganese steel lost foam casting liner, but it is lower after 2H heat preservation. This is because although the water toughening treatment has the effect of solid solution strengthening on the sample, the effect of solid solution strengthening on the hardness is far less than that of carbides in as cast steel. Therefore, after the water toughening treatment, the hardness of the sample decreases significantly with the decrease of carbides content. Generally, the carbide content is directly proportional to the hardness. When holding for 1h, because the carbide of ultra-high manganese steel is higher than that of high manganese steel, the hardness is higher than that of high manganese steel lost foam casting liner; When holding for 2h, the lining plate of lost foam casting appears overheating and decarburization reaction occurs in the grain. Because the carbide precipitated from ultra-high manganese steel is much higher than that from high manganese steel, the hardness is lower.

In conclusion, the hardness of high manganese steel and ultra-high manganese steel LFC lining plate is the highest when it is kept at 1050 ℃ for 1h, but some carbides in the structure lead to poor plasticity and toughness, so it is not suitable for ball mill. When holding at 1080 ℃ for 1h, the carbides are completely dissolved, which improves the plastic toughness of the steel and ensures that the liner plate of lost foam casting will not undergo brittle fracture under strong impact. At the same time, because the hardness is not significantly reduced, the lost foam casting liner has good deformation resistance and long service life.