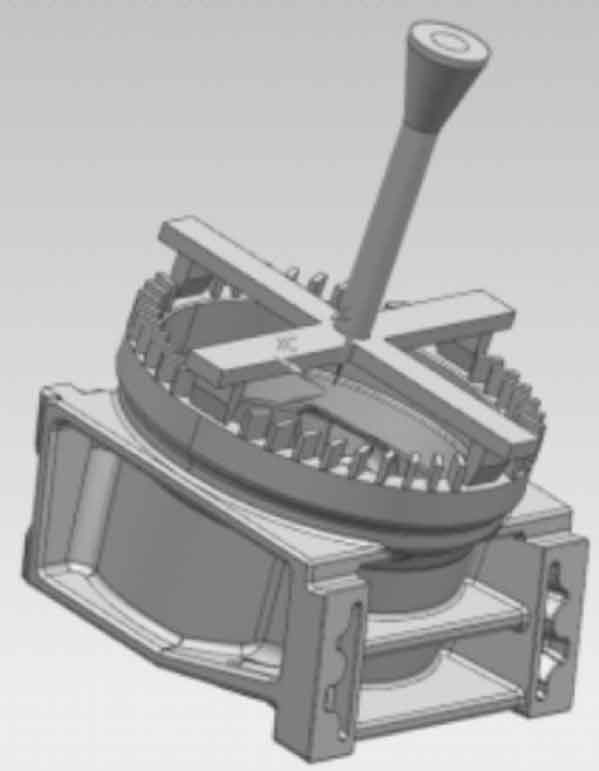

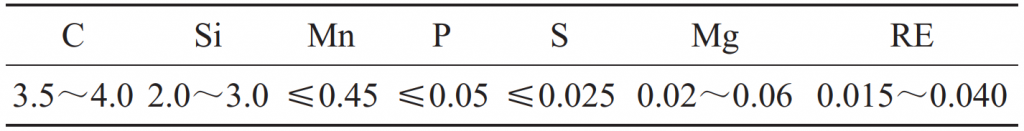

The combination process of lost foam casting nodular cast iron reducer shell is shown in the figure. The design process allowance of end face is 4 mm, the tapping temperature is 1580 ~ 1600 ℃, the pouring temperature is 1370 ~ 1440 ℃, the pouring negative pressure is -0.04 ~ -0.06 MPa, and the negative pressure holding time is 900 s. The chemical composition of reducer shell is shown in the table. The mechanical properties of Y-shaped sample meet the requirements of QT450-10, The spheroidization rate of grade 2 ~ 3 also meets the technical requirements of lost foam casting nodular cast iron reducer housing, but there are shrinkage porosity, shrinkage cavity, inclusion and other defects in the production of lost foam casting nodular cast iron sample of reducer housing.

In the process of small batch production, there are inclusions on the end face of the reducer shell and shrinkage defects at the geometric hot joint.