The test results are shown in the table:

| Pouring position | Total mold filling time (s) | Average filling speed (cm/s) |

| Side pouring | 0.87 | 22.99 |

| Intermediate pouring | 1.13 | 17.78 |

| Bottom pouring | 5.37 | 3.7 |

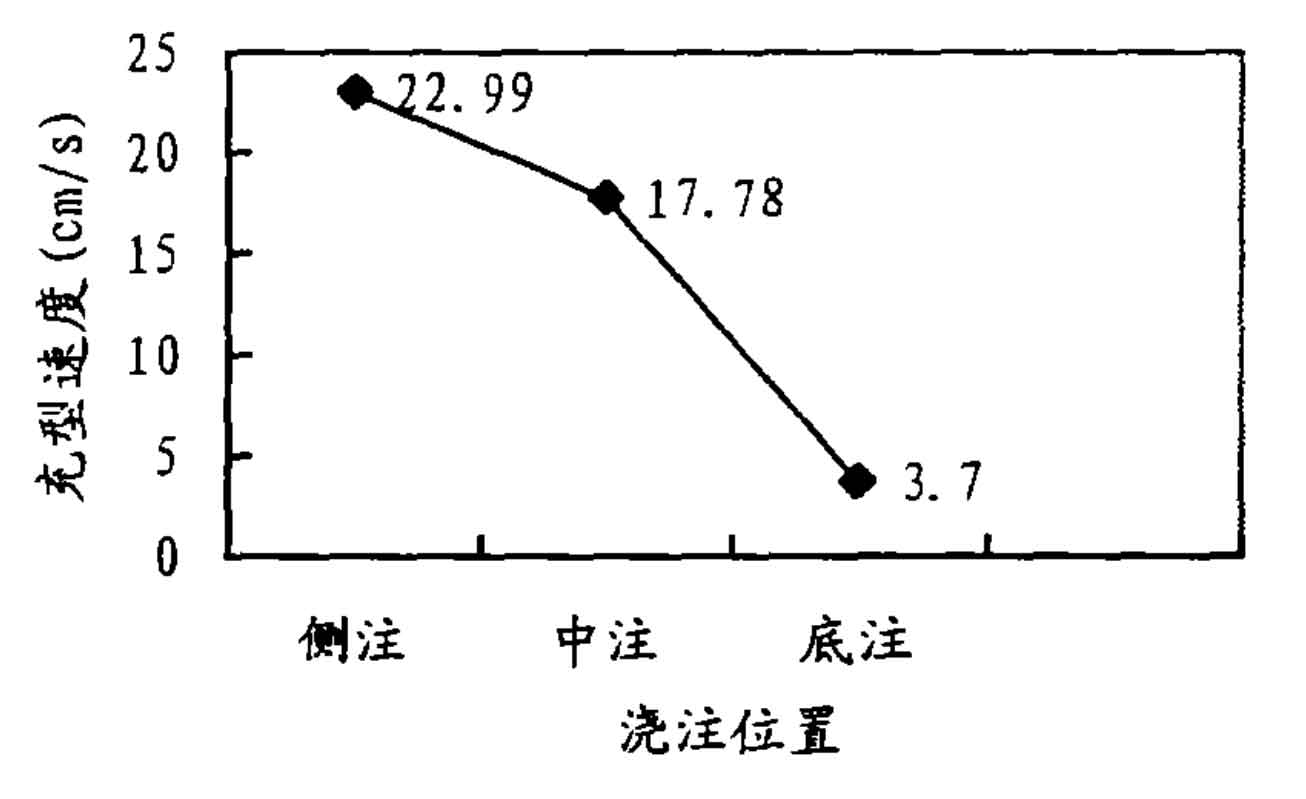

As shown in the figure, when other test conditions are the same, the relationship between the average mold filling speed of liquid metal in lost foam casting and the pouring method is shown. The filling speed is the fastest at 22.99cm/s during side injection; The filling speed is 17.88cm/s; The mold filling speed of liquid metal in lost foam casting during bottom injection is the slowest, which is 3.7cm/s. The mold filling speed of liquid metal in lost foam casting during side injection is 5.21 times that of liquid metal during bottom injection. When the initial static head is equal, with the filling process of lost foam casting, the gasification of the model disappears, and the change of the effective static head of liquid metal is related to the pouring method.

Under certain conditions such as pouring temperature, vacuum negative pressure and coating permeability, it can be considered that the gasification decomposition speed of the pattern is the same as the speed of gasification products escaping from the mold, and the air gap pressure at the interface between liquid metal and pattern does not change with different pouring methods. The driving force of liquid metal filling in lost foam casting depends on the effective static head. Under different pouring methods, liquid metal has different filling acceleration.

During the bottom injection, the effective static head of the liquid metal decreases with the filling process. During the side injection, the liquid metal maintains a relatively constant effective static head. Therefore, during the bottom injection, the liquid metal filling acceleration is the smallest, and during the side injection, the liquid metal filling acceleration is the largest. From the perspective of the average filling speed of liquid metal, the order of filling speed of liquid metal in lost foam casting is that side injection is the fastest, medium injection is the second, and bottom injection is the slowest.