1. Production conditions of Lost Foam Casting Thin-wall gray cast iron gearbox shell

The production conditions and parameters of Lost Foam Casting Thin-wall gray cast iron gearbox shell casting are as follows:

(1) Sand content: more than 40% of the original mesh, accounting for 0 ~ 3% of the original mesh;

(2) Sand mold parameters: coating thickness 1.0 ~ 1.5 mm, moisture content amount ≤ 1%;

(3) Sand box structure: sand box size 2 050 mm × 1 500 mm × 1 300 mm, with air guiding device on five sides, vacuum negative pressure source on the bottom, vacuum negative pressure production line and 70 sand boxes;

(4) The teapot bag is poured by the automatic pouring machine, and the maximum pouring mass of a single bag is 2100Kg.

2. Introduction of Lost Foam Casting Thin-wall gray cast iron gearbox shell

The specific parameters of three kinds of gearbox shells used in large agricultural machinery of a Japanese company are as follows.

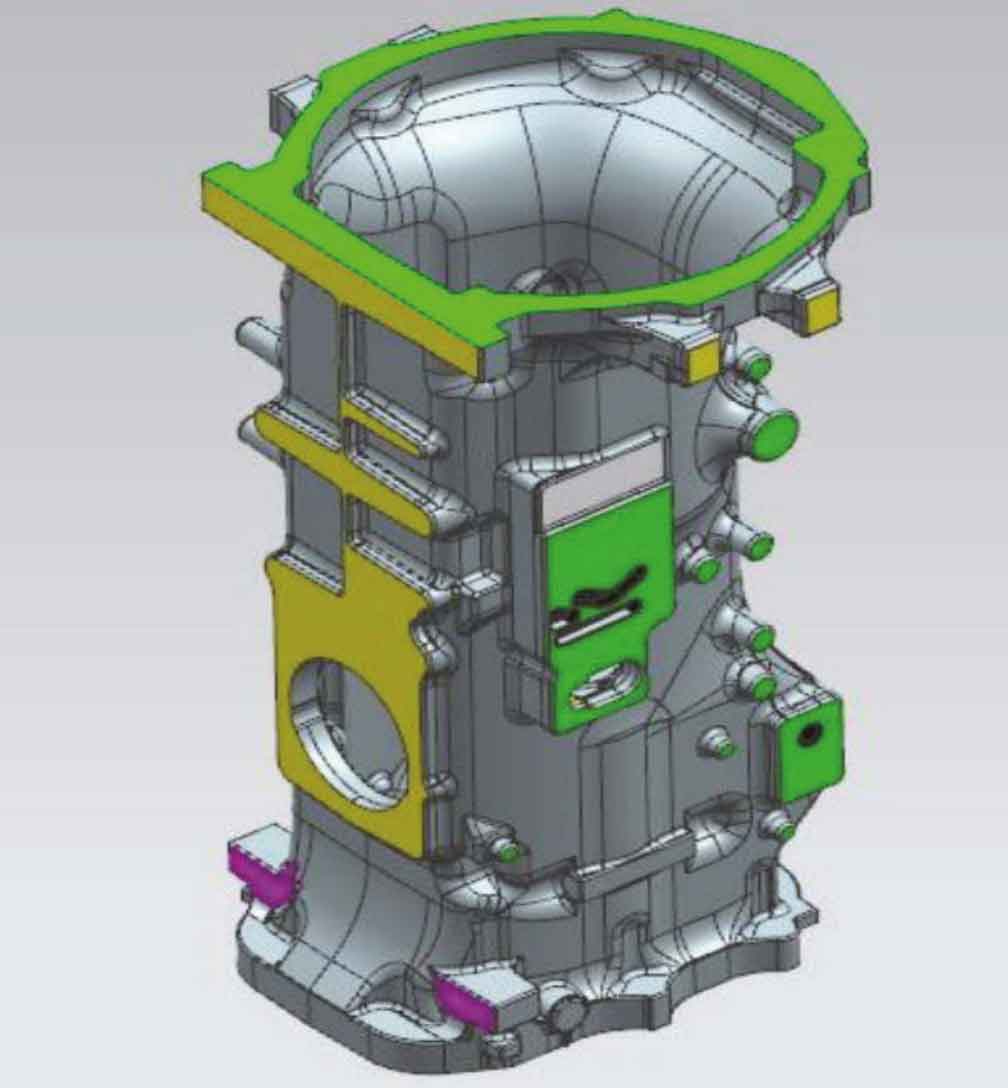

Gearbox housing a: the specific shape is shown in Figure 1. The material is HT300. The contour dimension of the Lost Foam Casting Thin-wall gray cast iron gearbox housing casting is 780 mm × 450 mm × 440 mm, the main body wall thickness is 5 ~ 6 mm (except the upper and lower flanges and perforated umbilicus, the wall is basically uniform), and the single piece mass of thin-wall gray cast iron gearbox shell cast by lost foam casting is 100 kg.

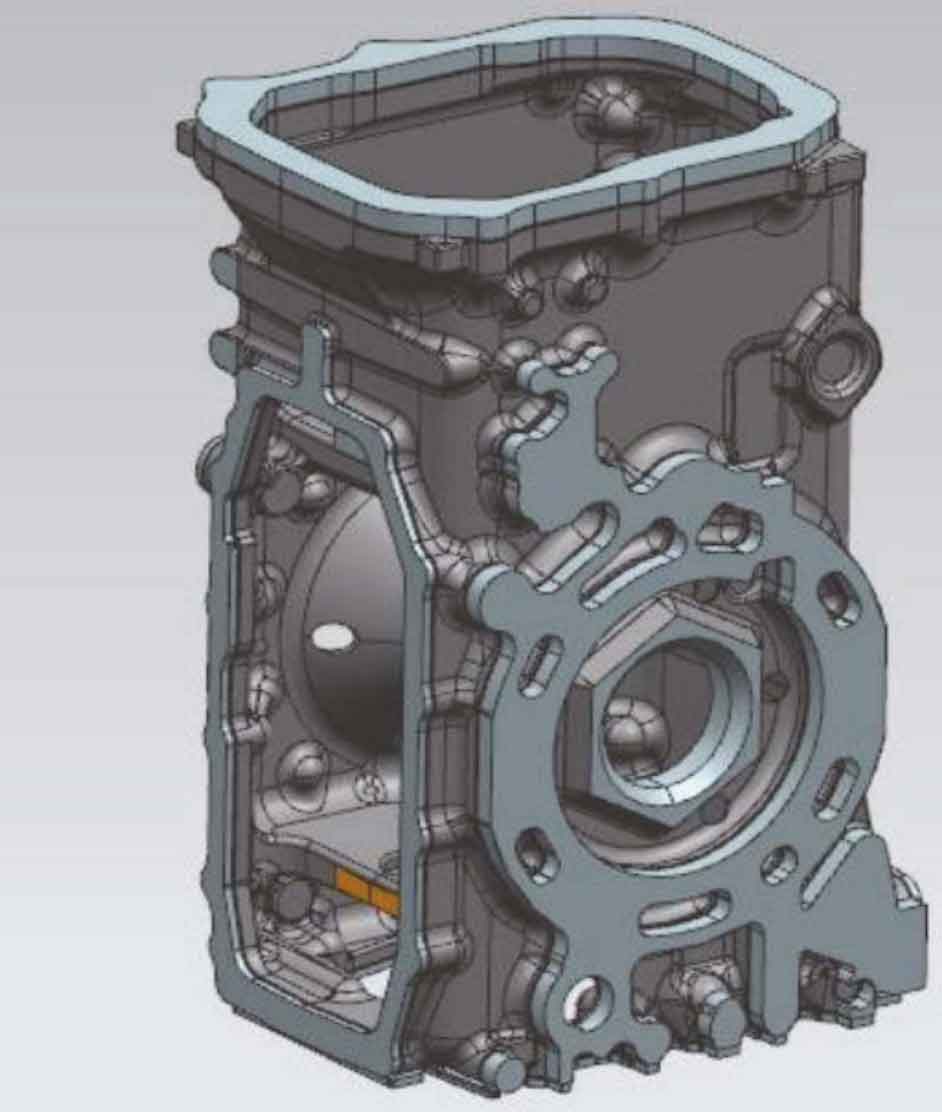

Gearbox housing B: the specific shape is shown in Figure 2. The material is HT300 and the outline dimension is 680 mm × 320 mm × 245 mm, the main body wall thickness is 6 ~ 7 mm (except the upper and lower flanges and perforated navel, the wall is basically uniform), and the single piece weight is 100 kg.

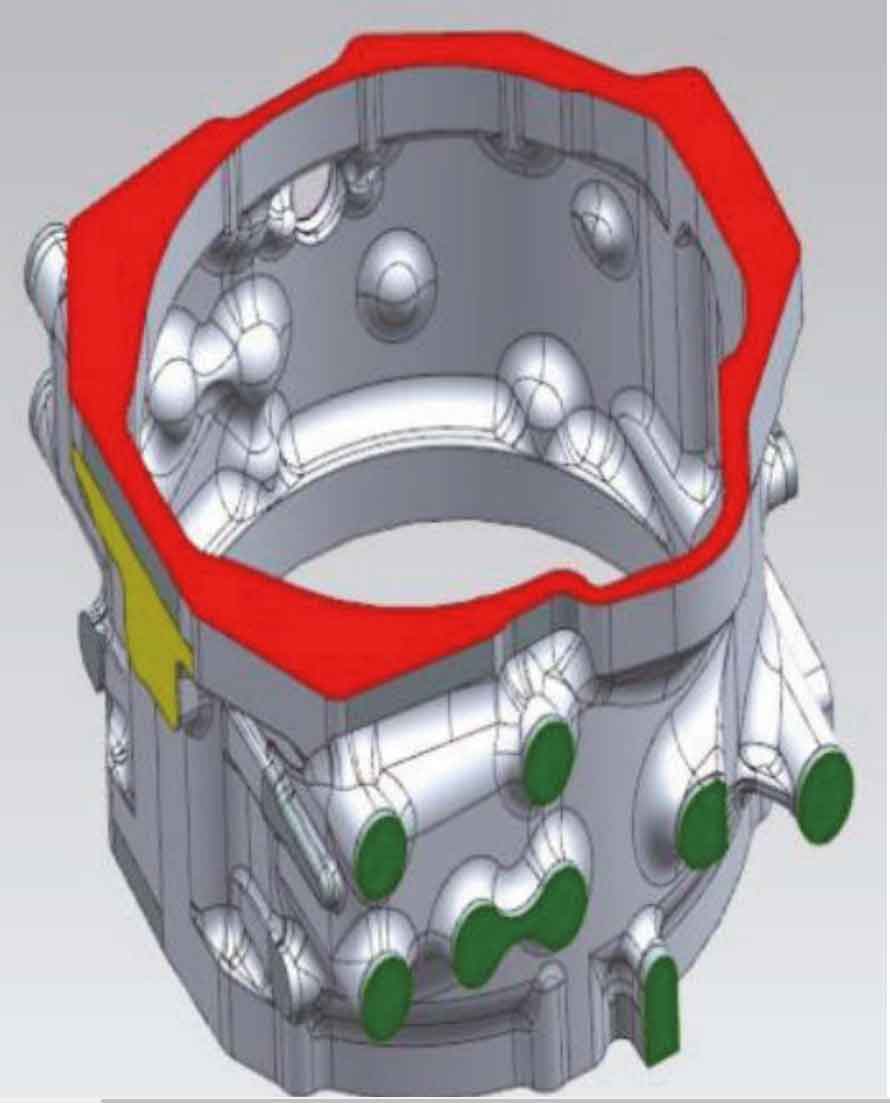

Gearbox housing C: the specific shape is shown in Figure 3, and the outline dimension is 440 mm × 420 mm × 380 mm, main body wall thickness of 5 ~ 6 mm (basically uniform wall except for upper and lower flanges and perforated navel), single piece mass of 68 kg.

The common feature of three kinds of lost foam casting thin-wall gray cast iron gearbox shell castings is that the overall wall thickness is 5 ~ 7 mm, and the hydraulic leakage test of 3 kg is required. Because the sand box used in factory production is relatively large, considering the factors of production efficiency and cost, the series pouring process of one box and multiple pieces can only be adopted, which is more difficult to produce.

3. Quality problems of Lost Foam Casting Thin-wall gray cast iron gearbox shell

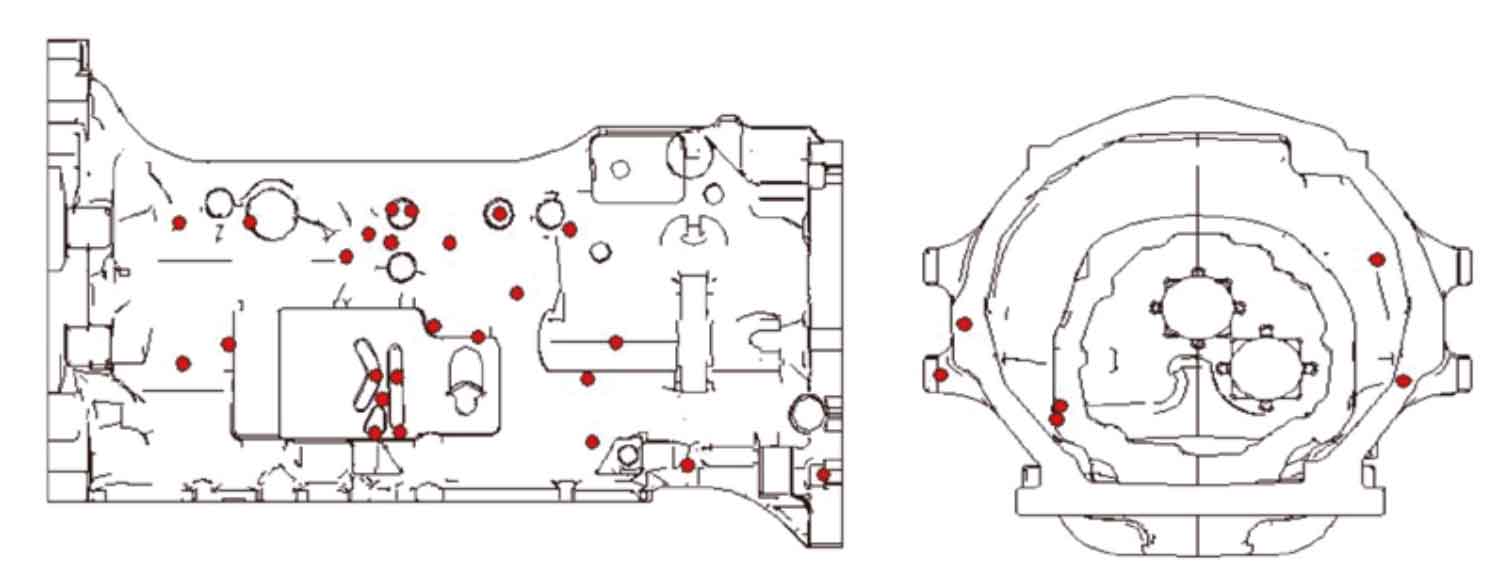

The main quality problems in the previous rounds of production of three kinds of gearbox shells are: the hydraulic test is unqualified, and Figure 4 shows the superposition diagram of gearbox shell a defects (superposition of defects of 30 scrapped parts); The exposed slag inclusion defects and cold shut defects of thin-wall gray cast iron gearbox shell casting in lost foam casting are shown in Fig. 5.