Titanium alloy has low density, high strength and good corrosion resistance, and is widely used in aerospace, naval and other fields. Titanium alloy has a unique silver gray, and has a good gloss after polishing. It is also suitable for the production of sports equipment. Investment casting, as a near-net forming casting process, can produce titanium alloy castings with complex shape and smooth surface, which is suitable for the production of titanium alloy castings. The numerical simulation technology can simulate the flow field, temperature field and stress field of the casting filling and solidification process, predict the distribution of shrinkage porosity and residual stress by simulating and analyzing the gating system before production, optimize the casting process, reduce the “trial and error cost” in production, and improve the economic benefits of enterprises.

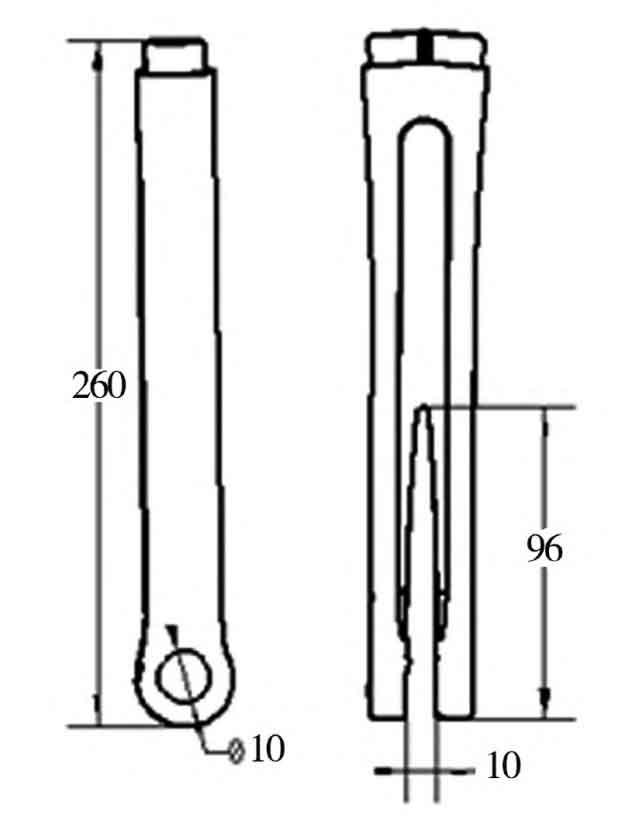

In the experiment, the technology of a kind of rod titanium alloy casting was studied by numerical simulation technology, and the first production qualification rate of rod titanium alloy casting was improved. The structure of the rod titanium alloy casting studied in the test is shown in the figure. The ratio of the length to the width of the rod is 9.3 ∶ 1. The wall thickness at the end of the rod is relatively uniform, but there is a large wall thickness ratio at the connection between the opening root and the rod, with the wall thickness ratio of 10.5 ∶ 1. The technical requirements are: the material is ZTC4, φ The 10mm hole is the processing part, and the rest are all non-processing parts. The tolerance class of investment casting is required to be GB/T6414-2017 CT6.

The growth of micro-cracks on the surface of castings will reduce the service life. Cracks are not allowed in key parts, which are parts with large wall thickness ratio and machined parts. The customer of this product does not allow hot isostatic pressing to increase the production cost. The biggest technical problem of this rod-shaped titanium alloy casting is to design a reasonable gating system to make the rod-shaped titanium alloy casting φ There shall be no investment casting defects and low residual stress around the 10mm hole and at the rod opening with large wall thickness ratio.