The sand casting industry, integral to manufacturing sectors such as automotive, aerospace, construction, and heavy machinery, is influenced by various market trends and demand fluctuations. Understanding these trends is crucial for industry stakeholders to navigate the market effectively and capitalize on emerging opportunities. Here’s an analysis of the current market trends and demand factors in the sand casting industry:

1. Automotive Industry Demand

- Growth in Vehicle Production: There’s a continuous demand for sand-cast products in automotive manufacturing, especially for engine parts, chassis components, and transmission parts. However, the shift towards electric vehicles (EVs) is changing the types of components needed, with a possible reduction in complexity and number of cast parts.

- Lightweight Materials: There’s an increasing trend towards using lightweight materials to improve fuel efficiency, which might challenge the traditional sand casting industry to adapt to lighter alloys.

2. Infrastructure Development

- Global Construction Growth: The expanding construction industry, particularly in emerging markets, drives demand for sand-cast products used in construction machinery and infrastructure projects.

- Urbanization: Increased urbanization requires extensive civil infrastructure, which in turn increases the demand for sand-cast components like pipe fittings and large structural components.

3. Aerospace and Defense

- High-Performance Requirements: Aerospace applications demand high precision and durability, leading to specialized sand casting industry to produce high-quality aluminum and magnesium alloy parts.

- Increased Defense Spending: Growth in global defense spending also boosts the demand for sand-cast components in military vehicles and equipment.

4. Renewable Energy Sector

- Wind Energy Components: The renewable energy sector, particularly wind energy, utilizes large-scale sand casting industry for components like turbine housings and other large structural parts.

- Sustainable Manufacturing: There’s also a push towards more sustainable manufacturing practices within the sector, influenced by global environmental concerns.

5. Technological Advancements

- 3D Printing and Digital Manufacturing: Adoption of 3D printing for creating complex molds and cores directly from digital models is becoming more prevalent, which could potentially reduce the demand for traditional sand casting industry in certain applications.

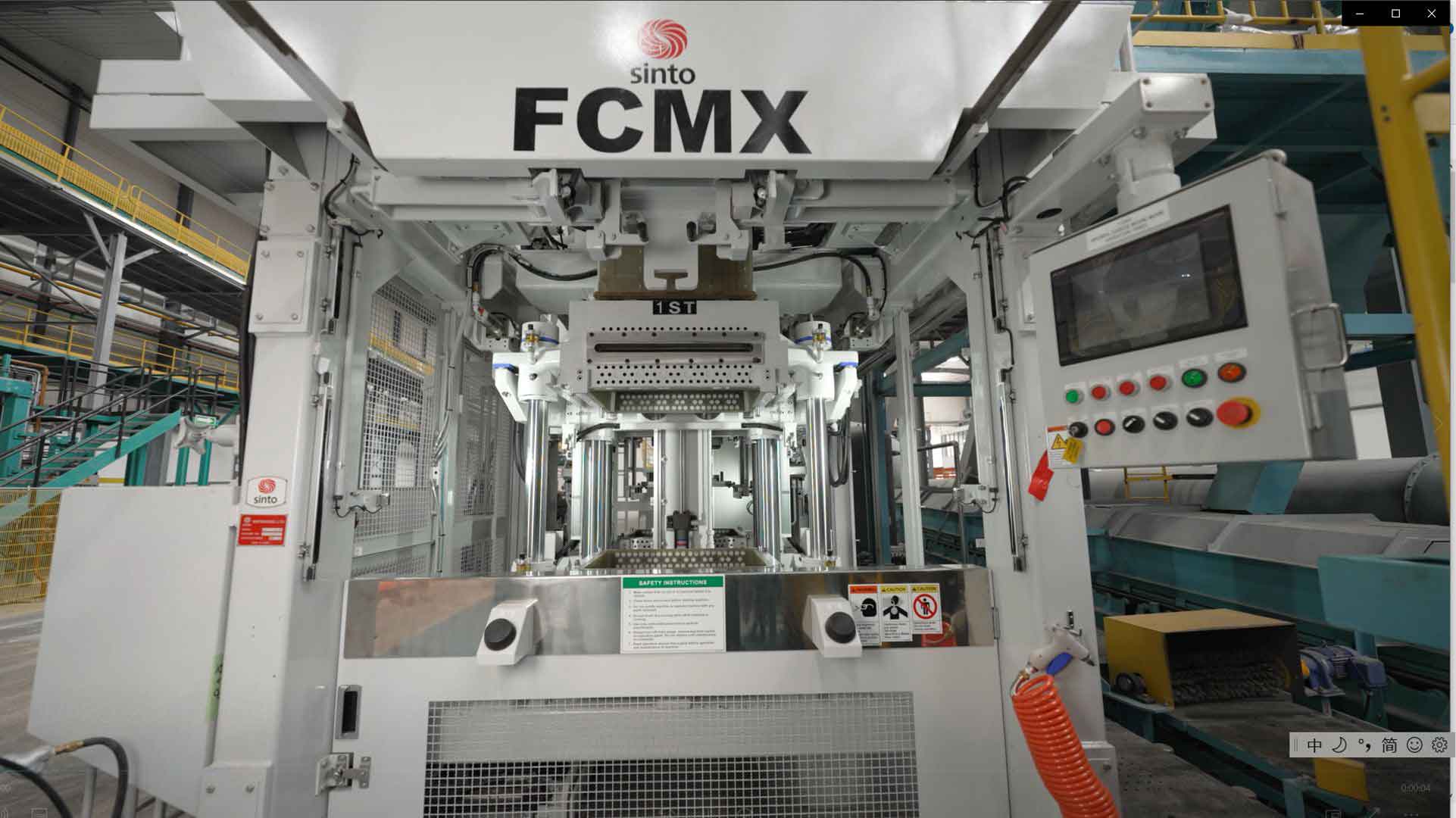

- Automation and Robotics: Increased automation in sand casting industry helps meet the growing demand for precision and efficiency, especially in competitive markets.

6. Supply Chain Innovations

- Global Supply Chain Reconfiguration: Recent disruptions (like those caused by COVID-19) have led to a reevaluation of supply chain strategies, with a focus on resilience and diversification of sourcing to avoid future disruptions.

- Localization: There’s a growing trend towards localizing production to reduce dependencies on international suppliers and to decrease logistic costs.

7. Regulatory and Environmental Pressures

- Environmental Regulations: Stricter environmental regulations are pushing the sand casting industry to adopt cleaner technologies and recycle more of its waste products.

- Carbon Footprint Reduction: Companies are increasingly required to demonstrate reductions in their carbon footprint, influencing the adoption of energy-efficient technologies and practices in casting operations.

8. Economic Conditions

- Global Economic Health: Economic downturns and booms significantly impact the demand for sand-cast products across all industries, with capital-intensive industries like construction and machinery being particularly sensitive to economic cycles.

By staying attuned to these trends, companies in the sand casting industry can better prepare for shifts in demand and technological advancements, ensuring they remain competitive and responsive to market needs. Adaptability, investment in new technologies, and alignment with sustainable practices are key strategies for thriving in this evolving market landscape.