The quenching and tempering treatment of quenched and tempered steel has two major shortcomings: one is that it consumes a lot of materials and human resources and brings pollution; the other is that the quenching and tempering treatment will inevitably cause deformation or even cracking of the workpiece. Improper quenching and tempering will also cause early failure of the parts in the process of use, and quenching deformation increases the difficulty of correction. In order to prevent excessive deformation from affecting the machining size, measures are often taken to increase the finishing allowance, which will reduce the quenching and tempering effect under the surface of the workpiece and increase the manufacturing cost.

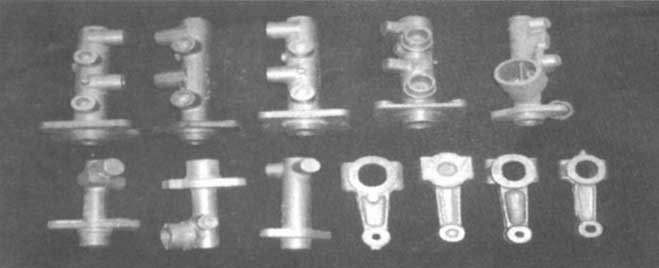

The substitution of non quenched and tempered steel for Quenched and tempered steel is an effective energy-saving measure, which has attracted the attention of more and more domestic enterprises, and has been rapidly developed and applied. Non quenched and tempered steel is a kind of high-efficiency and energy-saving steel developed with the international energy shortage, which is used to replace the traditional quenched and tempered carbon steel or alloy structural steel. Due to the elimination of quenching and tempering process, compared with quenched and tempered steel, it has the advantages of simplifying production process, improving material utilization, improving part quality, reducing energy consumption and manufacturing cost (25% ~ 38%), and can be widely used in automobile connecting rod, crankshaft, camshaft, wheel hub, steering knuckle, shift lever, spline shaft and other parts.

Gb/t 15712-1995 issued by China in 1995 stipulates that: non quenched and tempered mechanical structural steel: medium carbon steel is added with trace alloying elements (V, Ti, Nb, N, etc.) through temperature controlled rolling (forging), temperature controlled cooling and dispersing carbon (nitrogen) compounds in ferrite and pearlite as strengthening phase, so that it will not undergo quenching and tempering treatment after rolling (forging), The mechanical properties of carbon structural steel or alloy structural steel after quenching and tempering can be obtained.