The change diagram of critical solid rate during solidification of lost foam castings is shown in Figure 1. It can be seen from figures a and B that the lost foam casting begins to solidify at t = 21.63s, and the part with thin wall thickness at the lower edge solidifies first. As can be seen from figures B and C, when t = 359.1s, the solid rate is 32% and T = 469.1s, and the solid rate is 49%, the inner sprues in the lower and upper rows of the stepped gating system solidify respectively. As can be seen from Fig. D, finally, isolated liquid phase is formed in the interior of the gating system and the large rotation part of the lost foam casting, where shrinkage porosity and shrinkage cavity defects may appear.

Fig. 2 is the solidification time distribution diagram of lost foam casting, which reflects the solidification time used by various parts of lost foam casting. From the diagram, it can be seen that the part with the longest solidification time, that is, the last solidification part, is in the large rotation part, which is consistent with the reaction of solid phase rate distribution diagram, so it may be necessary to set a riser at this part.

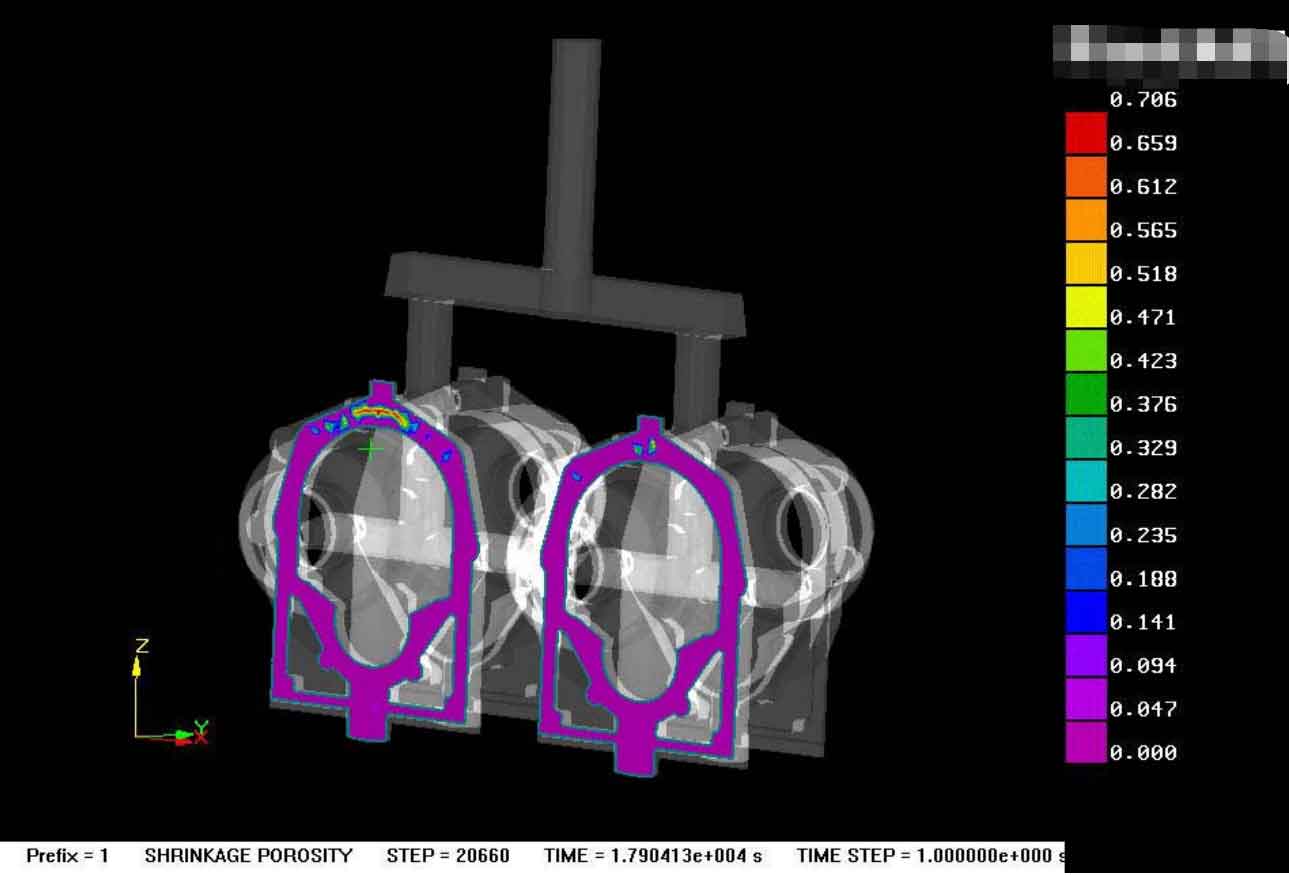

Figure 3 shows the distribution of shrinkage porosity and shrinkage cavity of lost foam castings. According to general engineering experience, the percentage of void volume in total volume is used as the judgment basis, and 5 ‰ is used as the standard to judge shrinkage porosity and shrinkage cavity. It can be seen from the figure that shrinkage porosity and shrinkage cavity are mainly distributed on the rotating body and the side surface of lost foam casting, and there are also a small amount of shrinkage porosity and shrinkage cavity in the gating system, which is basically consistent with the reflection of solid phase rate distribution diagram and solidification time distribution diagram.