The lost foam casting thin-walled gray cast iron gearbox shell casting with the improved gating system is adopted. The qualification rate of the lost foam casting thin-walled gray cast iron gearbox shell casting is low, and there are exposed carbon slag defects after processing. Therefore, we have formulated the optimal design scheme of the gating system in the table for the test.

The test is carried out according to the scheme in the table, and the improvement scheme is as follows:

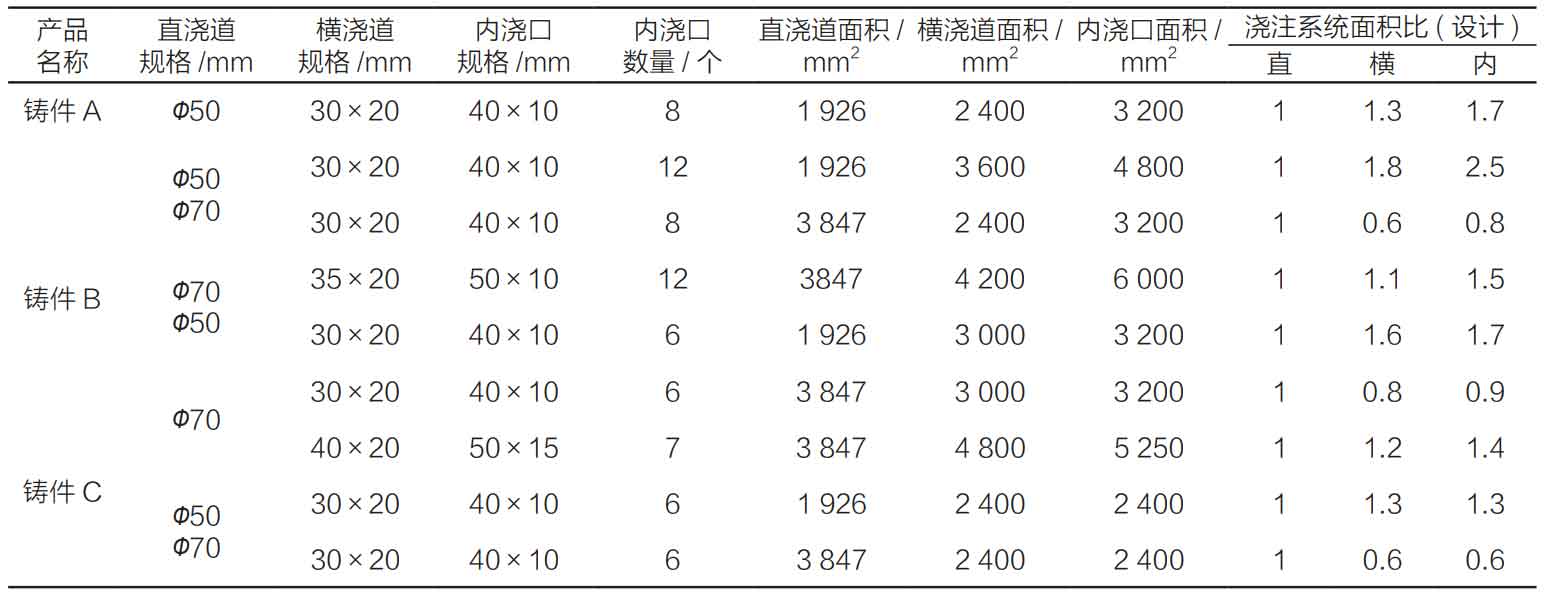

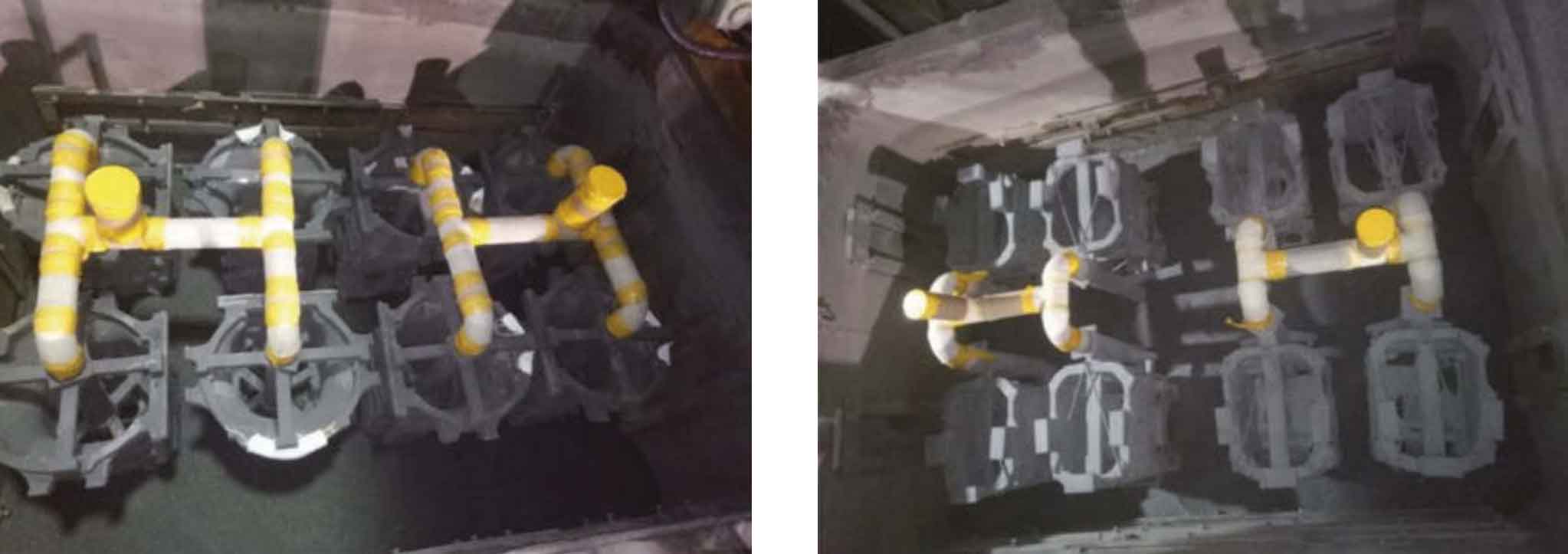

The gating system of lost foam casting thin-walled gray cast iron gearbox shell casting a adopts the meter shaped stepped gating system combining bottom injection, middle injection and top injection. It is poured with double nozzles, and the diameter of the sprue is Ф 70 mm, 35 mm for each product × 6 20 mm transverse runners, size 50 mm × There are 12 10 mm internal gates, and the ratio of the cross-sectional area of the sprue, transverse gate and internal gate is 1 ∶ 1.1 ∶ 1.5. The buried box method is lost foam casting. The pressure bearing area of the thin-wall gray cast iron gearbox shell casting is downward (the large gate is upward), 8 pieces / box, and the pouring mass of a single box is 1143 kg.

Lost foam casting thin-walled gray cast iron gearbox shell casting B gating system adopts a single-sided stepped gating system combining bottom injection, middle injection and top injection. It is poured with double nozzles. The diameter of the sprue is 70 mm and 40 mm × 5 20 mm transverse runners, size 50 mm × There are 7 15 mm internal gates, and the ratio of the cross-sectional area of the sprue, transverse gate and internal gate is 1 ∶ 1.2 ∶ 1.4. The buried box method is lost foam casting. The non pressure area of the thin-walled gray cast iron gearbox shell casting is downward, 8 pieces / box, and the pouring mass of a single box is 1129 kg.

Lost Foam Casting Thin-wall gray cast iron gearbox shell casting C gating system adopts top pouring meter shaped gating system, double nozzle pouring, and the sprue diameter is 50 mm and 30 mm × 4 Nos. of 20 mm runner, size 40 mm × There are 6 10 mm internal gates. The ratio of cross-sectional area of sprue, transverse gate and internal gate is 1 ∶ 1.3 ∶ 1.3. The buried box method is lost foam casting. The non pressure area of thin-wall gray cast iron gearbox shell casting is downward, 16 pieces / box, and the pouring mass of a single box is 1129 kg.

The experimental results show that the open gating system is suitable for the three kinds of lost foam casting thin-wall gray cast iron gearbox shell castings, as shown in Fig. 1 and Fig. 2.