The high appearance quality of lost foam casting products is one of its advantages, but its internal quality is difficult to control, which hinders its wider adoption and application. The internal quality problems of lost foam castings are mainly related to the solidification process characteristics of lost foam castings.

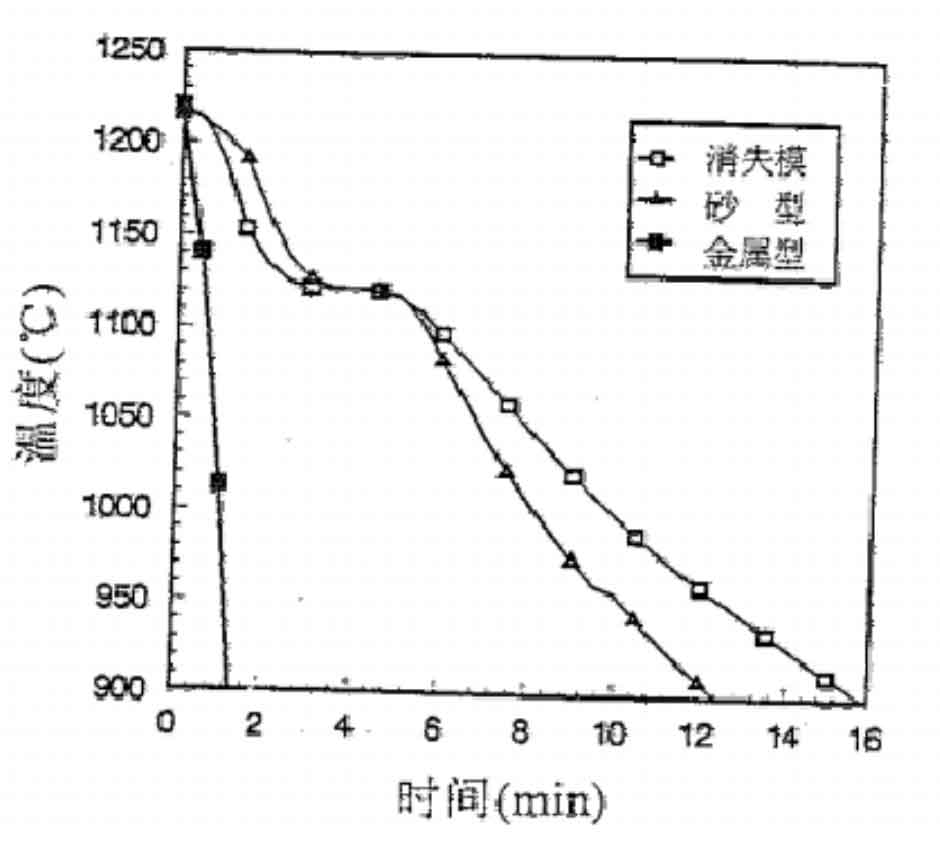

The biggest characteristic of solidification of negative pressure dry sand lost foam casting is that the solidification speed is slower than that of sand casting, which is also the best explanation for the coarser grains of common lost foam castings.

There are many reasons for this slowness, including that the dry sand does not contain water and the heat taken away by the gasification of water in the mold is less; The exhaust products in the mold filling process have an impact on the characteristics of dry sand. On the one hand, it makes the dry sand mold more stable, on the other hand, it affects its heat transfer and makes it thermal insulation; The properties of refractory coating are also different from those of traditional cavity gravity casting. The “slow” solidification will directly lead to the decline of the structure and performance quality of lost foam castings. Therefore, it is particularly important to pay attention to the solidification process of lost foam casting and control the internal quality of products.