1. PLC software design

PLC control software includes interface management program and monitoring program. The interface management program is connected with the communication interface to receive, analyze and process the remote code instructions sent from the communication interface. The parameter codes mainly include relevant scanning functions, operation instructions and working modes. The instrument detection results are sent through the information interface by collecting and processing relevant data Data processing results and current instrument working conditions.

Software programming needs to consider the control object and control task, and design the control electrical schematic diagram. Then the internal components in the electrical schematic diagram are assigned, and finally PLC programming is carried out. PLC programming language includes statement table, ladder diagram, sequential function diagram and function block diagram. After programming, simulate the PLC program and download the simulation program to the storage module for debugging.

2. Configuration of mold filling speed measurement and control system

In the sand casting process of machine tool bed, the PLC control parameters mainly consider the mold filling speed and casting length, and the PLC configuration of measurement and control system. The whole control system mainly includes CPU module cqm1-cpu41, switch button input module D212, D / a output module da021, D / a power module ps02, relay output module oc22, transistor output module od212 and LED display board. The turbine flowmeter drives the encoder to detect the return oil flow, and the return oil flow increases with the increase of the pulse output by the encoder. The PLC counter is connected with the pulse signal output by the encoder. The display panel is divided into three areas, and the actual speed and the set speed are in the same area. When the mold filling speed is set for sand casting, this area displays the set mold filling speed, otherwise, this area displays the actual mold filling speed for sand casting.

In order to avoid stress concentration on the casting surface during sand casting, the filling speed of metal liquid must be controlled. In the past, PI was used to control the filling speed of metal liquid. The fluctuation of filling speed was unstable, resulting in the concentration of filling stress. PLC is used to control the mold filling speed of sand mold casting of machine bed, and the change curve of mold filling speed error is verified by MATLAB software to ensure the minimum mold filling speed error. The filling speed is controlled by PLC, and the filling speed error simulation parameter is set.

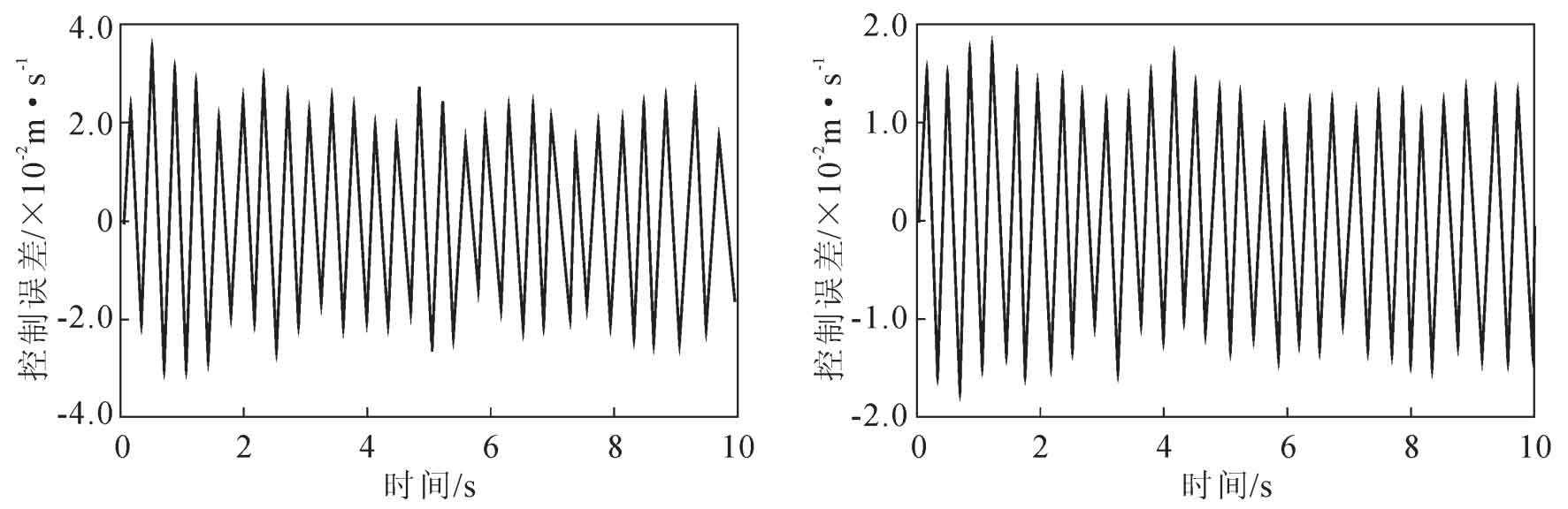

The figure shows the simulation results of PLC and PI mold filling speed error. It can be seen that the maximum error is 1.8 when PLC is used to control the filling speed of sand casting on the machine bed × 10-4m / s, the mold filling speed is relatively stable, and the stress concentration is not obvious. PI is adopted to control the filling speed of sand mold casting on the machine bed, and the maximum error is 3.6 × 10-2 M / s, the mold filling speed is unstable, the stress distribution is relatively concentrated, and the casting surface is prone to deformation and crack. Therefore, using PLC to control the mold filling speed of sand casting on the machine bed can ensure the stable pouring of metal liquid into the mold cavity and avoid the decline of comprehensive mechanical properties of the casting surface caused by stress concentration.