Shrinkage and porosity defects are common defects in sand casting production. The main purpose of numerical simulation of temperature field in solidification process is to predict the possible shrinkage and porosity defects in sand casting, so as to control the internal quality of sand casting and optimize the sand casting process. For different sand castings, because of their different solidification characteristics, the mechanism of shrinkage and porosity in the solidification process is not exactly the same. Therefore, in order to predict the formation of shrinkage cavity and porosity in the solidification process of sand castings, it is necessary to study the generation mechanism of shrinkage cavity and porosity of different sand casting materials and put forward the corresponding prediction criteria of shrinkage cavity and porosity.

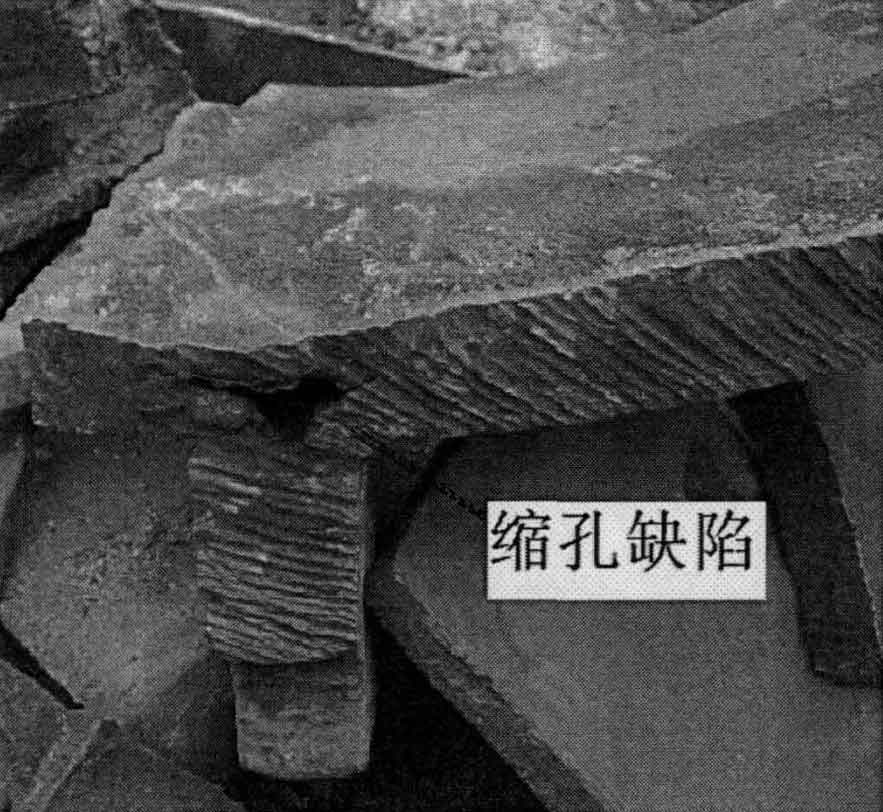

When the liquid metal liquid fills the mold, the liquid metal in contact with the internal surface of the mold forms a closed hard shell due to the decrease of temperature. If the runner is partially solidified, the metal in the hard shell will produce liquid shrinkage and solidification shrinkage. This causes the liquid level in the hard shell to drop, and the hard shell will also form solid shrinkage with the decrease of temperature. Under the action of gravity, the metal level in the hard shell decreases and the remaining liquid metal decreases. When all the liquid metal solidifies, shrinkage cavities will appear under the hard shell on the upper part of the sand casting. As the residual liquid metal cannot be fed during solidification, shrinkage cavity will be accompanied by porosity. The shrinkage cavity defect of sand casting is shown in the figure.